High Flow Sliding Gate Control Valve, DN15-DN50, CL 150 LB

Key Specifications / Features

Hits: 21

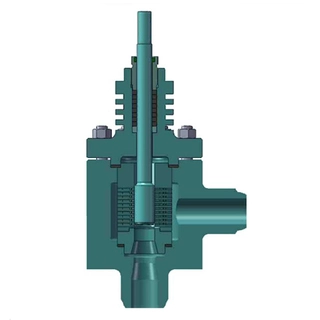

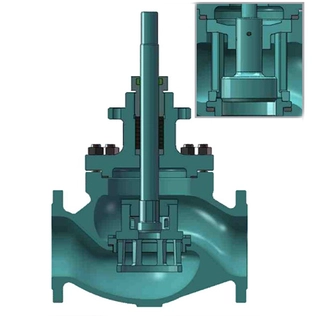

The high-flow sliding gate control valve offers increased Cv (Kv) values without needing a larger valve size, providing straight-through flow and easy maintenance. Available in sizes from 1/2 to 2 inches (DN15-DN50) with PN10 and Class 150 LB pressure ratings, these valves are constructed from durable ductile iron and carbon steel. Optional side or top-mounted positioners minimize hysteresis, ensuring the valve stem position is always directly proportional to the control valve command signal. Ideal for applications requiring precise flow control, this valve is a reliable and efficient solution.

Request a quote

Tags

Detail Information

SPECIFICATIONS

Product Name: Sliding Gate Control Valves

Key Features: High Flow and Super High Flow, Plug-Style Valve

Size Range: 1/2 Inch - 2 Inch, DN15-DN50

Pressure: PN10, Class 150 LB

Body Material: Cast Iron, Ductile Iron, Bronze, Carbon Steel (ASTM A216 WCB), Stainless Steel (ASTM A351 CF8M)

Seat Material: Jorcote on SST Standard

Trim Materials: SS 303 for CI and DI Body Valves, SS 316 for SS Body Nalves.

Yoke Material: Cast IronSeat Material: Jorcote on SST Standard

Actuator: Steel

Cv (Kv): up to 70 (up to 60,3)

Action: Direct (ATC) or Reverse (ATO)

Diaphragm: Buna-N (standard to 200°F/93°C)

Stem Packing: spring-loaded Teflon (to 450°F/232°C); Graphite (to 1200°F/649°C)

End Connections:

Threaded (NPT, BSPT, BSPP-through 2 Inch sizes/DN50)

ANSI Flanges (150#, 300#)

DIN Flanges (PN10/16, PN25/40)

Features & Benefits:

1. High Flow and Super High Flow: Ensures optimal performance in various applications.

2. Shorter Stroke: Faster response, extended packing, and seat life compared to globe or plug-style valves.

3. Enhanced Leak Protection: Stem packing is four times deeper than stem travel.

4. Compact and Lightweight: Smaller and lighter than globe-style valves for easier handling and installation.

5. Straight Through Flow: Reduces turbulence, erosion, and noise, promoting efficient operation.

6. Self-Cleaning Seats: Minimizes maintenance with fewer spare parts required and no gaskets or O-rings.

7. Ease of Maintenance: Features interchangeable seats and CVs for quick and simple servicing.

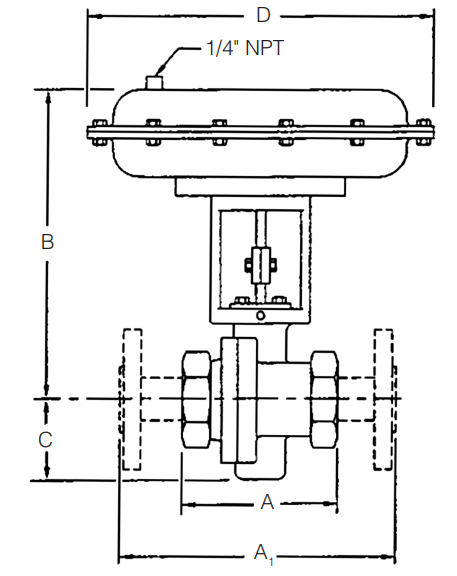

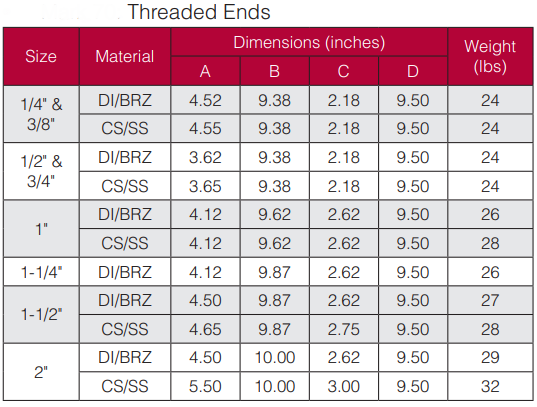

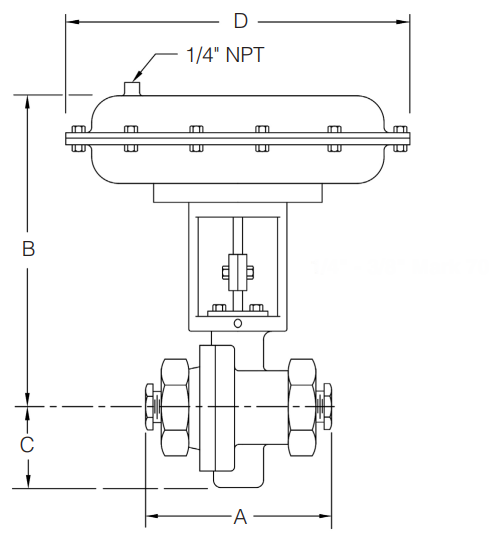

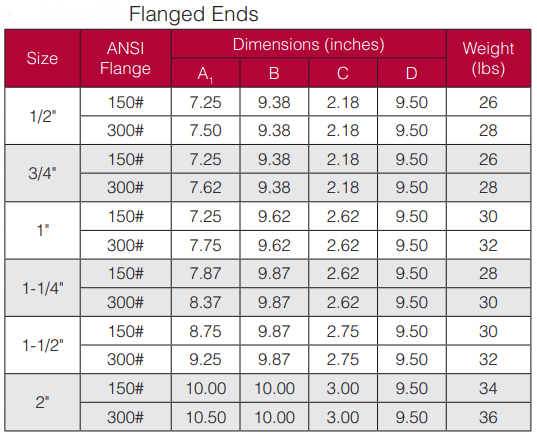

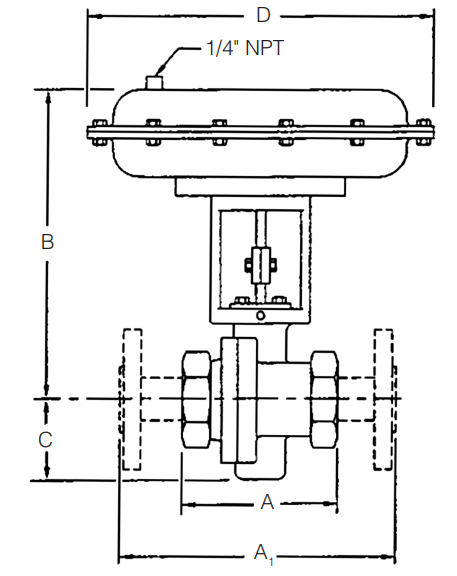

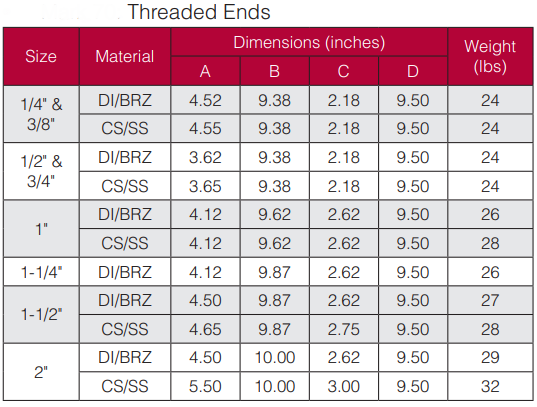

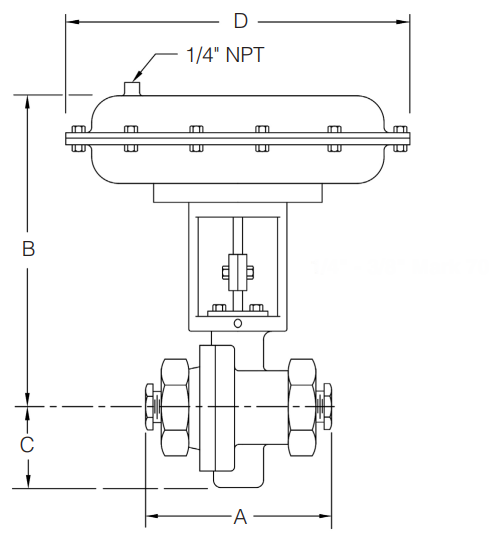

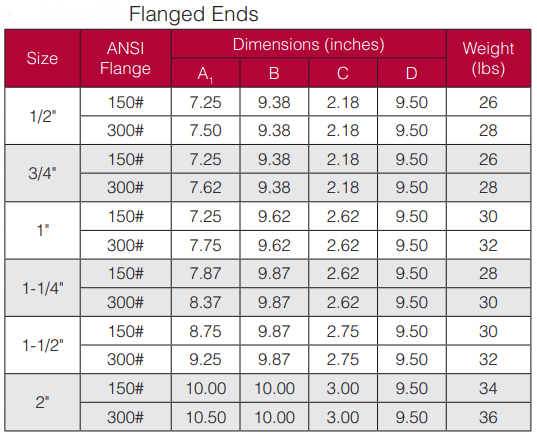

Dimensions:

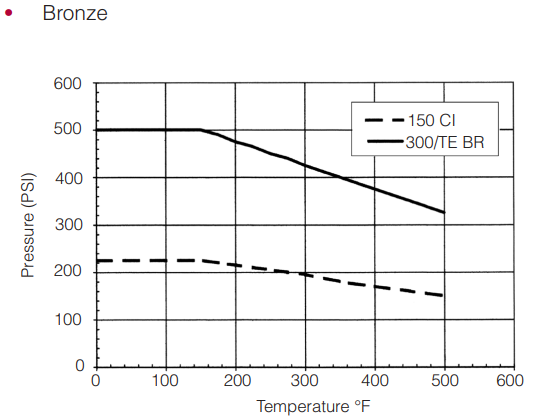

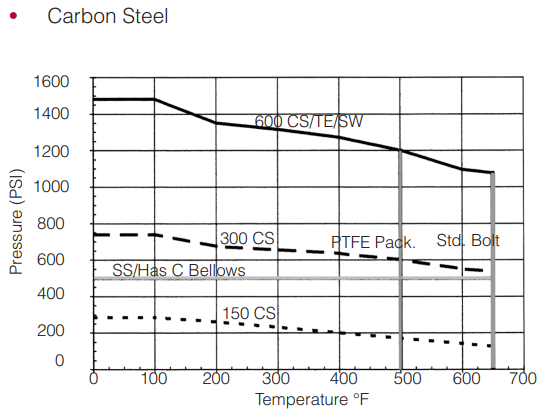

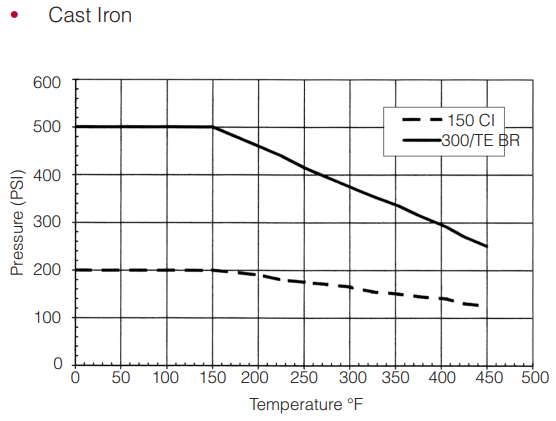

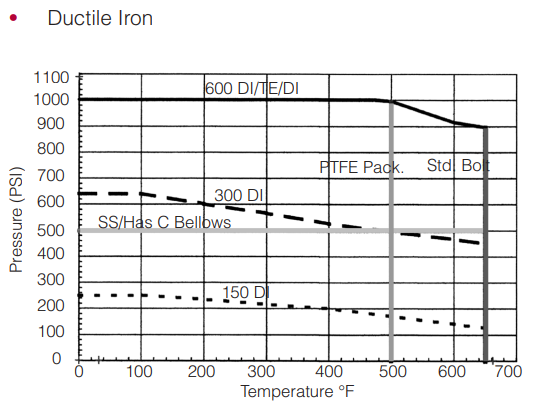

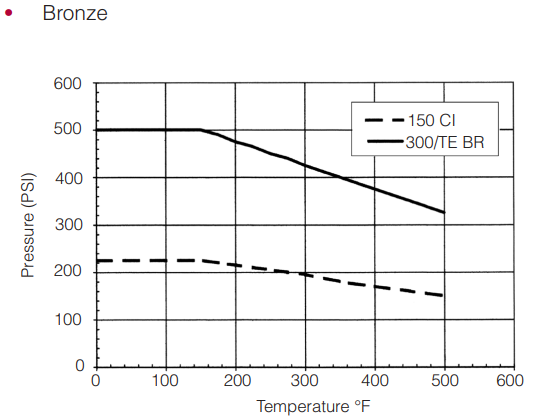

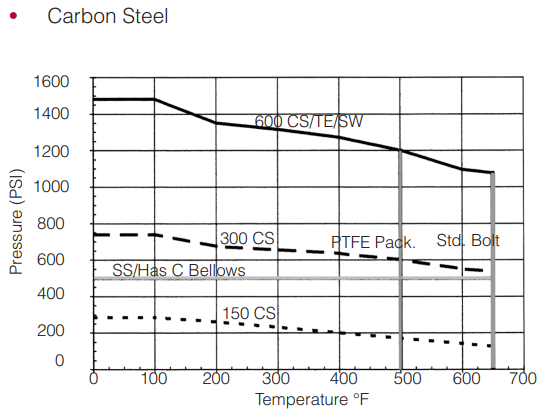

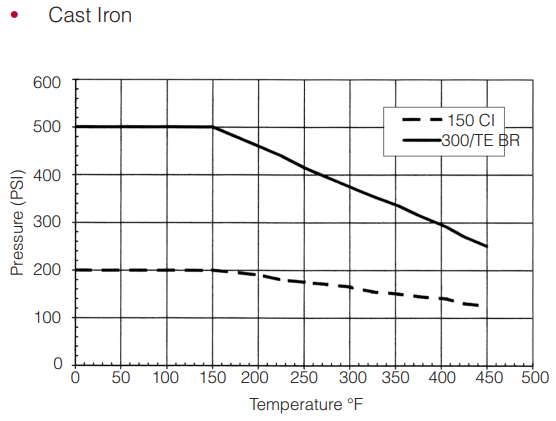

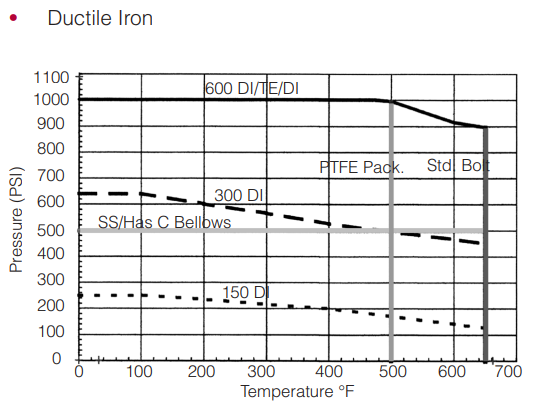

Pressure-Temperature Charts:

Product Name: Sliding Gate Control Valves

Key Features: High Flow and Super High Flow, Plug-Style Valve

Size Range: 1/2 Inch - 2 Inch, DN15-DN50

Pressure: PN10, Class 150 LB

Body Material: Cast Iron, Ductile Iron, Bronze, Carbon Steel (ASTM A216 WCB), Stainless Steel (ASTM A351 CF8M)

Seat Material: Jorcote on SST Standard

Trim Materials: SS 303 for CI and DI Body Valves, SS 316 for SS Body Nalves.

Yoke Material: Cast IronSeat Material: Jorcote on SST Standard

Actuator: Steel

Cv (Kv): up to 70 (up to 60,3)

Action: Direct (ATC) or Reverse (ATO)

Diaphragm: Buna-N (standard to 200°F/93°C)

Stem Packing: spring-loaded Teflon (to 450°F/232°C); Graphite (to 1200°F/649°C)

End Connections:

Threaded (NPT, BSPT, BSPP-through 2 Inch sizes/DN50)

ANSI Flanges (150#, 300#)

DIN Flanges (PN10/16, PN25/40)

Features & Benefits:

1. High Flow and Super High Flow: Ensures optimal performance in various applications.

2. Shorter Stroke: Faster response, extended packing, and seat life compared to globe or plug-style valves.

3. Enhanced Leak Protection: Stem packing is four times deeper than stem travel.

4. Compact and Lightweight: Smaller and lighter than globe-style valves for easier handling and installation.

5. Straight Through Flow: Reduces turbulence, erosion, and noise, promoting efficient operation.

6. Self-Cleaning Seats: Minimizes maintenance with fewer spare parts required and no gaskets or O-rings.

7. Ease of Maintenance: Features interchangeable seats and CVs for quick and simple servicing.

Dimensions:

Pressure-Temperature Charts:

Comment Form