In modern industrial systems, maintaining precise control over fluid flow is crucial for ensuring operational efficiency, safety, and consistent product quality. Pneumatic control valves play an indispensable role in achieving this control by regulating the flow of liquids, gases, or slurries in a reliable and automated manner. Unlike manual valves that require human intervention, pneumatic control valves respond to external signals from controllers, adjusting their position to maintain the desired process parameters.

These valves are widely used across various industries, including chemical processing, petrochemical, power generation, water treatment, and pharmaceuticals, due to their robust performance, rapid response, and adaptability to challenging conditions such as high temperature, corrosive media, or explosive environments.

This article provides a detailed overview of pneumatic control valves, including their working principles, types, selection guidelines, and strategies for mitigating common operational issues such as noise, vibration, and cavitation.

A pneumatic control valve is a mechanical device designed to modulate the flow rate of process media using compressed air as the primary actuator. The valve receives control signals from a process controller or Distributed Control System (DCS) and adjusts its position accordingly to achieve the required flow rate, pressure, or temperature.

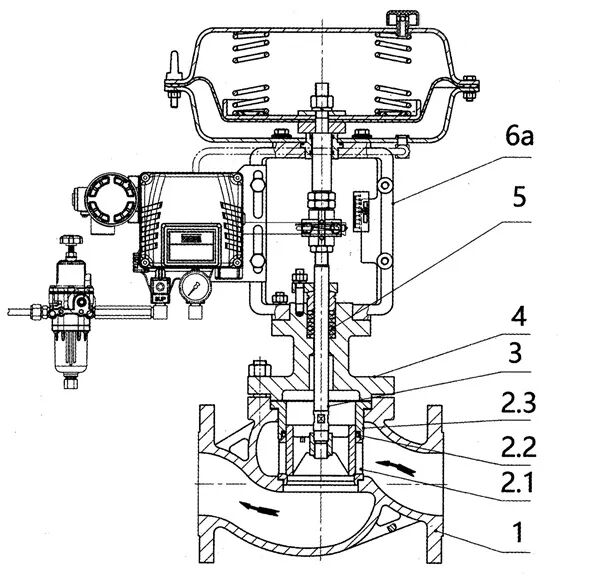

The core components of a pneumatic control valve include:

Actuator: Converts compressed air pressure into mechanical motion to operate the valve. The actuator can be of various types, such as diaphragm, piston, or spring-loaded actuators, depending on the required force and stroke.

Valve Body: Houses the internal mechanism—such as a globe, butterfly, ball, or sleeve—that regulates fluid flow. The valve body is designed to withstand process conditions, including pressure, temperature, and corrosive effects of the media.

Positioner: A device that ensures precise valve positioning by comparing the control signal with the actual valve position and making fine adjustments as necessary. Modern positioners may be pneumatic, electro-pneumatic, or intelligent digital types.

Pneumatic control valves can perform both throttling and on/off control functions, making them versatile tools for maintaining process stability.

The operation of a pneumatic control valve relies on the interaction between the actuator and the valve mechanism. When the controller sends a signal—typically a pneumatic or electrical signal converted into pneumatic pressure—the actuator responds by generating a mechanical thrust. This thrust moves the valve stem, which in turn moves the valve plug, disc, or sleeve within the valve body to modulate the flow of the process medium.

The type of valve body and its internal design influence the flow characteristics. Common configurations include:

Single-seat control valves: Suitable for moderate pressure drops and standard flow control.

Sleeve or piston valves: Designed to handle higher pressure drops and minimize leakage.

Three-way control valves: Used to mix two fluid streams or divide a single stream into two.

Angle control valves: Often applied where piping direction changes are required.

Additionally, specialized valves such as high-temperature, low-temperature, high-pressure, and small-flow valves are available to meet unique industrial requirements. Multi-stage cage valves can also be selected in applications prone to cavitation or flashing to reduce pressure in stages, ensuring stable and safe operation.

Choosing the right pneumatic control valve is critical for achieving optimal performance and extending the service life of the system. While pneumatic and electric control valves share similar control objectives, their operational mechanisms differ significantly. Pneumatic valves require a compressed air supply, while electric valves rely on electrical power, making pneumatic valves more suitable for hazardous or explosive environments due to their inherent safety.

Actuators are the driving force of pneumatic valves. When selecting an actuator, factors to consider include:

Stroke length and force requirement: Ensures the valve can fully open or close under all operating conditions.

Response time: Affects the speed at which the valve can react to control signals.

Explosion-proof requirements: Critical in chemical and petrochemical plants.

The choice of valve body material depends on the medium and environmental conditions:

Carbon steel: Common for general-purpose applications.

Stainless steel 304/316/316L: Offers excellent corrosion resistance for aggressive media.

Fluorine-lined valves: Suitable for highly corrosive chemicals.

Specialized materials or coatings may also be applied to resist erosion, cavitation, or extreme temperatures.

Different valve designs are optimized for varying flow and pressure conditions:

Single-seat valves: Ideal for low-pressure drop applications.

Double-seat valves: Handle higher flow rates but may have higher leakage; not suitable when zero leakage is required.

Sleeve valves: Effective in high-pressure drop scenarios with improved flow control.

Three-way valves: Used for mixing or diverting fluids efficiently.

Multi-stage cage valves: Reduce pressure in steps to prevent cavitation and flashing.

Positioners are essential for precise valve control:

Mechanical positioners: Simple and reliable but less accurate.

Intelligent digital positioners: Offer higher precision, diagnostics, and adaptability to process variations.

Noise, vibration, and cavitation are common challenges in pneumatic control valve operation, often caused by mechanical, fluid dynamic, or resonance issues. Addressing these problems is critical to prolong valve life and maintain system efficiency.

Vibrations can occur when the valve core moves within the sleeve. To minimize vibration:

Reduce the clearance between the valve core and sleeve.

Use hard-surfaced sleeves to resist wear and vibration.

Ensure proper installation alignment to reduce stress on moving parts.

High-velocity flow through the valve can create turbulence and noise. While some noise is unavoidable, cavitation exacerbates the issue. Solutions include:

Installing multi-stage pressure reduction valves.

Using anti-cavitation trims and diffusers.

Adjusting flow rates to reduce turbulence.

Components such as valve spools may have natural frequencies that resonate with system pulsations. Mitigation strategies include:

Changing spool design or material to alter vibration characteristics.

Replacing components with versions that dampen resonance.

Employing vibration dampers or supports for sensitive parts.

Oscillating movement of the spool due to pressure fluctuations can lead to noise and cavitation. Remedies include:

Re-adjusting the damping coefficient in the actuator.

Adding damping devices along the spool displacement path.

Ensuring proper calibration of the control loop to avoid overshoot or oscillation.

Pneumatic control valves offer several benefits over other types of valves:

Explosion-proof operation: Compressed air actuation makes them suitable for hazardous environments.

Low failure rate: Fewer electronic components reduce susceptibility to damage.

Simple maintenance: Mechanical simplicity ensures easy inspection and repair.

Fast response: Pneumatic actuators provide rapid valve movement for precise control.

Wide industrial applicability: Chemical, petrochemical, water treatment, and power industries widely rely on pneumatic valves for their reliability and performance.

Pneumatic control valves are employed in a broad range of industrial applications:

Chemical processing: Precise control of corrosive fluids.

Petrochemical plants: Handling hydrocarbons under high pressure and temperature.

Power plants: Steam and water flow regulation for turbines and boilers.

Water and wastewater treatment: Flow and pressure regulation for pipelines.

Food and beverage: Hygienic control of liquids in production lines.

Specialized applications, such as high-pressure or low-temperature environments, require careful selection of materials, valve type, and actuator specifications to ensure operational safety and reliability.

Understand Process Requirements: Determine pressure, flow, temperature, and media characteristics before selecting the valve.

Select Appropriate Valve Type: Consider single-seat, double-seat, sleeve, or three-way valves based on flow and pressure drop.

Choose Suitable Materials: Use corrosion-resistant materials for aggressive media.

Implement Proper Actuator and Positioner: Ensure fast, accurate, and safe valve actuation.

Plan for Maintenance: Ensure ease of access and availability of spare parts for routine inspections.

Mitigate Noise and Cavitation: Employ multi-stage cages, anti-cavitation trims, and damping mechanisms.

Verify Compatibility with Control Systems: Ensure the valve integrates seamlessly with DCS, PLCs, or other control platforms.

Pneumatic control valves are vital components in modern industrial systems, offering reliable, precise, and safe flow control for liquids, gases, and slurries. With proper selection, installation, and maintenance, these valves can provide long-term operational efficiency while reducing downtime, maintenance costs, and process variability.

From understanding the fundamentals of actuators and valve bodies to mitigating noise, vibration, and cavitation, industrial operators must carefully consider all aspects of pneumatic control valves. Their wide applicability across chemical, petrochemical, power, and water treatment industries demonstrates their versatility and indispensability.

For industries seeking robust, explosion-proof, and high-performance solutions, pneumatic control valves remain a preferred choice, balancing efficiency, safety, and reliability in demanding operational environments.

As technology evolves, intelligent pneumatic control valves with digital positioners and enhanced diagnostics are becoming increasingly common, offering higher precision, better adaptability, and more efficient process control than ever before.

By investing in the right pneumatic control valve and ensuring proper operational practices, companies can achieve smoother, safer, and more cost-effective process control, making these valves an essential component in today’s industrial landscape.