Other Control Valves

73-73 of 73 results

CNCV-240426-UCV-01

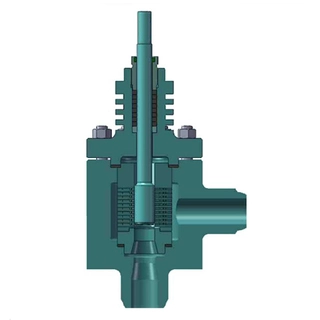

Introducing our Labyrinth Control Valve, crafted from sturdy ASTM materials like A216 WCB, WCC, A217 WC6, WC9, and A105. Featuring ANSI B16.104 Class V leakage standards with metal seats (standard) and Class VI (optional) with soft seats. Available with flange or welding connections, its trim includes an unbalanced design, a labyrinth cage combination, and quick tear-down capability. Offering sizes from 3/4 inch to 12 inches (DN20-DN300) and pressure ratings from Class 150 LB to 2500 LB (PN16-PN420, 1.6-42.0 Mpa), with a rangeability of 30:1. Suitable for temperatures ranging from -196℃ to 538℃, it provides precise control with equal percentage or linear flow characteristics.