Cage Guided Globe Control Valves, Single-seated, 150-900 LB

Key Specifications / Features

Hits: 13

Introducing our Cage Guided Globe Control Valves, specifically designed for superior pressure and flow regulation in steam, gas, and various liquid processes. These single-seated, anti-cavitation valves conform to ASME B16.34 standards and are available in ASTM A352 LCC and ASTM A216 WCB materials.

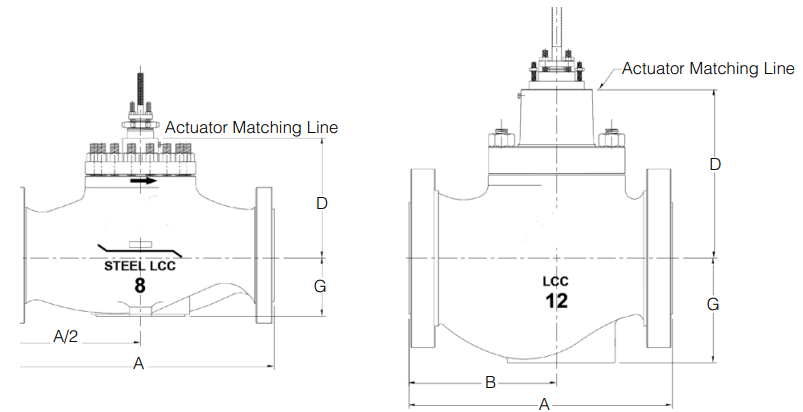

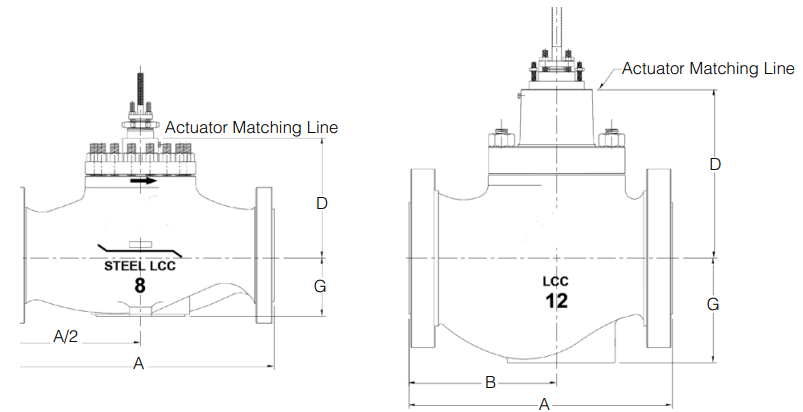

With flanged bodies rated from 150 to 900 LB, these valves feature a globe-style body with cage guiding, clamped seat rings, and push-down-to-close valve plug action. They are equipped with large end connections and expanded internal flow cavities, offering sizes ranging from 8x6 to 24x20 inches, where the first number indicates the line size and the second the trim and bonnet size.

Ideal for a wide range of temperatures and pressure drops, these valves ensure reliable performance with a balanced valve plug and metal-to-metal seating, making them perfect for general control applications.

Request a quote

Tags

Detail Information

SPECIFICATIONS

Product Name: Cage Guided Globe Control Valve

Key Features: Single-seated, Anti-Cavitation, Cage-guided

Sizes: 8×6 Inch, 10×8 Inch, 12×6 Inch, 12×8 Inch, 16×12 Inch, 20×16 Inch, 24×16 Inch, 24×20 Inch

Pressure: Class 150 LB - 900 LB

Body Materials: ASTM A352 LCC, ASTM A216 WCB, WCC, ASTM A217 WC9, C5, Monel, ASTM A351 CF8M SST

End Connections: Raised Face, Ring Type Joint and Welded Flanges

Trim Materials:

Standard Material: Stainless Steel SS 316

Optional Material: Alloy 6, Cobalt, Tungsten Carbide

Seats: Metal and TFE

Shutoff:

Class II, III & IV

Class IV, V & VI

Class IV & V

Flow Characteristics:

Linear

Quick Opening

Equal Percentage

Noise Abatement

Anti-Cavitation

Flow Direction: Normally Up, Normally Down

Features & Benefits

1. Anti-cavitation and noise abatement trim options

2. Optional NACE MR0175/ISO 15156-2009 compliance for sour service

3. Tight shutoff capability for enhanced performance and reliability

Product Name: Cage Guided Globe Control Valve

Key Features: Single-seated, Anti-Cavitation, Cage-guided

Sizes: 8×6 Inch, 10×8 Inch, 12×6 Inch, 12×8 Inch, 16×12 Inch, 20×16 Inch, 24×16 Inch, 24×20 Inch

Pressure: Class 150 LB - 900 LB

Body Materials: ASTM A352 LCC, ASTM A216 WCB, WCC, ASTM A217 WC9, C5, Monel, ASTM A351 CF8M SST

End Connections: Raised Face, Ring Type Joint and Welded Flanges

Trim Materials:

Standard Material: Stainless Steel SS 316

Optional Material: Alloy 6, Cobalt, Tungsten Carbide

Seats: Metal and TFE

Shutoff:

Class II, III & IV

Class IV, V & VI

Class IV & V

Flow Characteristics:

Linear

Quick Opening

Equal Percentage

Noise Abatement

Anti-Cavitation

Flow Direction: Normally Up, Normally Down

Features & Benefits

1. Anti-cavitation and noise abatement trim options

2. Optional NACE MR0175/ISO 15156-2009 compliance for sour service

3. Tight shutoff capability for enhanced performance and reliability

Comment Form