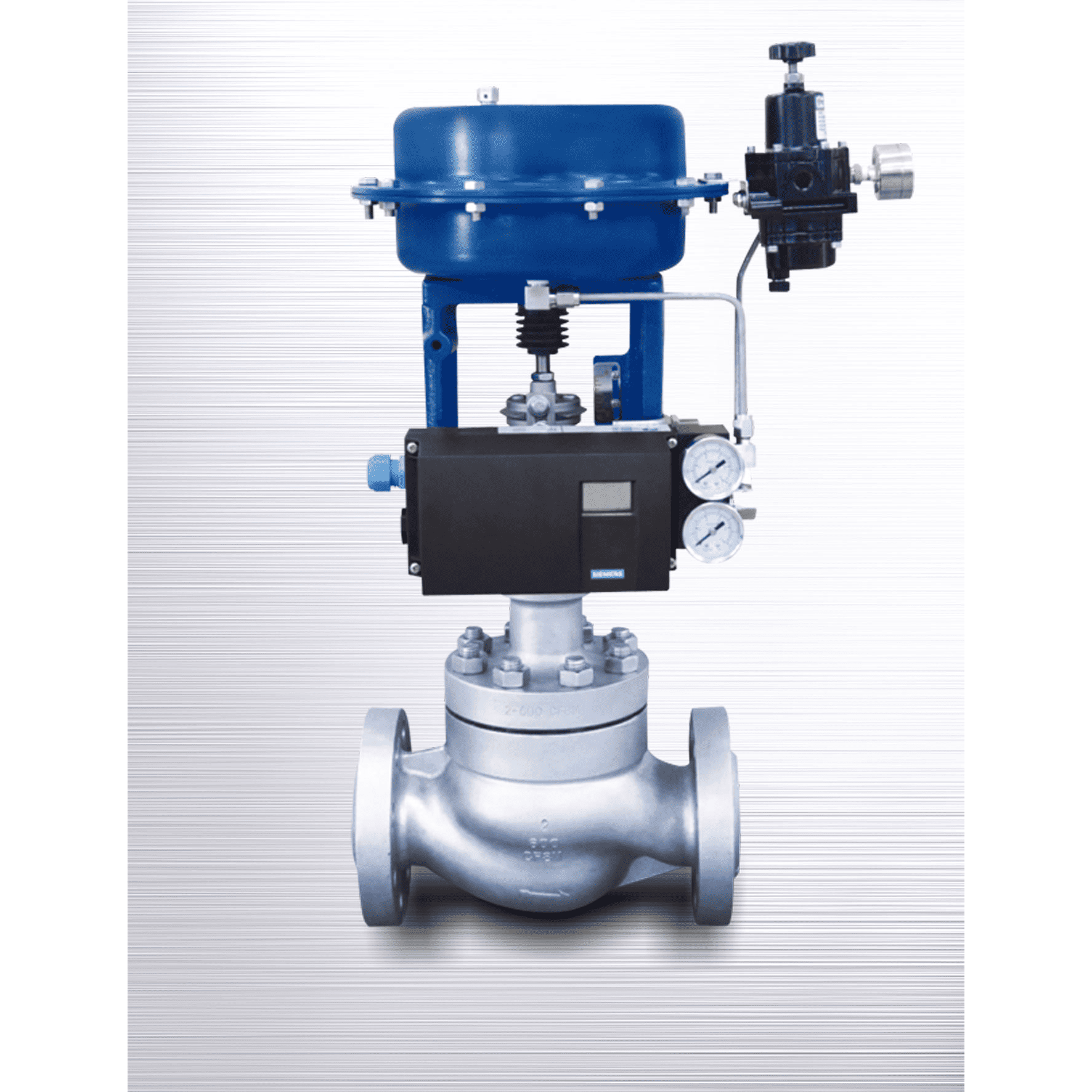

In the diverse world of industrial fluid control, selecting the right control valve is vital for ensuring operational efficiency, process stability, and safety. Among the many designs available today, the cage guided double seated control valve stands out as a robust solution for applications that demand precise flow control under moderate pressure and temperature conditions. With its unique double-seat structure and cage-guided trim, this valve delivers balanced performance, reduced actuator thrust requirements, and easy maintenance, making it a go-to choice for industries such as petrochemicals, power generation, chemical processing, and general industrial pipelines.

Unlike single-seat control valves, which rely on a single sealing surface, the double seated control valve employs two sealing seats working together to balance the fluid forces acting on the valve plug. This design drastically minimizes the thrust required to open and close the valve, even in systems with relatively high differential pressure. The cage guiding further enhances stability by providing accurate alignment and support to the plug, resulting in improved flow characteristics and dynamic performance.

In this comprehensive article, we will explore how cage guided double seated control valves work, what makes them so effective in specific applications, and how their design benefits both operators and maintenance personnel alike.

At the heart of the cage guided double seated control valve is its innovative pressure-balanced plug and dual-seat structure. The valve body houses two valve seats — one at the upper section and one at the lower. Sandwiched between these seats is a plug or valve core, which moves vertically along the valve stem. This plug is precisely machined to ensure that its two sealing surfaces mate perfectly with the corresponding seats.

When a control signal is sent to the actuator, it drives the plug to move up or down inside the cage. This movement changes the size of the flow passages between the seats, effectively regulating the flow rate and controlling the downstream pressure. The cage, a perforated or slotted cylinder surrounding the plug, acts as a guide to maintain concentric movement and dampen turbulence, enhancing the valve’s overall dynamic stability.

One of the greatest advantages of this double-seated configuration is the self-balancing effect it produces. Because fluid forces act on both the upper and lower surfaces of the plug, they counteract each other, significantly reducing the net force acting along the plug’s axis. This means the actuator does not need to generate as much thrust as it would in a single-seat design, allowing the use of smaller, more cost-effective actuators while still managing high-pressure drops across the valve.

The hallmark feature of this valve is its dual-seat configuration. It enables a balanced design that can handle higher pressure drops with lower actuator force requirements. The double sealing surfaces also improve the valve’s ability to handle flow in both directions if necessary.

The guiding cage plays a vital role in stabilizing the plug during operation. It reduces vibration and side loading, ensuring that the plug moves smoothly along its axis. The cage also contributes to noise attenuation and flow conditioning, which are essential for maintaining stable process conditions.

By distributing fluid pressure equally on opposite sides of the plug, the valve achieves a balanced structure that minimizes unbalanced forces. This reduces wear on internal components and prolongs the valve’s service life.

The valve offers flexibility in its sealing arrangement. The primary sealing ring is typically metal, providing durability for standard applications. A secondary sealing ring can be selected as either metal or soft (e.g., PTFE or elastomer), depending on the desired leakage class and temperature range. A soft seal ensures better shutoff performance when tight leakage control is required.

Due to its balanced design and robust guiding, the valve can withstand higher differential pressures without the risk of seat leakage or plug instability.

Many cage guided double seated control valves are designed with quick trim replacement features, allowing internal components to be serviced or replaced without removing the valve body from the pipeline. This minimizes downtime and reduces maintenance costs.

While these valves are not typically used in ultra-high-pressure or severe service applications, they excel in medium- and low-pressure scenarios where balanced operation is needed.

The balanced plug design translates to reduced actuator size and power consumption, saving operational costs in the long run.

Cage guiding and balanced flow forces provide excellent dynamic stability, even when process conditions fluctuate or differential pressures are high. This stability helps maintain consistent process variables, reducing the risk of surges or flow oscillations.

The cage design contributes to noise attenuation by controlling flow paths and dissipating energy within the valve. This is especially valuable in steam and gas applications where flow noise can be significant.

Lower thrust requirements and minimized wear on the plug and seats extend the valve’s lifespan. Users benefit from reduced maintenance frequency and longer intervals between overhauls.

Because the cage and plug assemblies are modular, maintenance personnel can access and replace trims quickly and easily, ensuring minimal disruption to operations.

Cage guided double seated control valves are widely employed in various industries and processes, such as:

Petrochemical Plants: For flow control in cooling water systems, steam lines, or other non-critical leakage service conditions.

Power Generation: In feedwater or low-pressure steam circuits where balanced flow control and reliable operation are critical.

Chemical Processing: For general service pipelines where moderate shutoff requirements are acceptable.

Pulp and Paper Industry: Managing process fluids such as process water or chemical additives.

General Industrial Use: Wherever stable flow control is required under moderate differential pressures and temperatures.

These valves are particularly suitable where high flow capacities and compact actuator sizes are desired.

When selecting or specifying a cage guided double seated control valve, several factors should be evaluated to ensure optimal performance and cost-effectiveness:

Since double seated valves typically cannot achieve the tightest shutoff (compared to single-seat or soft-seated designs), they are best suited for applications with moderate shutoff demands. If zero leakage is critical, a single-seat or triple-offset valve might be more appropriate.

Body and trim materials should be compatible with the process fluid, pressure, and temperature conditions. Common materials include carbon steel, stainless steel, and special alloys for corrosive or erosive media.

Consider whether a soft or metal secondary seal is needed based on the desired leakage performance and operating temperature range. Soft seals provide tighter shutoff but may not handle extreme temperatures as well as metal seals.

Because the balanced design reduces required thrust, actuators can often be smaller than those used with unbalanced valves. However, proper sizing is still essential to ensure responsive and reliable valve performance under all conditions.

For applications involving gases or steam at high velocities, additional noise-reducing features such as special cage perforations or multi-stage trims may be specified.

Proper installation and regular maintenance are essential to maximize the service life of cage guided double seated control valves:

Always install the valve as per manufacturer guidelines, ensuring that flow direction matches the design.

Periodically check for signs of seat wear, plug erosion, or leakage. Early detection of wear can prevent unplanned shutdowns.

One of the greatest advantages of this valve type is the ability to replace trims without removing the entire valve from the pipeline. Operators should be trained to perform safe and efficient trim maintenance.

Ensure that the actuator is correctly calibrated for the required control signal range and that positioners, if used, are properly tuned.

Before installation, store valves in a clean, dry area to prevent corrosion. Avoid impacts or mechanical stress that could affect the alignment of the cage and plug assembly.

As industries strive for higher efficiency and lower emissions, control valve technologies continue to evolve. Manufacturers are developing advanced materials, smart positioners, and digital diagnostic tools that integrate seamlessly with cage guided double seated control valves.

Remote monitoring and predictive maintenance technologies are gaining traction, enabling operators to track valve performance metrics in real-time. By analyzing data such as actuator cycles, plug position, and temperature, plants can optimize maintenance schedules and avoid costly unexpected failures.

Additionally, modern designs are focusing on noise reduction and energy-saving features, further improving the environmental sustainability of fluid control systems.

The cage guided double seated control valve remains a reliable and versatile solution for industrial flow control applications where moderate shutoff performance, balanced operation, and stable control are required. With its ingenious double-seat configuration, robust cage guiding, and pressure-balanced plug, this valve type minimizes actuator force requirements and ensures smooth, stable flow regulation under varying process conditions.

While it may not be suited for ultra-tight shutoff requirements or severe service conditions, its advantages in terms of dynamic stability, maintenance efficiency, and long-term operational savings make it a practical choice for many industries worldwide.

By understanding its design principles, features, and best practices for selection and maintenance, engineers and plant operators can ensure that cage guided double seated control valves deliver maximum value and performance throughout their operational lifespan.