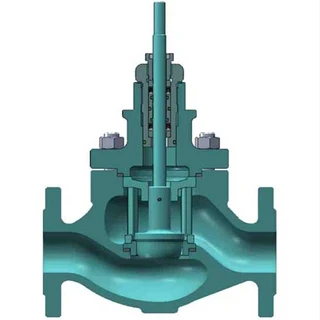

Top Guided Globe Control Valve, 3-way, 1-12 Inch, A216 WCB

Key Specifications / Features

Hits: 9

The Globe 3-Way Mixing and Diverting Valve is designed for versatile fluid control in sizes ranging from 1 inch to 12 inches (DN25-DN300). Featuring a single-seated top guide and bolted bonnet, this valve supports pressure classes from 150 LB to 600 LB (PN20-PN100). Constructed from ASTM A216 WCB material, it ensures durability and reliability. The valve offers various flow characteristics, including linear, equal percentage, and modified percentage, making it suitable for a wide range of applications.

Request a quote

Tags

Detail Information

SPECIFICATIONS

Product Name: Top Guided Globe Control Valve

Key Features: Mixing and Diverting Valve, Single seated, Top Guided, Three way

Sizes: 1 Inch - 12 Inch, DN25-DN300

Pressure Rating: Class 150 LB - 600 LB, PN20-PN100

Body Material: ASTM A216 WCB, SS 304, SS 306, Alloys

TRIM Materials: SS 304, SS 306, Alloys

Seat Materials: Soft, Metal

CV Ratio: 50:1

Flow characteristics: linear, equal percentage and modified percentage

End Connection: Flanged, Butt weld, Socket weld

TEMPERATURE RANGE: -22°F to +1049°F

Applications:

Wide range of process applications

Diverting, mixing and combining in a variety of steam, liquid and gases

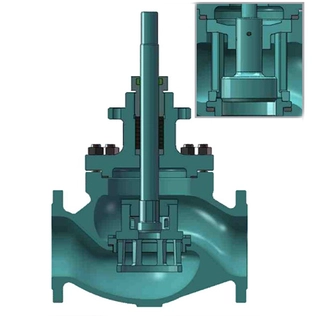

Features and Benefits:

Available in various construction designs with different end styles and configurations.

Excellent shutoff capabilities: Class V (metal seat) and Class VI (soft seat).

Characterized trim options in equal percentage and linear profiles.

All trim components are easily removable for straightforward maintenance.

High integrity guiding system for reliable performance.

Low emission packing options available.

Stable flow control with high rangeability.

Top guided control with erosion-resistant trims.

Precision Cv flow passages ensure accurate capacity.

Rugged upper guide and seat ring guide for enhanced durability.

Product Name: Top Guided Globe Control Valve

Key Features: Mixing and Diverting Valve, Single seated, Top Guided, Three way

Sizes: 1 Inch - 12 Inch, DN25-DN300

Pressure Rating: Class 150 LB - 600 LB, PN20-PN100

Body Material: ASTM A216 WCB, SS 304, SS 306, Alloys

TRIM Materials: SS 304, SS 306, Alloys

Seat Materials: Soft, Metal

CV Ratio: 50:1

Flow characteristics: linear, equal percentage and modified percentage

End Connection: Flanged, Butt weld, Socket weld

TEMPERATURE RANGE: -22°F to +1049°F

Applications:

Wide range of process applications

Diverting, mixing and combining in a variety of steam, liquid and gases

Features and Benefits:

Available in various construction designs with different end styles and configurations.

Excellent shutoff capabilities: Class V (metal seat) and Class VI (soft seat).

Characterized trim options in equal percentage and linear profiles.

All trim components are easily removable for straightforward maintenance.

High integrity guiding system for reliable performance.

Low emission packing options available.

Stable flow control with high rangeability.

Top guided control with erosion-resistant trims.

Precision Cv flow passages ensure accurate capacity.

Rugged upper guide and seat ring guide for enhanced durability.

Comment Form