Segmented Ball Control Valves, 1-20 IN, PN10-PN63, A216 WCB

Key Specifications / Features

Hits: 19

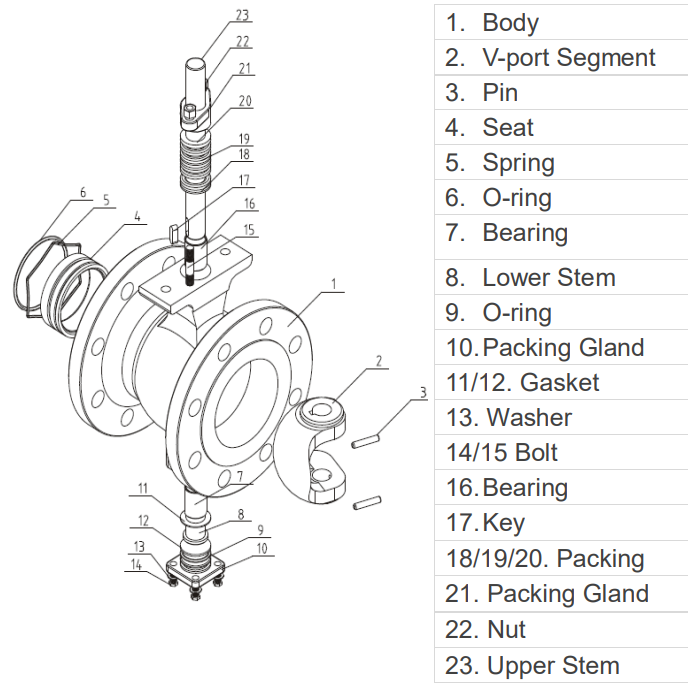

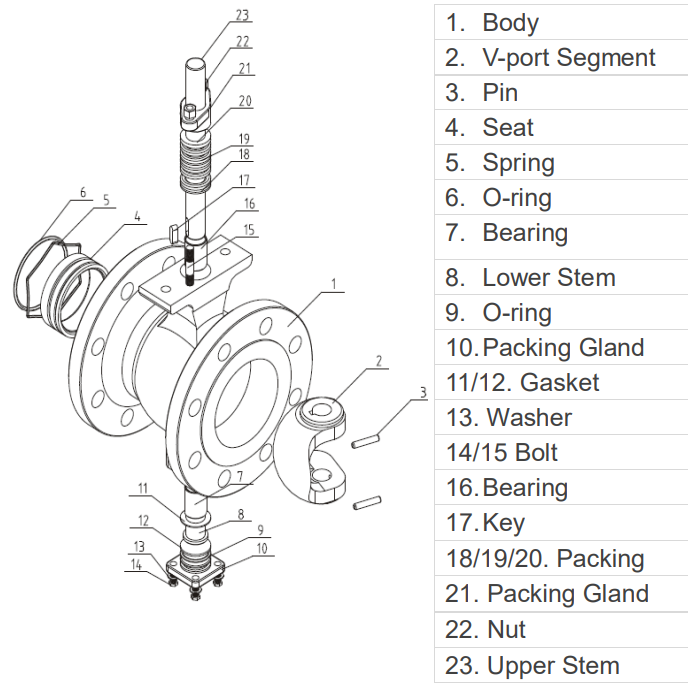

Our Segmented Ball Control Valves, manufactured in China, feature a robust single-piece design crafted from ASTM A216 WCB material. Available in sizes ranging from 1 to 20 inches, with pressure ratings from PN10 to PN63 (Class 150-600 LB), these valves are ideal for precise flow control and shut-off operations. The V-port design includes a notched port on the segment ball, enhancing shear stress capability for cutting through media containing fibers and particles effectively. This makes our v-port segment valve particularly suited for pulp and paper processing applications or similar flows with challenging media compositions. Count on our Segmented Ball Control Valves for reliable performance and durability in demanding industrial environments.

Request a quote

Tags

Detail Information

Product Introduction

Product Name: Segmented Ball Control Valve

Size Range: 1-20 Inch, DN25-DN500

Pressure Rating: PN10-PN64, Class 150 LB - 600 LB

Temperature Range: Metal Seat -29°C to +450°C, Resilient Seat -29°C to +150°C

Seal Tightness: Metal Seat Class IV, Resilient Seat Class VI

Body Material: ASTM A216 WCB, ASTM A351 CF8, CF8M, Carbon Steel, Stainless Steel, Special Alloy.

Ball/Stem Material: Stainless Steel, Special Alloys.

Seat Material: Stainless Steel+STL, PCTFE, PEEK (Flange), Stainless Steel+STL (Wafer)

Face to Face: ISA S75.04, IEC/DIN 534-3-2 (Flange)

Flange Standard: GB/T 9113.1, JB/T 79.1, HG 20592, ASME B 16.34, ISO 7005 (Other drilling on request).

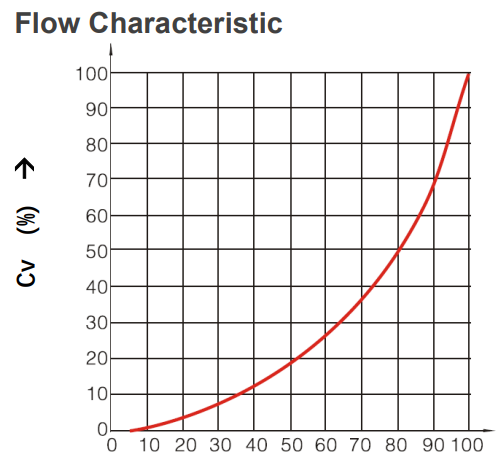

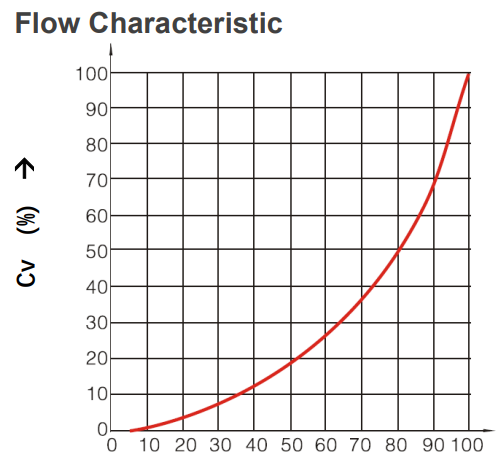

Flow Characteristic: Equal Percentage

End Connection: Flange

Applications: Pulp & Paper, Water Treatment, Food & Beverage, Fine Chemical, Power Plant, Steel Industry

Features:

1. Integral body design ensures greater rigidity against fluctuating pipe loads.

2. Eliminates leak paths common in two-piece body designs.

3. Available in both wafer and flange connections.

4. V-notch ball design delivers strong cutting stress and tight sealing.

Product Name: Segmented Ball Control Valve

Size Range: 1-20 Inch, DN25-DN500

Pressure Rating: PN10-PN64, Class 150 LB - 600 LB

Temperature Range: Metal Seat -29°C to +450°C, Resilient Seat -29°C to +150°C

Seal Tightness: Metal Seat Class IV, Resilient Seat Class VI

Body Material: ASTM A216 WCB, ASTM A351 CF8, CF8M, Carbon Steel, Stainless Steel, Special Alloy.

Ball/Stem Material: Stainless Steel, Special Alloys.

Seat Material: Stainless Steel+STL, PCTFE, PEEK (Flange), Stainless Steel+STL (Wafer)

Face to Face: ISA S75.04, IEC/DIN 534-3-2 (Flange)

Flange Standard: GB/T 9113.1, JB/T 79.1, HG 20592, ASME B 16.34, ISO 7005 (Other drilling on request).

Flow Characteristic: Equal Percentage

End Connection: Flange

Applications: Pulp & Paper, Water Treatment, Food & Beverage, Fine Chemical, Power Plant, Steel Industry

Features:

1. Integral body design ensures greater rigidity against fluctuating pipe loads.

2. Eliminates leak paths common in two-piece body designs.

3. Available in both wafer and flange connections.

4. V-notch ball design delivers strong cutting stress and tight sealing.

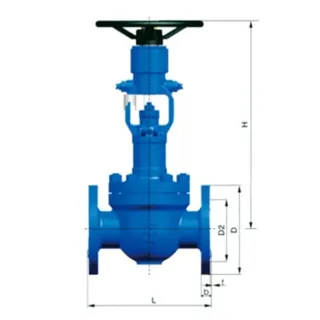

Drawing for Segmented Ball Control Valves

Flow Characteristic

Comment Form