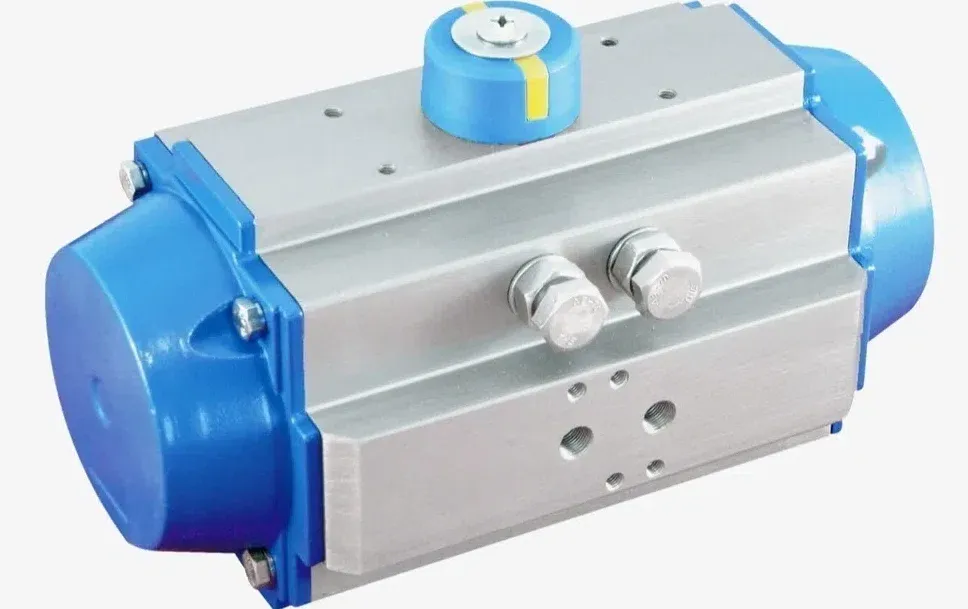

Pneumatic rotary actuators play a crucial role in industrial automation by converting compressed air energy into mechanical motion, typically rotary. These devices are widely used for automating valve operations, particularly for quarter-turn valves like butterfly and ball valves, across diverse industries including oil and gas, water treatment, power generation, and chemical processing.

Driven by clean, dry compressed air, these actuators offer fast and reliable motion in environments where electrical actuators may be unsuitable. Air is usually supplied from a centralized compressor system, although in certain cases, the process gas itself may be used as the driving medium. The exhaust air can either be vented directly into the atmosphere or recycled into a lower-pressure downstream system for efficiency.

In this article, we explore the structure, working principles, types, advantages, and applications of pneumatic rotary actuators in depth.

At its core, a pneumatic rotary actuator is a device that transforms the energy of compressed air into rotary motion. The actuator is made up of one or more air chambers where pressure is applied to a piston or diaphragm, creating motion. If the initial motion is linear (as in piston-driven designs), it is converted internally to rotary motion using mechanical linkages like gears or yokes.

These actuators are especially valued for their ruggedness, high power-to-weight ratio, and suitability in hazardous environments where electric sparks could pose safety risks.

The basic working principle of a pneumatic rotary actuator involves the application of air pressure to move internal components that generate rotational torque. Depending on the actuator type, air may be applied to one side (single acting) or both sides (double acting) of a piston or vane.

In single acting actuators, air pressure is applied on one side to move the actuator, while a spring returns the device to its original position once the air supply is removed.

In double acting actuators, compressed air is alternately applied to either side of the piston to generate bi-directional motion, providing greater control and higher cycling capabilities.

The generated motion is used to operate valves or rotate other mechanical devices in automated systems.

There are several different designs of pneumatic rotary actuators, each tailored for specific torque requirements, angular travel, and application environments. The most commonly used designs include:

Vane actuators consist of a rotor with attached vanes housed within a chamber. Air pressure is applied to one side of the vane, causing it to rotate within the chamber. The pressure difference across the vane generates the torque needed for motion. Vane actuators are compact, simple, and highly responsive, making them suitable for applications where fast two-position movement is required.

Advantages:

Compact design

Fast actuation

Low cost

Simple construction

Limitations:

Limited torque output

Wear on seals can reduce efficiency over time

Typically limited to 90° or 180° rotation

Rack and pinion actuators use a piston connected to a rack (a straight gear), which engages with a pinion (a circular gear). As air pressure moves the piston, the rack drives the pinion, producing rotary motion. These actuators offer a balance of torque, control, and compact size.

Advantages:

Precise motion control

High torque in a compact form

Commonly available in both single and double acting models

Limitations:

Gears may wear over time

Regular lubrication and maintenance required

Scotch yoke actuators use a yoke mechanism to convert linear piston movement into rotary motion. These actuators are known for generating high torque at the beginning and end of the stroke, making them ideal for heavy-duty applications such as pipeline valve actuation in oil and gas.

Advantages:

High breakaway torque

Ideal for valves requiring high initial torque

Robust construction for harsh environments

Limitations:

Larger and heavier than rack and pinion designs

Less uniform torque output across the rotation

Diaphragm actuators use flexible diaphragms rather than pistons to create motion. These are more common in the process industry for applications requiring clean and precise control.

Advantages:

Smooth operation

Ideal for corrosive or sensitive environments

Fewer moving parts = lower maintenance

Limitations:

Lower torque compared to piston designs

Limited availability in higher sizes or custom configurations

The selection between single acting and double acting pneumatic actuators depends on application-specific needs such as safety, energy consumption, and frequency of operation.

Also known as spring-return actuators, these use compressed air to move the actuator in one direction, while a spring returns it to its default position when air pressure is lost.

Key Features:

Fail-safe design (spring-return ensures position during air loss)

Lower air consumption

Used in safety-critical applications

Best For:

Emergency shut-off valves

Applications where default position is critical upon air failure

These actuators use air pressure to move the actuator in both directions, without a spring.

Key Features:

Higher torque output

Greater control precision

Ideal for high-cycle or continuous operations

Best For:

Frequent actuation requirements

Applications needing balanced force in both directions

When selecting the right actuator for your system, several important factors should be considered:

Ensure the actuator can deliver enough torque to operate the valve under all expected conditions, including breakaway, running, and seating torque.

Some actuators are designed for specific angles of rotation (90°, 120°, 180°, etc.). Make sure the rotation matches your valve requirements.

Actuation time may be critical in emergency shutdown systems or high-speed processes. Choose an actuator that meets the desired cycle speed.

If the actuator will be installed in a corrosive, high-temperature, or explosive environment, ensure it has the appropriate material and certifications (such as ATEX or ISO standards).

Verify compatibility with valve stems and mounting interfaces (ISO 5211 is a common standard). Some actuators come with adjustable mounting kits or accessories for flexible installation.

Pneumatic rotary actuators are used in a wide range of industrial and commercial applications due to their versatility, speed, and reliability. Some common application areas include:

Oil and Gas: Pipeline valve actuation, blowdown systems

Water and Wastewater Treatment: Valve control for fluid distribution

Power Plants: Steam and cooling systems

Chemical Processing: Controlling aggressive or hazardous media

Food and Beverage: Clean room automation, hygienic valve actuation

Pharmaceuticals: Sterile processes requiring precise and repeatable motion

High Speed and Responsiveness: Pneumatic systems respond quickly to control signals, ensuring fast actuation.

Simplicity and Low Maintenance: With fewer moving parts than electric or hydraulic systems, pneumatic actuators are generally easy to maintain.

Safety in Hazardous Areas: Since they don’t use electricity directly, they are ideal for explosive environments.

Cost-Effective: Lower upfront and operating costs compared to hydraulic or electric actuators, particularly in facilities already equipped with compressed air infrastructure.

While highly effective, pneumatic rotary actuators are not without limitations:

Dependence on Compressed Air: They require a reliable and clean air supply system, which may not be feasible in all environments.

Energy Inefficiency: Compressed air systems can be less energy-efficient compared to electric systems over long durations.

Control Limitations: Although improving, pneumatic actuators generally offer less precise control than servo-electric actuators.

The field of actuation technology is evolving. Pneumatic actuators are increasingly being integrated with smart technologies such as:

Positioners and Smart Controllers: For more precise control and feedback

IoT Integration: Enabling predictive maintenance and remote monitoring

Energy Recovery Systems: To improve the efficiency of compressed air use

Hybrid actuator systems that combine pneumatic with electric or hydraulic systems are also being explored to balance the advantages of each technology.

Pneumatic rotary actuators continue to be indispensable components in industrial automation due to their speed, simplicity, and suitability for rugged environments. Understanding their types, operation, and application contexts is essential for selecting the right actuator for your process needs.

Whether you’re automating valves in an oil refinery, managing fluid flow in a water treatment plant, or streamlining production in a food processing facility, pneumatic rotary actuators offer a reliable and efficient solution.

As industries move toward smarter and more connected systems, the role of pneumatic actuators will evolve further — combining traditional reliability with modern control and monitoring capabilities.