Across modern industrial sectors, achieving safe, efficient, and automated control of fluid and gas systems is essential for maintaining productivity and ensuring operational safety. Pneumatic actuated valves play a critical role in this landscape, offering robust performance and rapid response for a wide range of applications. Among them, the pneumatic actuated butterfly valve has emerged as one of the most versatile, cost-effective, and widely adopted valve types used for remote and automated flow regulation.

This news article takes an in-depth look at the design, working principles, applications, advantages, and maintenance practices of pneumatic actuated butterfly valves. As industries continue to evolve toward higher levels of automation and digital control, these valves remain fundamental components in pipelines and process systems across chemical processing, water treatment, food and beverage production, energy infrastructure, HVAC operations, and many other environments. Their simplicity, reliability, and adaptability make them a preferred choice for engineers, operators, and maintenance professionals around the world.

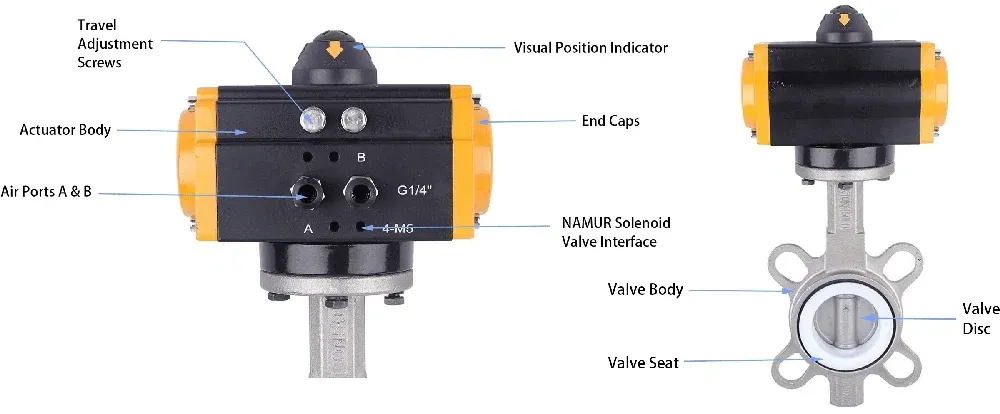

A pneumatic actuated butterfly valve is a flow-control device powered by compressed air. At its core, it consists of two critical components:

1. Butterfly Valve Body with Rotating Disc

2. Pneumatic Actuator Mounted on Top

When compressed air enters the actuator, it generates motion that rotates the valve disc by 90 degrees. This rotation either opens, closes, or modulates the flow of liquid or gas through the pipeline. Because air-powered actuators respond quickly and provide strong torque output, they are ideal for systems requiring high-speed actuation or frequent cycling.

Pneumatic actuated butterfly valves are favored for several reasons:

They are simple in structure yet extremely reliable.

They are safe for use in hazardous or flammable environments, since no electricity is required.

They provide excellent durability under continuous operation.

They offer an attractive cost advantage, especially for larger valve sizes.

Due to these strengths, industries ranging from chemical, pharmaceutical, petrochemical, wastewater treatment, food and beverage, oil and gas, bulk powder handling, and HVAC rely on pneumatic butterfly valves for daily operation.

A pneumatic actuated butterfly valve may come with either lug or wafer body styles, each suited for different installation requirements:

Designed to fit between two flanges

Held in place by flange bolts that surround the valve body

Lightweight and cost-effective

Commonly used in systems that do not require the pipeline to be disconnected on both sides simultaneously

Equipped with threaded lugs surrounding the valve body

Allows one side of the piping system to be disconnected without disturbing the other

Offers greater installation flexibility and isolation capability

Preferred in applications where regular line maintenance is required

Both types offer dependable flow control and are compatible with standard flange specifications, offering engineers flexibility in system design.

Pneumatic actuators use compressed air—typically between 4 to 8 bar (60 to 120 psi)—to generate the mechanical torque needed to rotate the valve disc. The two primary actuator types are single-acting (spring return) and double-acting.

A single-acting actuator operates using one air inlet and an internal spring.

Compressed air enters the actuator to rotate the disc to the open or closed position.

When air pressure is removed, the internal spring automatically returns the valve to its default position.

This default state is configured as either:

Fail-Open (disc returns to open position)

Fail-Close (disc returns to closed position)

Built-in safety mechanism

Provides automatic fail-safe operation during air or power loss

Ideal for emergency shutdown systems

Lower air consumption compared to double-acting models

Reliable in remote or unmanned installations

Emergency shutdown lines

High-risk installations in chemical plants

Water/air supply systems requiring automatic safe positioning

Systems requiring a quick response in failure scenarios

Single-acting pneumatic actuators are often preferred when safety and reliability under unexpected conditions are critical.

A double-acting pneumatic actuator uses two air inlets, providing air power for both opening and closing actions.

First air signal: Opens the disc

Second air signal: Closes the disc

No internal spring is used—air pressure alone controls both movements

Stronger torque output

Faster actuation speeds

Wider control range

Longer service life due to reduced internal mechanical stress

Provides precise control, making it suitable for automated modulation

High-pressure or high-flow pipelines

Industrial processes requiring frequent cycling

Actuation of large butterfly valves where torque requirements are high

Process systems requiring fast open/close sequences

Double-acting actuators are commonly used when performance, precision, and endurance are top priorities.

Pneumatic actuators have fewer failure points compared to electric actuators. They operate safely even in extreme temperatures or corrosive atmospheres and are resistant to overload conditions.

For sizes above 8 inches, pneumatic actuators are significantly more economical than electric actuators. They offer the best torque-to-cost ratio in the valve industry.

Compressed air enables quick response times, making pneumatic valves suitable for applications requiring instant action—such as safety systems or automated production lines.

Since they rely on air pressure rather than electric motors, pneumatic valves are inherently safe in explosive environments such as oil refineries and chemical processing facilities.

The design is simple, with fewer moving parts, resulting in lower maintenance costs and longer operational life.

Pneumatic actuated butterfly valves are used extensively across several sectors due to their versatility:

Acid/alkali pipelines

Process gas control

Solvent processing units

Their corrosion-resistant bodies and high torque capabilities ensure safe, stable control.

Pumping station flow regulation

Sludge handling

Disinfection systems

Light movement and reliable sealing make them suitable for continuous operations in these facilities.

Beverage mixing lines

Sanitary fluid handling

Clean-in-place (CIP) systems

Stainless-steel options ensure hygiene and compliance with sanitary requirements.

Purified water distribution

Solvent flow systems

Sterile production environments

High-precision control and contamination resistance are essential in these applications.

Air handling

Cooling water control

Chilled water circuits

Low pressure drops and fast response times support large building automation systems.

Power Generation

Cooling towers

Boiler feed systems

Chemical dosing stations

Long life and vibration resistance support demanding power plant operations.

Modern pneumatic actuated butterfly valves can be configured with a variety of materials to suit the application:

Cast iron

Ductile iron

Stainless steel (304, 316)

Aluminum bronze

Duplex stainless steel

Stainless steel

Nickel-plated discs

PTFE-coated discs for corrosive fluids

EPDM

NBR

VITON

PTFE

Silicone

Selecting the right material ensures compatibility with chemicals, temperature ranges, and pressure conditions.

With the expansion of smart factory systems, pneumatic butterfly valves can be equipped with:

Positioners for precise throttling

Solenoid valves for directional air control

Limit switches for open/closed feedback

Air filter regulators for clean and stable airflow

Smart controllers for integration into SCADA or PLC systems

This makes them suitable for Industry 4.0 environments.

Proper maintenance ensures long-term reliability and reduces the risk of unnecessary downtime. Essential practices include:

Check for air leaks or loose fittings

Inspect actuator seals and O-rings

Ensure disc and seat remain free of debris

Verify limit switch and solenoid wiring

Lubricate stem bearings and actuator moving parts

Prevents premature wear and friction

Perform full-stroke tests and partial-stroke tests

Verify opening/closing speed

Ensure fail-safe position works correctly

Actuator not moving: Check air supply and solenoid valve

Leakage at stem: Replace worn seals

Valve not sealing: Inspect disc and seat for damage

Slow operation: Check for insufficient air pressure

Implementing a preventive maintenance schedule—based on valve size, operating frequency, and environmental conditions—can greatly extend the service life of both valve and actuator.

The pneumatic actuated butterfly valve continues to be a cornerstone of industrial automation due to its reliability, efficiency, and adaptability. Whether in large-scale chemical processing, water treatment infrastructure, food production lines, or sophisticated HVAC systems, these valves deliver dependable performance while keeping operating costs manageable.

Their ability to provide rapid response, high torque output, safe fail-safe positioning, and compatibility with modern automation technologies ensures that they remain a vital component in fluid and gas handling systems. As industries evolve toward higher levels of efficiency and automation, the pneumatic actuated butterfly valve will continue to play a crucial role in maintaining safe, precise, and productive operations across countless industrial sectors.