Other Control Valves

61-72 of 73 results

The self-operated temperature control valve uses the principle of liquid thermal expansion to achieve automatic adjustment without an auxiliary actuator. The liquid in the temperature sensor expands uniformly. This valve controls the medium's temperature by expanding or contracting the temperature-sensitive liquid in the sensor, thus adjusting the valve opening. When the medium's temperature exceeds the set value, the liquid expands, pushing the spool down to close the valve and reduce thermal media flow. When the temperature falls below the set value, the liquid contracts, and the reset spring pushes the spool to open, increasing the flow. This valve is used in heating, air conditioning, domestic hot water, petrochemical, electric power, textile, rubber, food, and other industries.

The pressure reducing valve is designed for parallel water supply systems serving both firefighting and domestic needs. In the event of a fire, it prioritizes water flow to firefighting efforts by automatically cutting off the domestic supply, ensuring adequate water for emergency response. Once firefighting operations cease and water pressure stabilizes, the valve reopens to restore the domestic supply. This mechanism eliminates the need for a separate dedicated firefighting water pipeline, significantly reducing construction costs and water usage. Ideal for integrated water management, this valve ensures efficient and reliable water distribution in critical situations.

Constructed from durable materials such as ductile cast iron, cast steel, and stainless steel, our pressure relief/sustaining control valve is available in sizes ranging from DN50 to DN800 (2 inches to 32 inches). It supports pressure ratings of PN10, PN16, and PN25, with flanged end connections for easy installation. This versatile valve system includes a main valve, a pressure relief/sustaining pilot valve, a needle valve, a ball valve, a microform filter, and a pressure gauge. It operates hydraulically, offering dual functionality as a pressure relief valve—maintaining water supply pressure below a preset safety limit—and as a pressure sustaining valve—ensuring upstream pressure remains above a specified value for consistent water supply.

Introducing the Flow Control Valve, available in sizes DN25-DN800 with PN10, PN16, PN25 pressure ratings and flanged ends for easy installation. Suitable for medium temperatures ranging from 0°C to 80°C, it's crafted from durable materials like ductile cast iron, cast steel, and stainless steel. Ideal for pipeline applications requiring precise flow and pressure control, this valve maintains consistent flow, limits excessive flow, and adjusts upstream high pressure effectively. It ensures downstream flow remains unaffected by upstream pressure changes and offers emergency flow cutoff capabilities to prevent losses. With high sensitivity, safety, reliability, easy commissioning, and long service life, it is a versatile solution for various industrial needs.

Introducing our Differential Pressure Bypass Valve, designed for air conditioning systems. Available in sizes DN50-DN800 (2 Inch - 32 Inch) and pressure ratings PN10, PN16, PN25, with flanged ends for easy installation. This valve effectively regulates differential pressure between supply and feedback water, ensuring optimal system performance. By maintaining a fixed value, it enhances system efficiency, reduces noise, and protects equipment from excessive pressure differentials. Ideal for improving system utilization and ensuring long-term reliability in air conditioning applications.

Offering a range of 3/4 to 1-1/4 Inch, our valves boast a design pressure of PN160. With NPT connections, they operate in Electric Regulating or Electric Switching modes. Featuring a Needle Valve Seat structure, these valves are compact and lightweight. Crafted from forged raw materials, they exhibit exceptional pressure resistance, with disassemblable internal parts for cost-effective maintenance, ensuring equipment stability and leak prevention. Electric actuators deliver precise regulation, controlling flow rates for water molecule separation and discharge. They also mitigate cavitation, noise, and piping vibration. Labyrinth-type valve cages offer multi-stage pressure reduction with adjustable ratios up to 100:1, ensuring no external leakage with double sealing. Various electric actuator models are available to accommodate a range of pressure drops.

The Servomotor Control Valve, meticulously crafted for precise pressure regulation within reverse osmosis setups, stands as a pinnacle of engineering excellence. Our top pick boasts unparalleled corrosion resistance, purposefully tailored for RO system applications. Crafted from AISI 904L stainless steel with AISI 316 SS internals, it ensures durability and reliability. For harsher environments, options include duplex stainless steel or Hastelloy valves. Additionally, customization extends to electric actuators, with choices ranging from special 3-point to 4-20 mA variants, ideal for seawater installations. Trust in our expertise for optimal performance and longevity in your water treatment systems.

Our electric control valves adhere to ANSI/ISA 75.01.01 and ASME B16.34 design standards, with face-to-face dimensions per ASME B16.10 and flanges conforming to ASME B16.5. Available in sizes from 1 to 24 inches (DN25-DN600) and ANSI classes 150 LB-2500 LB (PN20-PN420), these valves are vital for industrial automation. They are widely used in oil, chemicals, power generation, and pharmaceuticals. Our experts provide comprehensive guidance on selecting the best model parameters and operational conditions to ensure optimal performance for your specific needs.

Introducing the Electric Actuated Control Valve, meeting ANSI/ISA 75.01.01 & ASME B16.34 standards, constructed with ASTM A216 WCB body materials. Compliant with ASME B16.10 face-to-face and B16.5 flange standards, available in sizes ranging from 1 inch to 24 inches (DN 25 to DN 600). With ANSI Class ratings from Class 150 LB to 2500 LB and pressure ratings from PN20 to PN420, these valves are essential in oil, chemical, power generation, and pharmaceutical industries. Our expert guidance ensures optimal selection and utilization tailored to your specific needs.

Our comprehensive range of pneumatic and electrically actuated control valves ensures precise control for fractional flow applications. Designed to optimize performance, these valves are ideal for critical micro-flow tasks in various settings including pilot plants, test stands, R&D facilities, processing plants, and specialized operations such as dosing, injection, and venting. With their accuracy and reliability, they offer enhanced control over fluid processes, guaranteeing efficiency and quality across diverse industrial applications.

Our range of two and three-way valves presents a broader spectrum of options than any other valve family in the industry. These versatile stem-guided control valves are ideal for various industrial applications. With a modular design, multiple trim styles, and a diverse selection of materials, there's a valve tailored to almost every need. Available in both ANSI and DIN standards, ensuring seamless direct replacements, our valves guarantee adaptability across different systems.

CNCV-240426-UCV-02

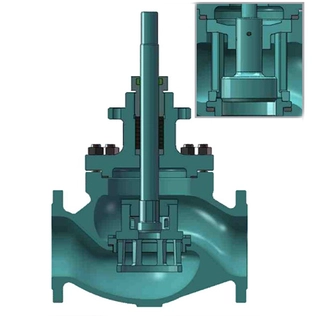

Introducing our Pressure Relief Control Valves, engineered with durability in mind using ASTM materials like A216 WCB, WCC, A217 WC6, WC9, and A105. Featuring versatile trim options such as unbalanced pressure relief, seat-guided, and top-guided trims, alongside quick tear-down capability. Available in sizes ranging from 3/4 inch to 12 inches (DN20-DN300) and suitable for pressure ratings from PN16 to PN160 (1.6-16.0 Mpa, Class 150 LB - 900 LB). Offering a wide temperature range from -196℃ to 538℃, leakage conforms to ANSI B16.104 Class VI standards with optional soft seat. Connection options include flange or welding, while the flow characteristic is quick opening, ensuring efficient performance.