Sliding Diaphragm Gate Control Valve, 1/4-2 IN, Ductile Iron

Key Specifications / Features

Hits: 30

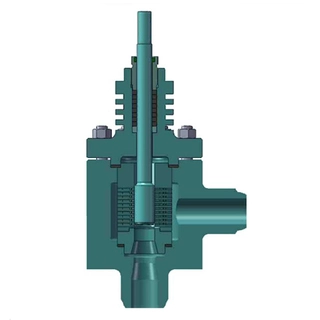

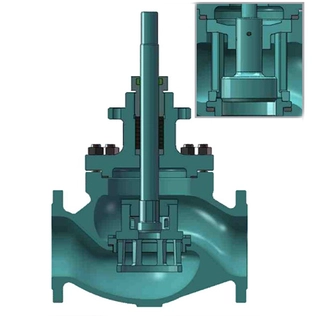

Introducing our line of pneumatically-operated diaphragm control valves, featuring multiple spring actuators and precision sliding gate seats for enhanced control and accuracy. Available in sizes from 1/4 inch to 2 inches (DN8-DN50) with PN10 and 150 LB pressure ratings, these valves are made from durable ductile iron, ideal for precise flow control in diverse industrial applications. Optionally, they can be equipped with side or top-mounted positioners to minimize hysteresis, ensuring the valve stem position aligns precisely with the control signal for optimal performance.

Request a quote

Tags

Detail Information

SPECIFICATIONS

Product Name: Diaphragm Gate Control Valve

Key Features: Multiple Spring Actuator, Pneumatically-operated, Tight Shutoff

Size Range: 1/4 Inch - 2 Inch, DN8-DN50

Pressure: PN10, Class 150 LB

Body Material: Cast Iron, Ductile Iron, Bronze, Carbon Steel (ASTM A216 WCB), Stainless Steel (ASTM A351 CF8M)

Seat Material: Jorcote on SST Standard

Trim Materials: SS 303 for CI and DI Body Valves, SS 316 for SS Body Nalves.

Yoke Material: Cast Iron

Actuator: Steel

Diaphragm: Buna-N (standard to 200°F/93°C)

Stem Packing: Spring-loaded Teflon (to 450°F/232°C), Graphite (to 1200°F/649°C)

Cv (Kv): up to 30 (up to 26)

Action: Direct (air signal closes valve), Reverse (air signal opens valve)

End Connections:

Threaded (NPT, BSPT, BSPP-through 2 Inch sizes/DN50)

ANSI Flanges (150#, 300#)

DIN Flanges (PN10/16, PN25/40)

Service: Steam, Water, Oil, Gas, Air and Chemicals

Features & Benefits:

1. The enclosed multi-spring actuator reduces deadband and allows field reversibility without special tools.

2. The compact, straightforward design facilitates quick installation and maintenance.

3. Stem packing offers four times the depth of stem travel, enhancing leak protection.

4. Sliding gate seats ensure straight-through flow, reducing turbulence and noise.

5. Short stroke ensures rapid response and precise regulation.

6. Easily interchangeable CV's.

7. Provides tight shutoff for reliable operation.

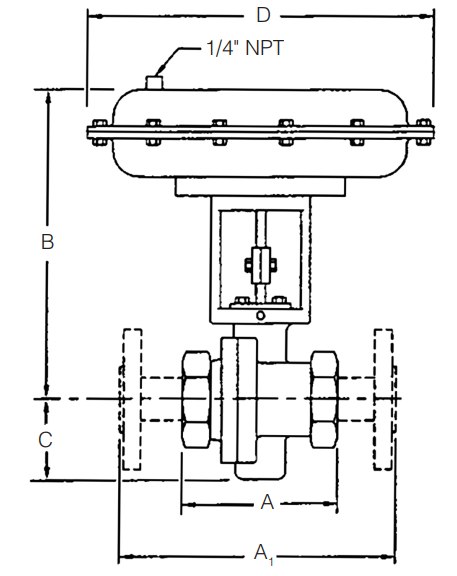

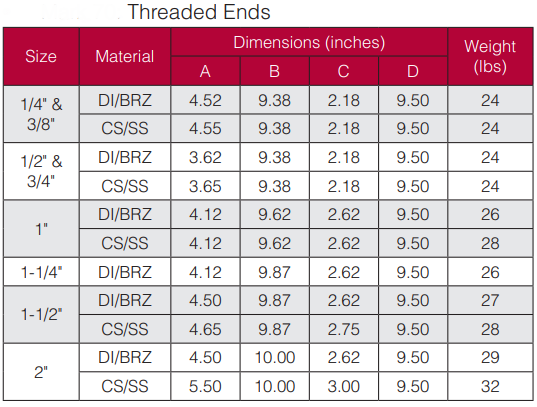

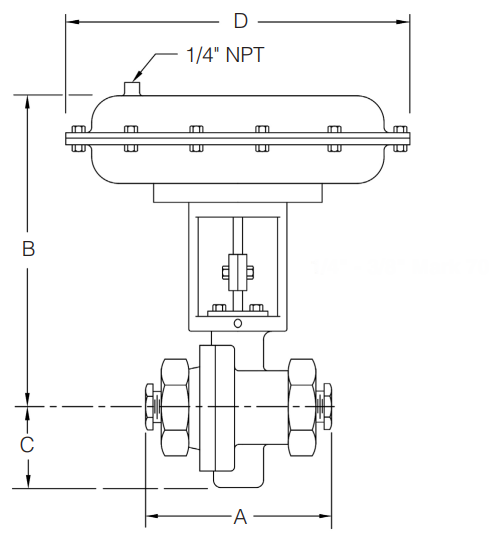

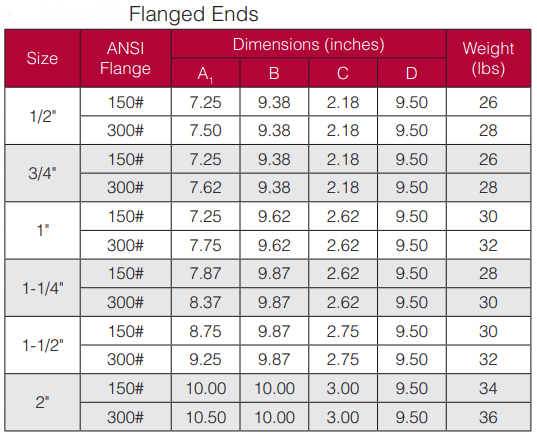

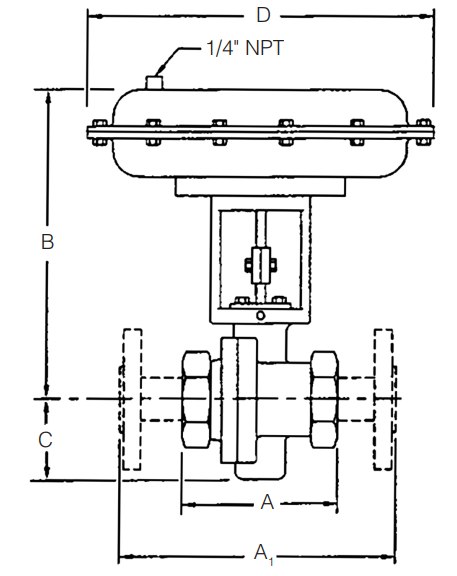

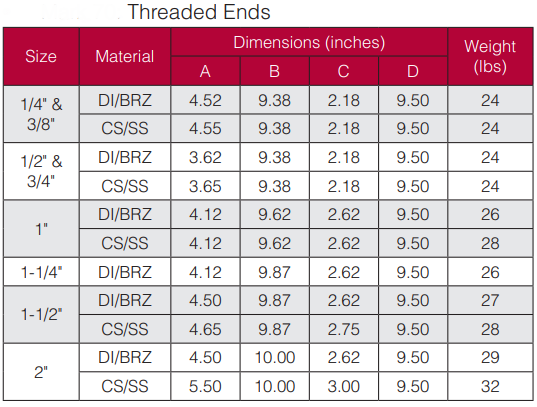

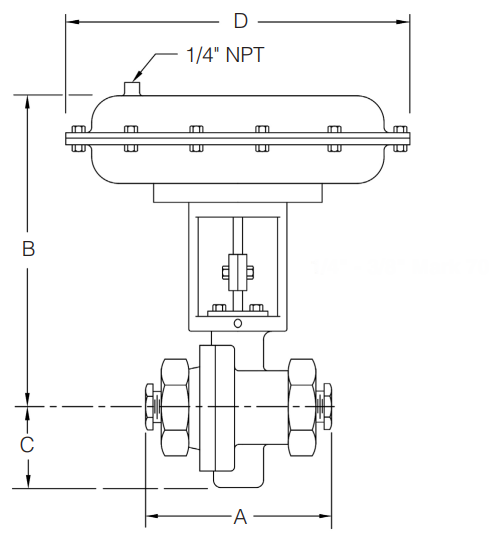

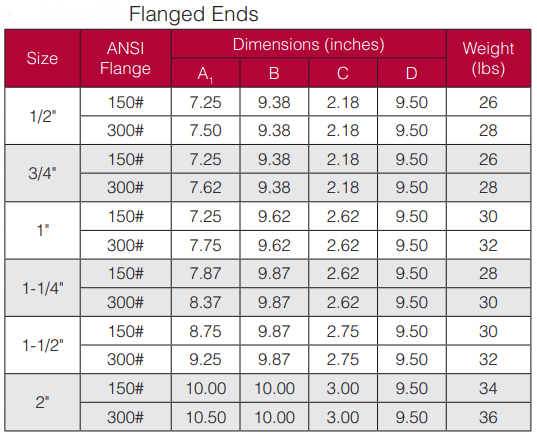

Dimensions:

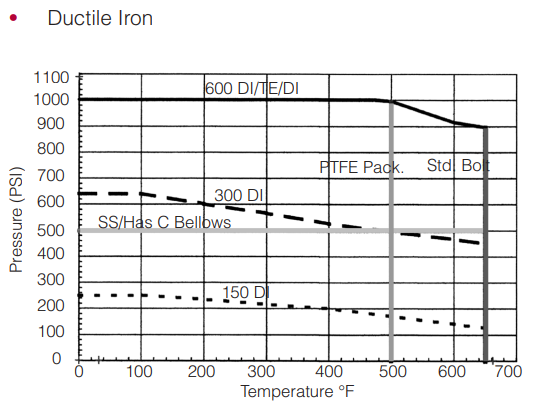

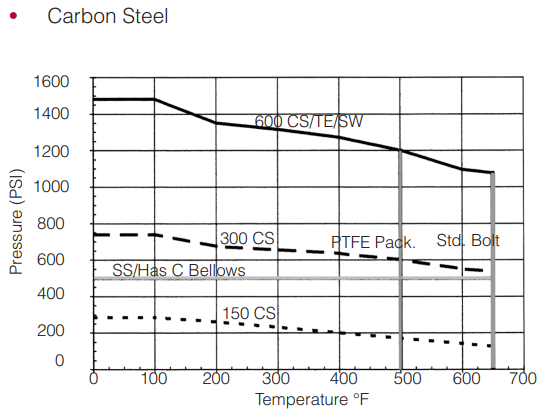

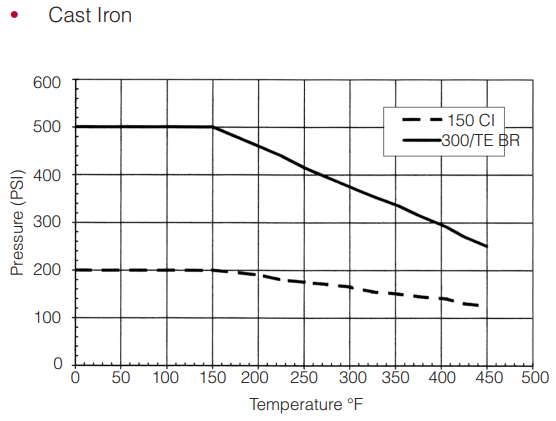

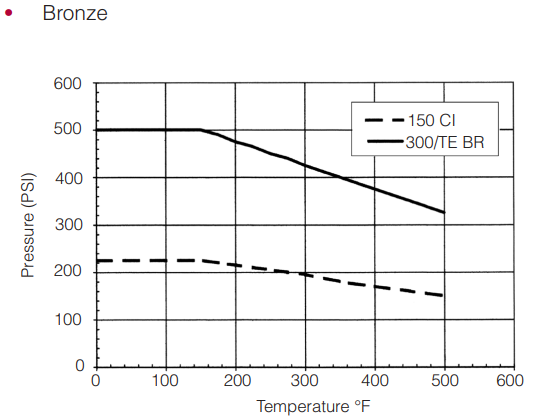

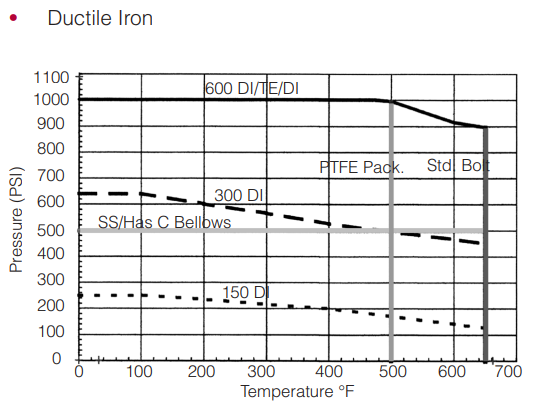

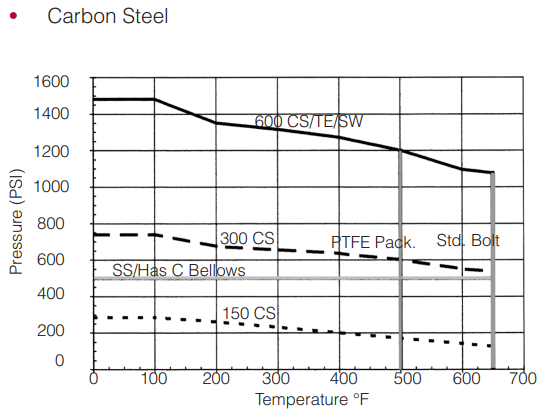

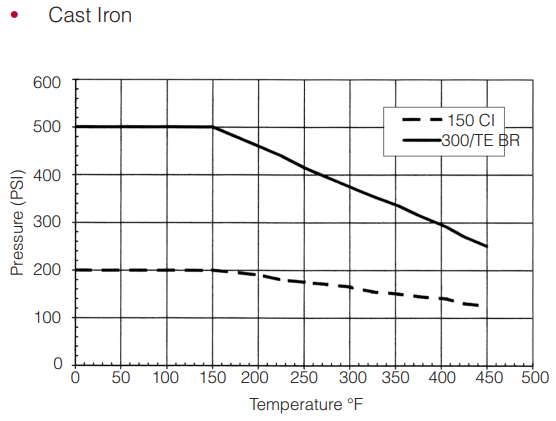

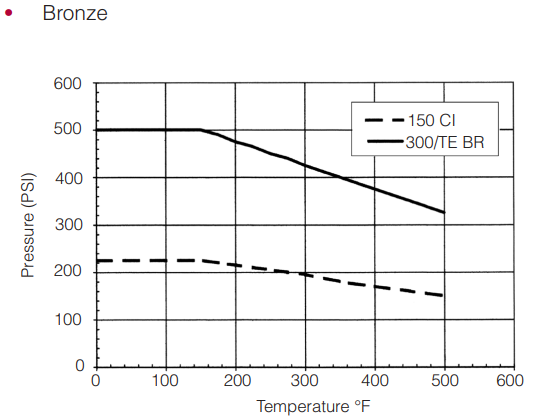

Pressure-Temperature Charts:

Product Name: Diaphragm Gate Control Valve

Key Features: Multiple Spring Actuator, Pneumatically-operated, Tight Shutoff

Size Range: 1/4 Inch - 2 Inch, DN8-DN50

Pressure: PN10, Class 150 LB

Body Material: Cast Iron, Ductile Iron, Bronze, Carbon Steel (ASTM A216 WCB), Stainless Steel (ASTM A351 CF8M)

Seat Material: Jorcote on SST Standard

Trim Materials: SS 303 for CI and DI Body Valves, SS 316 for SS Body Nalves.

Yoke Material: Cast Iron

Actuator: Steel

Diaphragm: Buna-N (standard to 200°F/93°C)

Stem Packing: Spring-loaded Teflon (to 450°F/232°C), Graphite (to 1200°F/649°C)

Cv (Kv): up to 30 (up to 26)

Action: Direct (air signal closes valve), Reverse (air signal opens valve)

End Connections:

Threaded (NPT, BSPT, BSPP-through 2 Inch sizes/DN50)

ANSI Flanges (150#, 300#)

DIN Flanges (PN10/16, PN25/40)

Service: Steam, Water, Oil, Gas, Air and Chemicals

Features & Benefits:

1. The enclosed multi-spring actuator reduces deadband and allows field reversibility without special tools.

2. The compact, straightforward design facilitates quick installation and maintenance.

3. Stem packing offers four times the depth of stem travel, enhancing leak protection.

4. Sliding gate seats ensure straight-through flow, reducing turbulence and noise.

5. Short stroke ensures rapid response and precise regulation.

6. Easily interchangeable CV's.

7. Provides tight shutoff for reliable operation.

Dimensions:

Pressure-Temperature Charts:

Comment Form