Aerodynamic Noise in Control Valves

On this page

When gas or steam flows through a control valve, it generates noise, commonly referred to as "aerodynamic noise." Depending on the valve's size, flow rate, and the differential pressure across it, this noise can become loud enough to be irritating or even harmful to nearby workers. Understanding what causes aerodynamic noise and how to mitigate it is crucial for maintaining a safe and comfortable working environment.

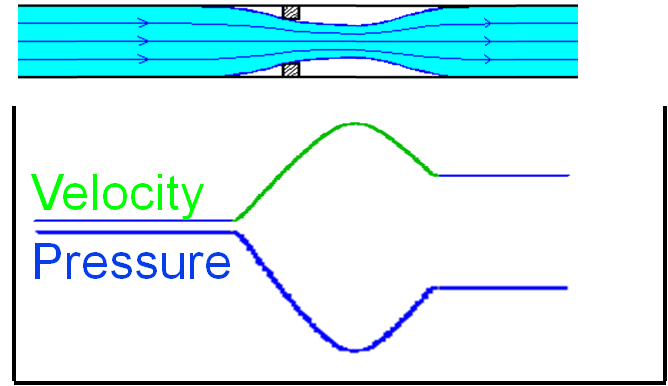

Figure 1. Velocity and Pressure Profile Inside a Control Valve

The generation of aerodynamic noise begins when gas flows past a restriction in a control valve, causing the velocity to increase and reach a peak at the vena contracta—the point of minimum cross-sectional area in the flow path. According to the law of conservation of energy, when the gas velocity increases, the pressure decreases, leading to the rapid expansion of the gas.

As the gas passes through the vena contracta, it expands rapidly due to the drop in pressure. Beyond this point, as the pressure rises again, the gas re-compresses. This rapid expansion and subsequent compression create severe turbulence, which is the primary source of aerodynamic noise. The intensity of the noise is closely related to the peak velocity of the gas. At subsonic velocities, the sound intensity in a free jet is proportional to the eighth power of the jet velocity. At supersonic velocities, the generation of shock waves makes the relationship between velocity and sound intensity even more pronounced.

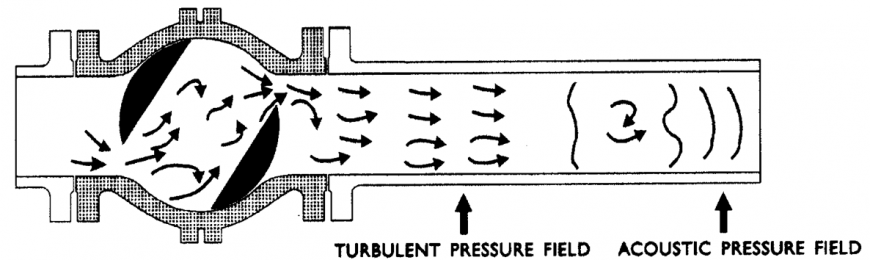

Figure 2. Generation of Aerodynamic Noise in a Control Valve

The aerodynamic noise generated by control valves can have significant impacts on both the working environment and the health of individuals. Noise levels can become high enough to cause irritation and fatigue among workers. In extreme cases, prolonged exposure to high levels of noise can lead to hearing damage. Additionally, high noise levels can interfere with communication and reduce overall productivity in industrial settings.

Several methods can be employed to reduce aerodynamic noise in control valves:

One effective way to reduce aerodynamic noise is to minimize the velocity of the gas in the valve. This can be achieved by selecting valves with larger flow paths or using multiple valves to share the flow load. Reducing the velocity decreases the turbulence and, consequently, the noise generated.

Trim Valves can be equipped with special anti-noise trims designed to break up the flow and reduce turbulence. These trims can significantly lower the noise levels by controlling the expansion and compression of the gas more smoothly.

Silencers can be installed downstream of the control valve to absorb and dissipate the sound energy. These devices are designed to target specific frequencies of noise and can be highly effective in reducing overall noise levels.

SourcesEnclosing the valve in a noise-insulating housing or using soundproof barriers around the noisy area can help contain the noise and prevent it from affecting nearby workers. This method is particularly useful in environments where noise reduction at the source is challenging.

Ensuring that the control valve operates within its optimal range of flow rates and pressures can prevent excessive noise generation. Regular maintenance and proper sizing of the valve for the specific application can help maintain these conditions.

Aerodynamic noise in control valves is a common issue in industrial settings where gas or steam flow is involved. Understanding the causes of this noise and implementing effective mitigation strategies is essential for creating a safer and more comfortable working environment. By minimizing gas velocity, using anti-noise trims, installing silencers, isolating noise sources, and maintaining optimal operating conditions, industries can significantly reduce the impact of aerodynamic noise. This not only protects the health and well-being of workers but also enhances overall operational efficiency and productivity.

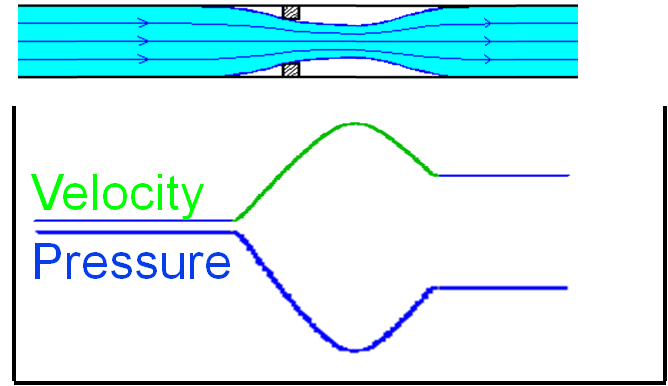

Figure 1. Velocity and Pressure Profile Inside a Control Valve

As the gas passes through the vena contracta, it expands rapidly due to the drop in pressure. Beyond this point, as the pressure rises again, the gas re-compresses. This rapid expansion and subsequent compression create severe turbulence, which is the primary source of aerodynamic noise. The intensity of the noise is closely related to the peak velocity of the gas. At subsonic velocities, the sound intensity in a free jet is proportional to the eighth power of the jet velocity. At supersonic velocities, the generation of shock waves makes the relationship between velocity and sound intensity even more pronounced.

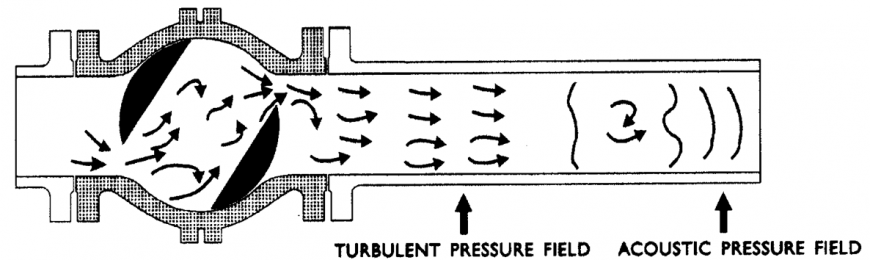

Figure 2. Generation of Aerodynamic Noise in a Control Valve