Pneumatic Mixing Globe Control Valve, 3/4-14 Inch, WCB, WC6

Key Specifications / Features

Hits: 13

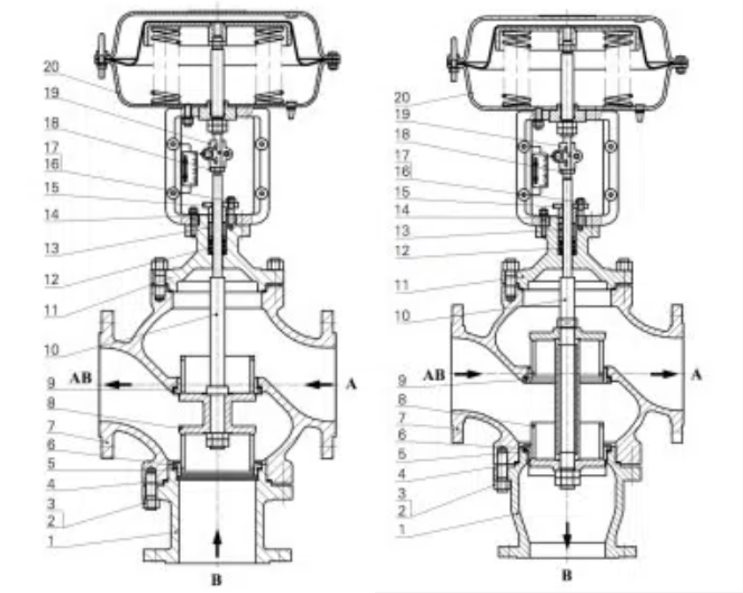

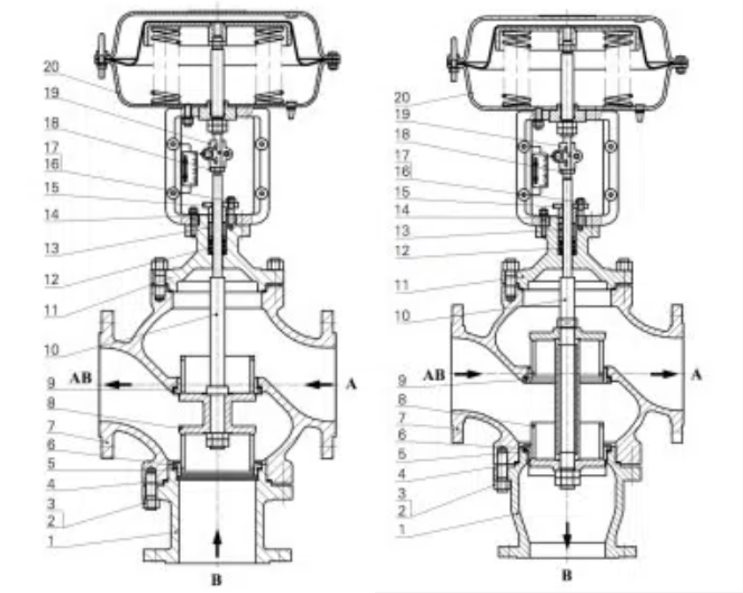

The Pneumatic Mixing Globe Control Valve operates with a plug structure designed for flow-to-open action. In mixing service control, it features two input ports and one outlet port, while in diverting service control, it has one inlet port and two outlet ports. As it functions in both opening and closing simultaneously, it doesn't rely on separate air-to-open or air-to-close mechanisms. In Direct Action Mixing Service, air failure leads to vertical flow (B → AB), whereas in Reverse Action Mixing Service, it results in horizontal flow (A → AB). Similarly, in Direct Action Diverting Service, air failure causes horizontal flow (AB → A), while in Reverse Action Diverting Service, it leads to vertical flow (AB → B).

Request a quote

Tags

Detail Information

SPECIFICATIONS

Product Name: Pneumatic Mixing Globe Control Valve

Size Range: 3/4 - 14 Inch, DN20-DN350

Materials: ASTM A216 WCB, WC6, ASTM A352 LCB, ASTM A351 CF8, CF8M, CF3M, CF3

Key Features: Pneumatic Mixing Type, Three Way, Carbon Steel

Pressure rating: ANSI Class 125 LB, 150 LB, 300 LB, 600 LB, JIS 10K, 16K, 20K, 30K, 40K, PN16, PN40, PN64, PN100

Temperature Range: -196 to +450°C

End connection:

Flanged End: FF(Flat Face), RF(Raised Face), RJ(Ring Joint), LG(Large Male)

Welded End: SW(Socket Weld), BW(Butt Weld)

Threaded End: Rc(British Standard Pipe Taper)

Bonnet:

Plain bonnet (-17 to 230°C)

Extension bonnet (-60 to -29 °C or over 230°C)

Product Name: Pneumatic Mixing Globe Control Valve

Size Range: 3/4 - 14 Inch, DN20-DN350

Materials: ASTM A216 WCB, WC6, ASTM A352 LCB, ASTM A351 CF8, CF8M, CF3M, CF3

Key Features: Pneumatic Mixing Type, Three Way, Carbon Steel

Pressure rating: ANSI Class 125 LB, 150 LB, 300 LB, 600 LB, JIS 10K, 16K, 20K, 30K, 40K, PN16, PN40, PN64, PN100

Temperature Range: -196 to +450°C

End connection:

Flanged End: FF(Flat Face), RF(Raised Face), RJ(Ring Joint), LG(Large Male)

Welded End: SW(Socket Weld), BW(Butt Weld)

Threaded End: Rc(British Standard Pipe Taper)

Bonnet:

Plain bonnet (-17 to 230°C)

Extension bonnet (-60 to -29 °C or over 230°C)

Three-ways Mixing Type Control Valves

1. Connect Pipe

2. Double-screw Bolt

3. Hexagon Nut

4. Sealing

5. Gasket

6. Lower Bonnet

7. Body

8. Plug

9. Upper Seat

10. Stem

11. Bonnet

12. Packing Spring

13&14. Nuts&Bolts

15. Spring Plate

16&17. Studs&Nuts

18. Locknut

19. Stem Connector

20. Actuator

2. Double-screw Bolt

3. Hexagon Nut

4. Sealing

5. Gasket

6. Lower Bonnet

7. Body

8. Plug

9. Upper Seat

10. Stem

11. Bonnet

12. Packing Spring

13&14. Nuts&Bolts

15. Spring Plate

16&17. Studs&Nuts

18. Locknut

19. Stem Connector

20. Actuator

Comment Form