Products

337-348 of 348 results

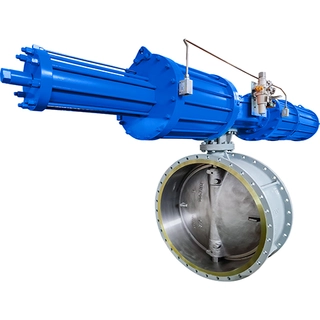

Model No.: CNCV-240425-BFCV-02

Explore our range of triple eccentric butterfly control valves, meticulously crafted from high-quality materials such as ASTM A216 WCB, WCC, ASTM A351 CF8, CF3, CF8M, and CF3M. With seat leakage designed to meet ANSI B16.104 Class VI standards, these valves ensure reliable performance and tight shut-off. Available in sizes ranging from 2 to 48 inches and pressure classes from 150 to 600 LB, they offer versatility and durability for various industrial applications.

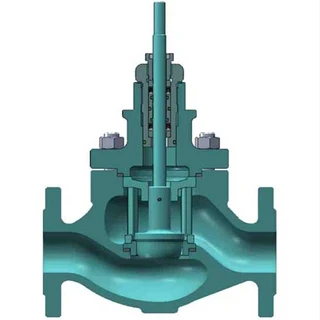

Model No.: CNCV-240425-BCV-01

Discover our assortment of balanced cage-guided control valves, offered in sizes from 1-1/2 inches to 16 inches and pressure ratings from Class 150 to 600 LB. Constructed from robust materials like carbon steel, alloy steel, and stainless steel, ensuring dependable performance across diverse industrial environments. Featuring seat leakage compliance with ANSI B16.104 Class IV, V, and VI standards, our valves ensure precise control and efficient flow regulation.

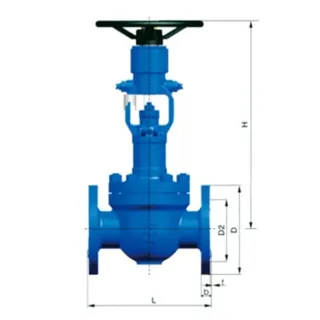

Model No.: CNCV-240425-UCV-01

Explore our range of top-guided unbalanced single-seat control valves, offered in sizes from 3/4 inch to 12 inches and pressure ratings from Class 150 to 2500 LB. Crafted from premium materials like ASTM A216 WCB, WCC, A217 WC6, WC9, and ASTM A105, ensuring dependable performance and accurate control in diverse industrial settings. Select from flanged or welded configurations tailored to your exact needs.

Introducing our Duplex Butterfly Control Valve, available in sizes ranging from 2 inches to 24 inches. Crafted from a selection of top-quality materials including Bronze, Duplex Stainless Steel, Carbon Steel, or 316 Stainless Steel. With ANSI Classes ranging from CL150 to CL600, they assure robust performance under various pressures. Designed with Flanged connection ends for easy installation. Features include a double offset seat for precise control and high performance. Elevate your control systems with our Duplex Butterfly Control Valve, engineered for reliability and efficiency.

Introducing the API 6D Ball Control Valve, engineered to thrive in temperatures ranging from 46°C to 200°C. Crafted from a robust selection of materials including ASTM A216 WCB, WCC, A217 WC6, WC9, and ASTM A351 CF8, CF8M, CF3, CF3M. Available in a wide range of nominal diameters from DN15 to DN800, catering to diverse industrial needs. Its versatility extends to pressure ratings including ANSI Class 150 LB, 300 LB, 600 LB, and DIN PN16, PN25, PN40, PN63, PN100, ensuring reliable performance across various applications.

Introducing our Double Eccentric Plug Control Valve lineup, crafted from ASTM A216 WCB, WCC, CF8, CF8M, A352 LC3 and ASTM A3 materials. Available in sizes ranging from 1 to 4 inches (DN25 to DN100), they offer versatility and precision. With ANSI Class 150 LB and PN25 ratings, they ensure reliable performance under varying pressures. Featuring trim options including CF8, CF8M, and CF8M+No.6, and seat materials SS 304, SS 316, SS 316+No.6, and 316+PTFE, they cater to diverse applications. Stem materials SS 316 (0Cr18Ni12Mo2Ti) and 17-4PH provide strength and durability. Trust our Double Eccentric Plug Control Valves for efficient and dependable operation.

We specialize in exporting Cast Carbon Steel Angle Control Valves, featuring ASTM A216 WCB material, PN16 pressure rating, and DN15 size. Our valves are equipped with a specially designed handwheel and boast a unique 90-degree outlet configuration. They adhere to DIN EN 558-1:1995 for face-to-face dimensions and DIN EN 1092-1:2002 for flanged ends. Welded ends meet DIN EN 12627 standards, ensuring robust construction. Our products comply with DIN EN 13709:2002, guaranteeing quality and performance. Trust our Angle Control Valves for precision, reliability, and adherence to international standards.

Manufacturer of Wafer Butterfly Control Valves, offering ANSI Class 150 to 600 LB. Features a double offset seat mechanism, available in sizes ranging from 2 to 24 inches. Crafted from durable materials including bronze and duplex stainless steel. Choose from body materials such as bronze, duplex stainless steel, carbon steel, or 316 stainless steel, ensuring versatility across applications.

Introducing our Diaphragm Control Valves, crafted from a variety of robust materials including ASTM A216 WCB, ASTM A216WC6, ASTM A352 LCB, ASTM A351 CF8, ASTM A351 CF8M, ASTM A351 CF3M, and ASTM A351 CF3. Available in Cast Globe Valve and Straight-through body types, with nominal sizes ranging from 3/4 inch to 1-1/4 inch. Pressure ratings span ANSI Class 125, 150, 300, and 600 LB, ensuring versatility across applications. Choose from a range of end connections including Flanged End options such as FF, RF, RJ, and LG, as well as Welded End choices like SW and BW, and Threaded End variants such as Threaded, RC, and NPT. Experience precision and reliability with our Diaphragm Control Valves.

Introducing our Level Globe Control Valve lineup, meticulously crafted from a range of top-quality materials including ASTM A216 WCB, SS 304, SS 316, CF8M, CF3M, CF3, CF8, LCB, LCC, 2205 Duplex Stainless Steel, and more. Available in sizes ranging from 1 Inch to 20 Inch, catering to diverse industrial needs. These valves boast ANSI ratings of up to 150, 300, 600, 900, 1500, and 2500 LB, ensuring reliable performance in various pressure environments. Choose from versatile connection options including Flanged, Butt-welded, Socket-welded, and Threaded configurations. Elevate your control systems with our Level Globe Control Valve series, engineered for precision and durability.

Introducing our Ball Control Valve, featuring a sturdy ASTM A216 WCB body and bonnet, along with ASTM A193 B7 bolts. Designed to meet ASME B16.34 standards, ensuring reliability and performance. Face-to-face dimensions adhere to ASME B16.10 specifications, guaranteeing compatibility. Choose from versatile end connections, including Flanged ends compliant with ASME B16.5 and Welded ends meeting ASME B16.25 standards. Experience precision engineering and quality craftsmanship with our API 598 Ball Control Valve, ideal for a wide range of industrial applications.

Introducing our Butterfly Control Valves, spanning sizes from 3 inches to 72 inches, ideal for diverse applications. Operating across an extensive temperature range from -196 °C to 550 °C (-320 °F to 1022 °F), they're built for versatility. With ANSI ratings of 150/300/600/900 LB, they ensure reliability under varying pressures. Adhering to ASME B16.34 standards for design and pressure requirements, they come in Wafer, Lug, and Flange body styles, meeting diverse installation needs. Engineered with precision, they feature ASME B16.34 body shell thickness and API 609/ISO 5752 face-to-face dimensions. Additionally, they boast fire safety certifications, complying with API 607 and ISO 10497 standards. Trust our Butterfly Control Valves for efficiency and safety.