Non-Lubricating Globe Control Valve, 1-4 IN, 150-600 LB, WCB

Key Specifications / Features

Hits: 18

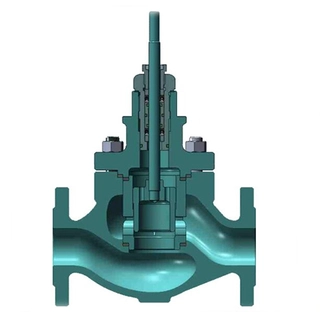

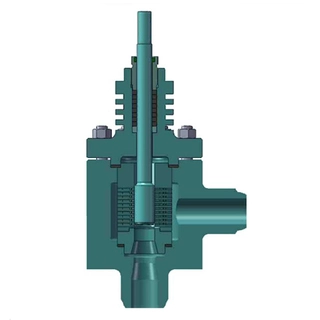

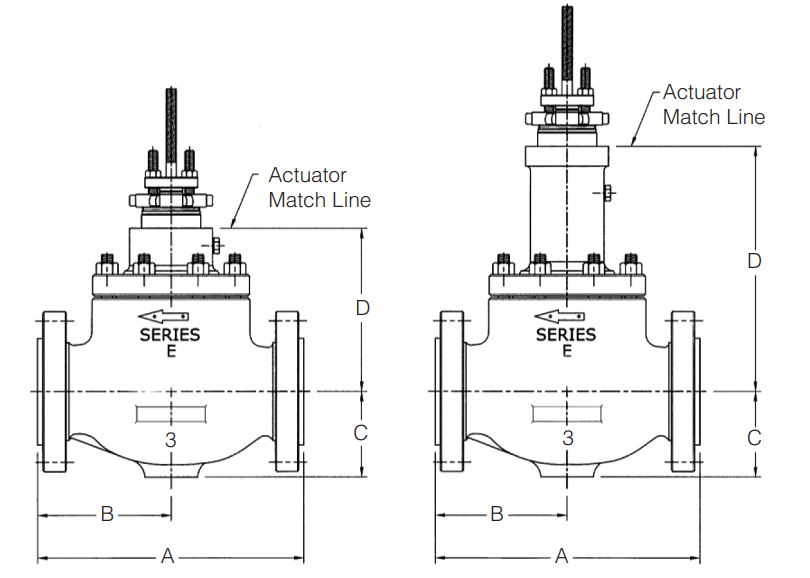

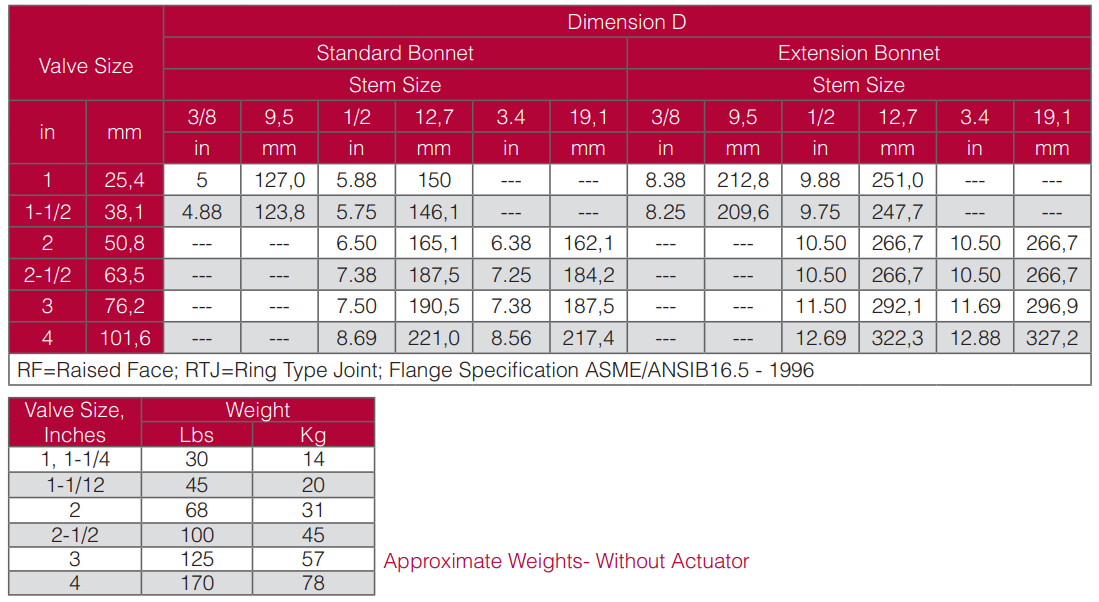

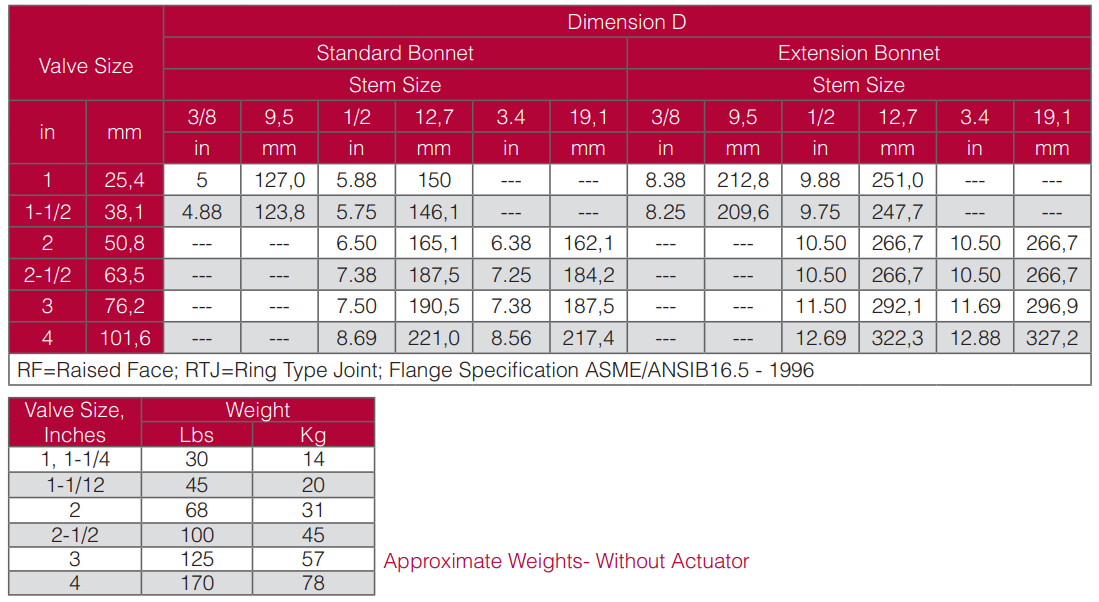

This globe control valve features integral end connections, post guiding, and a quick-change trim design. Ideal for chemical and hydrocarbon processing, it excels in handling viscous, non-lubricating, and other challenging fluids. The valve accommodates various end connection styles, including flanged Class 150, 300, and 600 raised face, ring-type joint, or flat face, adhering to ASME B16.5 standards. Additionally, screwed connections meet Class 600 specifications as per the latest ASME B16.34 edition, ensuring versatile application and robust performance.

Request a quote

Tags

Detail Information

SPECIFICATIONS

Product Name: Cage-guided Globe Control Valves

Key Features: Cage-guided, Non-lubricating, Globe Style

Size Range: 1 Inch - 4 Inch, DN25-DN100

Pressure: Class 150 LB - 600 LB

Body Materials: ASTM A352 LCC, ASTM A216 WCB, WCC, ASTM A217 WC9, C5, Monel, ASTM A351 CF8M SST.

Trim Materials:

Standard Material: Stainless Steel, SS 316.

Optional Material: Alloy 6, Cobalt, Tungsten Carbide.

Seats: Metal and TFE

Shutoff: Class IV & V

Flow Characteristics:

Linear

Quick Opening

Equal Percentage

Noise Abatement

Anti-Cavitation

Flow Direction: Flow Up Through the Seat Ring.

Features & Benefits

1. Offers characterized flow options such as equal percentage, linear, and quick opening.

2. Available in various body and trim materials to suit diverse applications.

3. Features quick-change trim for easy maintenance.

4. Optional NACE MRO 175 / ISO 15156-2009 for sour service capability.

5. Ensures tight shutoff for reliable operation.

Product Name: Cage-guided Globe Control Valves

Key Features: Cage-guided, Non-lubricating, Globe Style

Size Range: 1 Inch - 4 Inch, DN25-DN100

Pressure: Class 150 LB - 600 LB

Body Materials: ASTM A352 LCC, ASTM A216 WCB, WCC, ASTM A217 WC9, C5, Monel, ASTM A351 CF8M SST.

Trim Materials:

Standard Material: Stainless Steel, SS 316.

Optional Material: Alloy 6, Cobalt, Tungsten Carbide.

Seats: Metal and TFE

Shutoff: Class IV & V

Flow Characteristics:

Linear

Quick Opening

Equal Percentage

Noise Abatement

Anti-Cavitation

Flow Direction: Flow Up Through the Seat Ring.

Features & Benefits

1. Offers characterized flow options such as equal percentage, linear, and quick opening.

2. Available in various body and trim materials to suit diverse applications.

3. Features quick-change trim for easy maintenance.

4. Optional NACE MRO 175 / ISO 15156-2009 for sour service capability.

5. Ensures tight shutoff for reliable operation.

Comment Form