Hydraulic Flow control valve, DN25-DN800, Ductile Cast Iron

Key Specifications / Features

Hits: 15

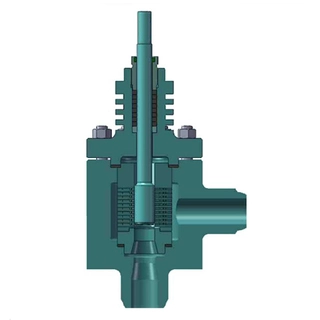

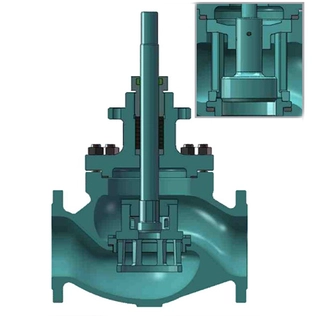

Introducing the Flow Control Valve, available in sizes DN25-DN800 with PN10, PN16, PN25 pressure ratings and flanged ends for easy installation. Suitable for medium temperatures ranging from 0°C to 80°C, it's crafted from durable materials like ductile cast iron, cast steel, and stainless steel. Ideal for pipeline applications requiring precise flow and pressure control, this valve maintains consistent flow, limits excessive flow, and adjusts upstream high pressure effectively. It ensures downstream flow remains unaffected by upstream pressure changes and offers emergency flow cutoff capabilities to prevent losses. With high sensitivity, safety, reliability, easy commissioning, and long service life, it is a versatile solution for various industrial needs.

Request a quote

Tags

Detail Information

SPECIFICATIONS

Product Name: Hydraulic Flow Control Valve

Features: Hydraulic Self-control, Easy Maintenance, and Stable Flow Control.

Size: DN50-DN800, 2 Inch - 32 Inch

Pressure Rating: PN10, PN16, PN25

Connection: Flanged Ends

Medium Temperature: 0°C to 80°C

Body Material: Ductile Cast Iron, Cast Steel, Stainless Steel

Maintenance Instructions For Flow Control Valve:

The hydraulic control valve features a self-lubricating valve body using water, eliminating the need for additional oil lubrication. In case of damage to internal parts, follow the disassembly instructions below.

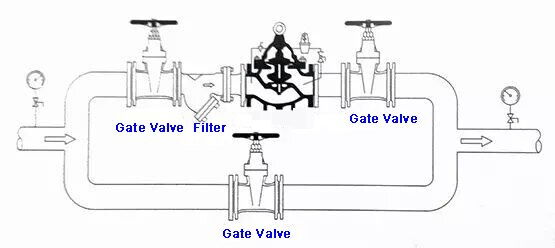

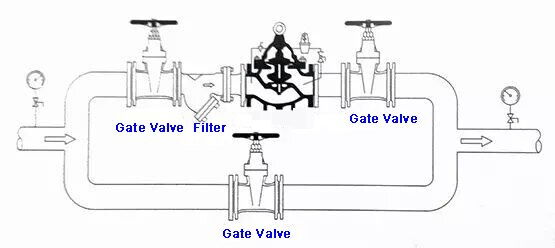

1. Close the upstream and downstream gate valves of the main valve.

2. Loosen the screws of the piping connector on the main valve cover to release internal pressure.

3. Remove all screws, including copper tubing and nuts in the control line.

4. Take off the cover and spring.

5. Remove the plug and diaphragm carefully, avoiding damage.

6. Inspect the diaphragm and gasket for damage; if intact, avoid further disassembly.

7. If damaged, loosen the nut on the plug, disassemble and replace the diaphragm or gasket.

8. Check for damage to the valve seat and plug, and clean any debris.

9. Reassemble the parts in reverse order, ensuring the valve moves freely.

10. Refer to installation notes for reuse.

Product Name: Hydraulic Flow Control Valve

Features: Hydraulic Self-control, Easy Maintenance, and Stable Flow Control.

Size: DN50-DN800, 2 Inch - 32 Inch

Pressure Rating: PN10, PN16, PN25

Connection: Flanged Ends

Medium Temperature: 0°C to 80°C

Body Material: Ductile Cast Iron, Cast Steel, Stainless Steel

Maintenance Instructions For Flow Control Valve:

The hydraulic control valve features a self-lubricating valve body using water, eliminating the need for additional oil lubrication. In case of damage to internal parts, follow the disassembly instructions below.

1. Close the upstream and downstream gate valves of the main valve.

2. Loosen the screws of the piping connector on the main valve cover to release internal pressure.

3. Remove all screws, including copper tubing and nuts in the control line.

4. Take off the cover and spring.

5. Remove the plug and diaphragm carefully, avoiding damage.

6. Inspect the diaphragm and gasket for damage; if intact, avoid further disassembly.

7. If damaged, loosen the nut on the plug, disassemble and replace the diaphragm or gasket.

8. Check for damage to the valve seat and plug, and clean any debris.

9. Reassemble the parts in reverse order, ensuring the valve moves freely.

10. Refer to installation notes for reuse.

Installation of Flow Control Valve

Comment Form