Single-Seated Globe Control Valve, CF8M, 8 Inch, 150-600 LB

Key Specifications / Features

Hits: 25

As a leading manufacturer of Single-Port Globe Control Valves, we offer low leakage, cage-guided valves specifically designed for general control applications across a wide range of temperatures and pressure drops. Our 8-inch valves, rated Class 150-600 LB and compliant with ASME B16.34, are constructed from durable ASTM A352 LCC and ASTM A216 WCB materials, ensuring robust performance and longevity.

These valves feature an upper piston ring seal and metal-to-metal seating, making them ideal for applications demanding low leakage rates. For applications requiring tight shutoff, our valves are available with composition seating (TFE). Alternatively, for higher temperature applications, metal-to-metal seating provides enhanced durability and reliability. With flanged ends for secure installation, our Single-Port Globe Control Valves deliver exceptional control and performance, meeting stringent industry standards.

Request a quote

Tags

Detail Information

SPECIFICATIONS

Product Name: Single Seated Globe Control Valve

Size: 8 Inch

Pressure Rating: Class 150 LB, Class 300 LB, Class 600 LB

Body Materials: ASTM A352 LCC, ASTM A216 WCB, WCC, ASTM A217 WC9, C5, Monel, ASTM A351 CF8M SST

Trim Materials: Stainless Steel 316, Tungsten Carbide, Stellite Overlay, Cobalt, Ceramic

Seats: Metal, PTFE

End Connections:

ANSI Flanges

Raised Face or Ring Type Joint Flanges as per ASME B16.34 Latest Edition

Shutoff: ANSI Class IV & V, ANSI Class II & III

Maximum Inlet Pressure & Temperature: consistent with ASME Class per ASME 16.34

Maximum Pressure Drops: all valves are capable of full rated pressure drops

Flow Characteristics: Quick Opening, Linear, Equal Percent

Trim Options: Noise abatement, Anti-cavitation

Flow Direction:

Normally Down, Linear, Quick Opening, Equal Percent

Always up, Noise Abatement

Always Down, Anti-Cavitation

Valve Travel Indication: Valves are supplied with Visual Travel Indicator

Features & Benefits

1. Easy Maintenance: Top entry cage design allows for convenient in-line maintenance.

2. Efficient Operation: Balanced plug enables the use of smaller actuators.

3. Flow Control Options: Offers characterized flow options including equal percentage, linear, and quick opening.

4. Material Versatility: Available in various body and trim materials, suitable for liquids, gases, or steam applications.

5. High Pressure Handling: Cage guiding ensures stability and allows the Mark E to manage high pressure drops.

6. Sour Service Compatibility: Optional compliance with NACE MRO175/ISO15156-2009 standards.

7. Reliable Sealing: Provides tight shutoff for enhanced performance.

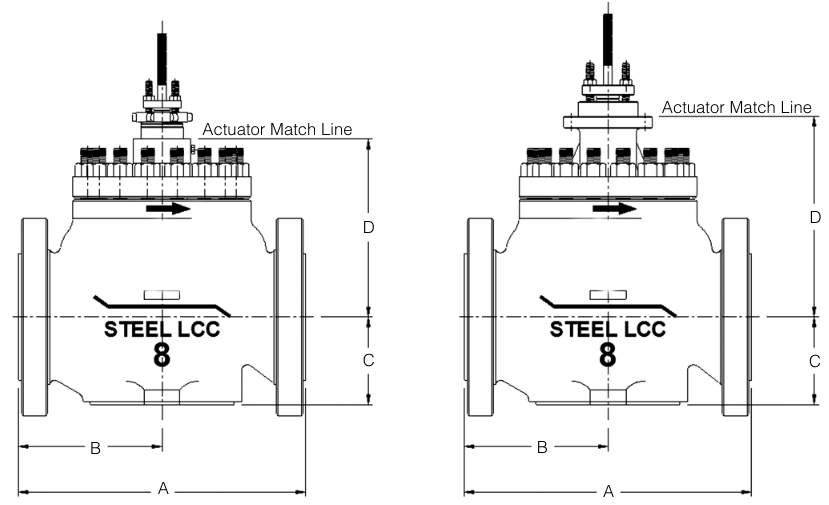

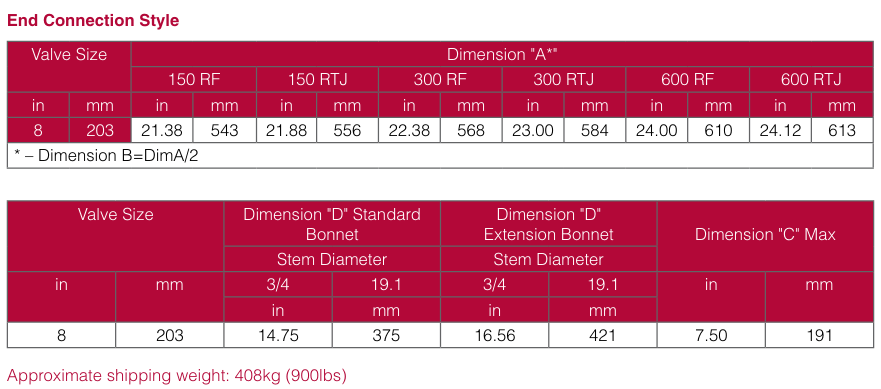

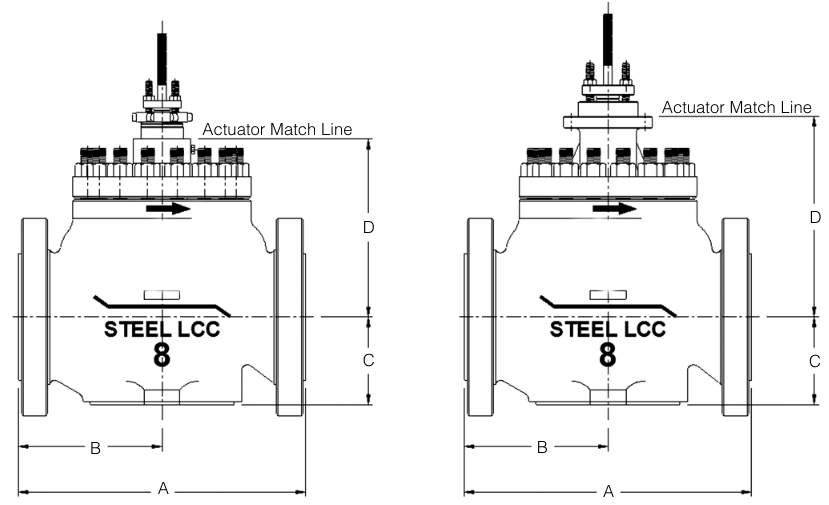

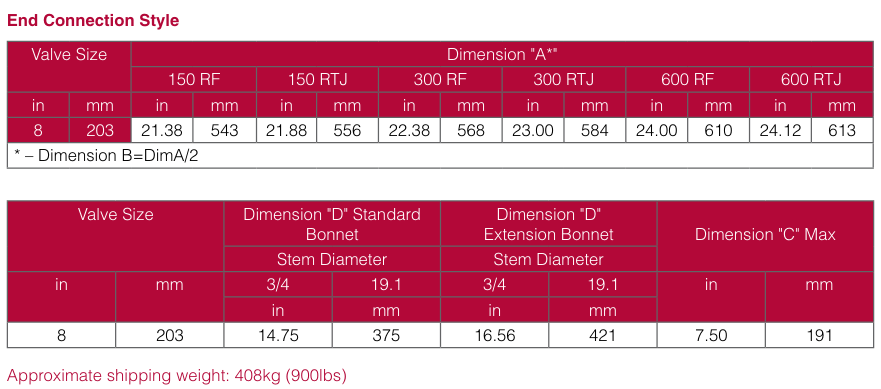

Dimensions

Product Name: Single Seated Globe Control Valve

Size: 8 Inch

Pressure Rating: Class 150 LB, Class 300 LB, Class 600 LB

Body Materials: ASTM A352 LCC, ASTM A216 WCB, WCC, ASTM A217 WC9, C5, Monel, ASTM A351 CF8M SST

Trim Materials: Stainless Steel 316, Tungsten Carbide, Stellite Overlay, Cobalt, Ceramic

Seats: Metal, PTFE

End Connections:

ANSI Flanges

Raised Face or Ring Type Joint Flanges as per ASME B16.34 Latest Edition

Shutoff: ANSI Class IV & V, ANSI Class II & III

Maximum Inlet Pressure & Temperature: consistent with ASME Class per ASME 16.34

Maximum Pressure Drops: all valves are capable of full rated pressure drops

Flow Characteristics: Quick Opening, Linear, Equal Percent

Trim Options: Noise abatement, Anti-cavitation

Flow Direction:

Normally Down, Linear, Quick Opening, Equal Percent

Always up, Noise Abatement

Always Down, Anti-Cavitation

Valve Travel Indication: Valves are supplied with Visual Travel Indicator

Features & Benefits

1. Easy Maintenance: Top entry cage design allows for convenient in-line maintenance.

2. Efficient Operation: Balanced plug enables the use of smaller actuators.

3. Flow Control Options: Offers characterized flow options including equal percentage, linear, and quick opening.

4. Material Versatility: Available in various body and trim materials, suitable for liquids, gases, or steam applications.

5. High Pressure Handling: Cage guiding ensures stability and allows the Mark E to manage high pressure drops.

6. Sour Service Compatibility: Optional compliance with NACE MRO175/ISO15156-2009 standards.

7. Reliable Sealing: Provides tight shutoff for enhanced performance.

Dimensions

Comment Form