Control valve is a crucial device used in fluid handling systems to regulate flow rates. It consists of a valve body, an actuator, and a control mechanism. By adjusting the position of the valve plug or disk, it controls the flow of fluids such as water, gas, or oil. Control valves are essential in various industries, including manufacturing, oil and gas, and chemical processing, where precise control of flow, pressure, and temperature is necessary for optimal operation.

Control valves are integral components in industrial systems, playing a critical role in directing the flow of gases, steam, water, and chemicals. They are designed to respond to changes in system pressure, flow, temperature, or other process variables, ensuring that these variables remain as close as possible to their desired set points. By regulating the flow, control valves help maintain optimal operational conditions, minimize energy usage, and ensure safety and efficiency across various processes. Our diverse portfolio of control valves is engineered to deliver maximum performance and compliance with the highest industry standards, ensuring reliability and precision in all types of applications.

Control valve actuators are the devices responsible for converting input energy (such as air, liquid, or electricity) into mechanical force, which moves the valve mechanism. The actuator controls the opening or closing of the valve based on the system's demands, enabling precise regulation of flow and pressure. There are several types of actuators, each suited for different applications and operating conditions. These include pneumatic, hydraulic, and electric actuators.

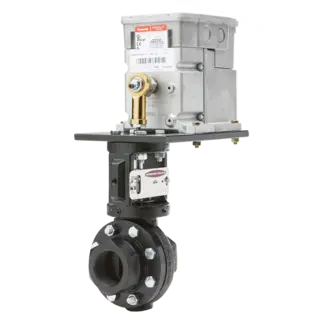

Pneumatic actuators use air pressure to create force, typically through a flexible diaphragm or piston. When compressed air is applied, it pushes against the diaphragm or piston, moving the valve mechanism. Pneumatic actuators are widely used due to their simplicity, reliability, and rapid response times. They are particularly well-suited for applications requiring frequent or high-speed operation. The following image illustrates a cut-away control valve with a pneumatic diaphragm actuator positioned above the valve body.

In contrast to pneumatic actuators, hydraulic actuators rely on liquid pressure to generate mechanical force. These actuators typically use a piston to convert the hydraulic pressure into movement, offering higher force output due to the dense nature of liquids compared to air. Hydraulic actuators are particularly effective in high-pressure systems and are often used in industrial applications where high forces are required. The lubricating properties of hydraulic oil also help reduce friction, making them suitable for long-term, high-performance operations.

Electric actuators utilize electric motors to drive valve mechanisms. This actuator type has been employed for decades in large valves and shutoff applications. Recent advances in motor design and control electronics have made electric actuators competitive with pneumatic actuators, even for throttling applications that require more precise control. Electric actuators offer the advantage of precise position control, easy integration with control systems, and the ability to operate in a wide range of environments.

The actuator connects to the valve stem, which provides the force necessary to open, close, or modulate the valve. The actuator works in conjunction with a control system to adjust the valve position based on process feedback. This feedback typically comes from sensors that measure variables such as flow rate, pressure, temperature, or level, which then inform the actuator’s response.

Pneumatic Actuators are generally the most commonly used and are known for their reliability and speed in operation. Their ability to quickly respond to system changes makes them a preferred choice for many industries.

Control valves come in a variety of designs, each suited to specific types of applications and flow characteristics. Some of the most common types include:

Globe valves are designed to provide precise flow control, typically used in applications that require throttling of flow. The globe valve's design allows for smooth, incremental adjustments to flow and pressure.

These valves are compact and versatile, offering rapid response and are commonly used in systems where space is limited or where a fast-acting valve is required. The quarter-turn operation allows for easy modulation of flow.

V-port ball valves have a special "V" shaped ball that allows for more precise flow control. They are typically used for applications that require a higher degree of accuracy in regulating the flow.

These valves are designed for applications that require precise flow control with minimal turbulence. Their eccentric plug provides more uniform flow control, reducing the risk of flow-induced vibrations.

These valves are designed with reduced trim, offering a high rangeability and effective throttling. Their robust construction is ideal for handling aggressive fluids in challenging environments.

Each valve type offers distinct advantages depending on the specific needs of the application, including factors such as flow capacity, pressure rating, and response time. By selecting the right type of control valve, industries can ensure efficient and reliable operation across a wide range of systems and applications.