Pneumatic butterfly valves play a crucial role in fluid control systems across a wide range of industries. Known for their compact structure, rapid response, and ease of automation, these valves are particularly suitable for applications that require frequent switching and remote control. To ensure their long-term performance and reliability, proper maintenance practices are essential.

This article provides a comprehensive overview of pneumatic butterfly valves, including their structure, working principle, types, and detailed maintenance guidelines. Whether you're a maintenance engineer, plant manager, or a valve operator, understanding how to care for pneumatic butterfly valves will help extend their service life and maintain optimal system performance.

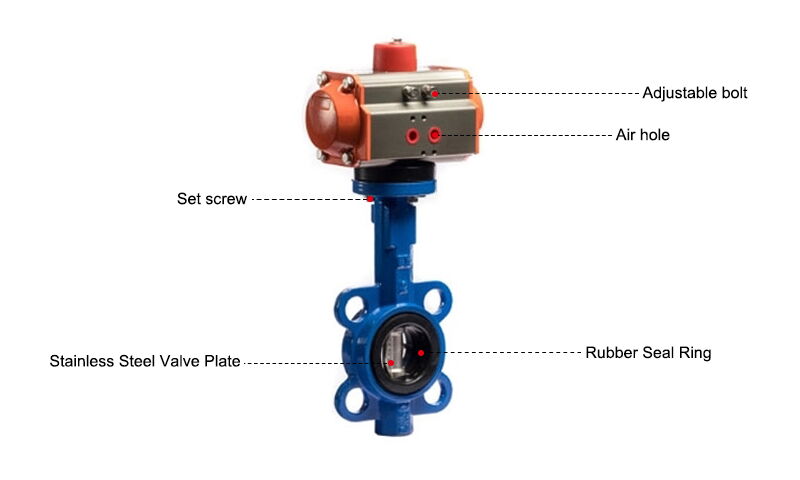

A pneumatic butterfly valve is an automated valve system composed of two main components: a pneumatic actuator and a butterfly valve body. It operates by using compressed air to drive the actuator, which in turn rotates a disc—also known as the butterfly plate—within the valve body. The disc rotates around a central stem and aligns either parallel or perpendicular to the flow of the medium, thereby opening or closing the valve.

These valves are typically used as shut-off devices, although they can also be designed for throttling or segmental flow control. Due to their quick-acting nature and simple mechanism, pneumatic butterfly valves are increasingly used in large and medium-diameter pipeline systems, especially where low-pressure service conditions are common.

Pneumatic butterfly valves come in various types, differentiated by the materials used and the sealing mechanism. Common classifications include:

Pneumatic Stainless Steel Butterfly Valves: Resistant to corrosion and suitable for sanitary or chemically aggressive environments.

Pneumatic Hard-Sealing Butterfly Valves: Designed for high-pressure or high-temperature conditions; offers a tight metal-to-metal seal.

Pneumatic Soft-Sealing Butterfly Valves: Incorporate an elastomeric seat for superior sealing under moderate conditions.

Pneumatic Carbon Steel Butterfly Valves: Cost-effective option for general industrial use.

Pneumatic Cast Iron Butterfly Valves: Commonly used in water supply systems and HVAC applications.

Each type offers distinct advantages depending on the application and media characteristics, such as fluid type, pressure, and temperature.

Compact Design: The valve’s low-profile structure makes it ideal for space-constrained installations.

Lightweight Construction: Easier to handle and install, particularly in overhead or vertical pipelines.

Cost-Effective: Simple structure translates to lower production and maintenance costs.

Fast Operation: Pneumatic actuators allow for rapid open-close cycles, improving system responsiveness.

Remote and Automated Control: Compatible with solenoid valves, positioners, and PLCs for seamless integration into automated systems.

These features make pneumatic butterfly valves especially suitable for installations in confined or elevated spaces, such as underground tunnels or elevated process lines, where manual operation would be difficult.

The pneumatic butterfly valve operates by using compressed air to drive the actuator, which in turn moves the stem and rotates the butterfly disc. The disc opens or closes the passage as it turns 90° around its axis. The control logic can be configured for two key actions:

From Fully Closed to Fully Open (and vice versa): The most common mode of operation.

Intermediate Positions for Flow Regulation: In applications where throttling is allowed (depending on the valve type).

There are two primary types of pneumatic actuators used in butterfly valves:

Require air pressure to both open and close the valve. These actuators are commonly used in systems where continuous air supply is available and where rapid switching is required.

Use air pressure for one direction (usually opening), while a built-in spring returns the valve to its default position when air pressure is removed. These are ideal for fail-safe applications—ensuring the valve closes automatically during air or power failure, enhancing system safety.

Due to the fast response time and simple mechanics, pneumatic butterfly valves are less susceptible to damage from jamming, and they offer reliable performance in frequent-cycle operations.

Regular maintenance is essential to keep pneumatic butterfly valves operating safely and efficiently. Poor maintenance can lead to leakage, premature wear, or actuator failure, which may compromise the entire system. The following sections outline essential tips for valve upkeep.

Ensure that the installation environment meets the valve’s operating requirements:

Moisture Protection: Use protective measures to shield the actuator and valve components from water ingress, which can corrode internal parts.

Clean Air Supply: The compressed air used should be free of oil, water, and dust. Install air filters or air preparation units upstream if necessary.

Temperature Control: Keep the valve within its specified operating temperature range to prevent seal degradation or actuator malfunction.

Accessibility: Although butterfly valves can be mounted in any position, choose an orientation that allows easy access for maintenance.

Correct Flow Direction: Ensure the valve is installed so that the flow direction aligns with the manufacturer’s markings, particularly for shut-off applications.

Secure Mounting: Ensure all flange bolts are properly tightened to prevent misalignment or leakage.

Lubrication: Periodically lubricate the moving parts of the actuator to ensure smooth operation. Check manufacturer recommendations for lubricant type and intervals.

Surface Cleaning: Keep the exterior of the valve and actuator clean. Remove dust, grease, and debris to prevent buildup that could impair movement or heat dissipation.

Do Not Use as Throttle (Unless Specified): Standard pneumatic butterfly valves are meant for fully open or fully closed positions. Using them to regulate flow may erode the sealing surface and reduce lifespan.

Avoid Excessive Torque: Only use the handwheel (if present) or appropriate automated control. Do not use levers, pliers, or other tools that could damage the valve shaft.

Check for Abnormal Sounds: Unusual noises during operation may indicate internal wear, foreign object interference, or actuator malfunction. Investigate and resolve promptly.

If disassembly is necessary for inspection or repair:

Protect Sealing Surfaces: Carefully handle the valve disc and seat to prevent scratches or dents that could impair sealing.

Follow Proper Sequence: Refer to the valve’s maintenance manual for step-by-step disassembly instructions. Pay special attention to spring-loaded actuators under tension.

Inspect Internals: Examine seals, discs, and actuator components for wear, corrosion, or deformation. Replace worn parts as needed.

In case of malfunction:

Isolate the Valve: Cut off air supply and isolate the valve from the process line before beginning inspection.

Diagnose the Cause: Look for air leaks, control signal issues, or physical obstructions.

Test Before Restarting: After repairs, perform a full operational test with air pressure before placing the valve back into service.

If the valve is not going to be used for an extended period:

Store in a Dry, Ventilated Area: Protect from moisture to avoid corrosion of metallic parts and degradation of seals.

Seal the Ends: Use caps or plugs to close the valve ends and prevent the entry of dust, debris, or insects.

Periodic Inspection: Even during storage, check the valve periodically for signs of rust, damage, or aging of seals.

Pneumatic butterfly valves offer significant advantages for automated flow control systems, including rapid operation, reliable sealing, and low maintenance requirements. However, like all mechanical devices, their performance depends heavily on proper care.

By adhering to recommended installation guidelines, performing regular maintenance, and promptly addressing operational issues, users can greatly extend the life of their pneumatic butterfly valves and ensure efficient system performance.

In high-demand industrial environments—whether in water treatment, chemical processing, HVAC, or energy—these valves play a critical role. A well-maintained pneumatic butterfly valve not only improves process reliability but also reduces downtime and total cost of ownership.

For best results, always follow the manufacturer’s technical documentation and consult professional service providers for complex repairs or installations. With the right approach, pneumatic butterfly valves will continue to deliver smooth, dependable operation for years to come.