Control valves are at the heart of industrial fluid management systems, regulating flow, pressure, and temperature to ensure process efficiency and safety. While much attention is often given to the valve body and actuator, the internal components—collectively known as the valve trim—play a critical role in determining how well a valve performs under demanding conditions. From cavitation to noise reduction, the trim design directly influences the lifespan, efficiency, and reliability of control valves in a wide range of applications.

In this article, we explore what control valve trims are, how they are selected, and the advanced trim designs that help mitigate cavitation and noise in industrial systems. We’ll also discuss practical considerations for valve sizing and performance optimization.

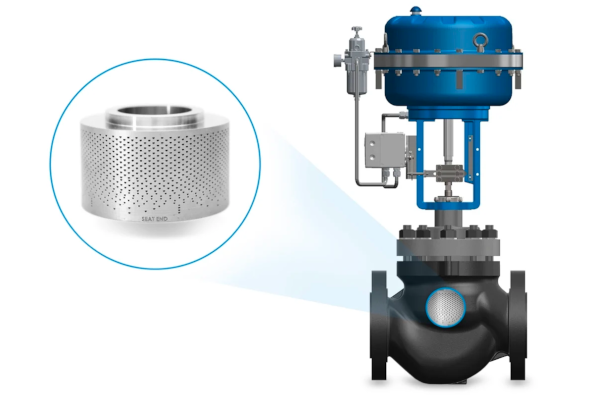

Control valve trim refers to the internal, replaceable components of a valve that come into direct contact with the process fluid. These components are critical to the valve’s operation and include items such as valve stems, plugs, seats, packing sets, and gaskets. Essentially, any wetted part inside the valve that can be disassembled and replaced is considered part of the trim. It is important to note that the valve body and bonnet, while they also contact the process fluid, are not classified as trim.

The trim plays a central role in determining the valve’s overall performance. Its design and material selection directly influence the valve’s durability, control precision, and resistance to operational challenges such as corrosion, wear, cavitation, and noise. In high-pressure or high-velocity applications, the trim must be carefully engineered to handle the stresses of fluid flow, pressure drops, and potential erosive or corrosive effects.

Advanced trims, such as multi-stage or specialized flow designs, can help manage flow energy, reduce turbulence, and minimize damage to both the valve and the surrounding system. By selecting the appropriate trim type and material, engineers ensure reliable valve operation, extend service life, and maintain efficient and safe control of industrial processes.

Valve sizing is a crucial step in ensuring optimal performance. Engineers determine valve size based on the flow coefficient (Cv) and the speed requirements of the application. The Cv measures the valve’s capacity to pass fluid and is a key parameter for selecting the appropriate trim and valve size.

Sometimes, a valve may have a Cv lower than the maximum possible for its size, necessitating a reduced setting. This situation arises primarily for two reasons:

Often, industrial guidelines specify that a control valve should not be less than half the diameter of the pipeline. For example, a 1-inch valve might be the smallest size recommended for a particular line, even if the flow rate requires a lower Cv. In such cases, trim adjustments are made to match the flow without oversizing the valve.

In gas or high-pressure steam systems, valves are frequently sized according to speed limits rather than Cv alone. Here, the required Cv may be significantly smaller than the valve’s total internal diameter, again requiring specialized trim designs to maintain safe and efficient operation.

Proper trim selection in combination with correct sizing ensures that valves operate within design limits, preventing excessive wear, vibration, and potential system damage.

Cavitation is one of the most common and damaging phenomena in control valves, occurring when fluid pressure drops below its vapor pressure, forming vapor bubbles that collapse violently. Over time, cavitation can erode metal surfaces, damage valve seats, and reduce system reliability. Advanced trim designs aim to reduce pressure in a controlled manner, slow fluid velocity, and prevent vapor bubble formation.

Multi-stage trims break down the total pressure drop into a series of smaller, controlled steps. By avoiding a single sharp pressure drop, these trims minimize the risk of cavitation even in high-pressure applications. Each stage dissipates energy gradually, ensuring the fluid remains above its vapor pressure.

This approach is particularly useful in:

High-pressure steam systems

Hydraulic processes with substantial pressure differentials

Gas pipelines where sudden drops could induce cavitation

Some trims incorporate specialized valve discs designed to split the fluid flow into multiple smaller streams. By distributing flow more evenly, local pressure drops are reduced, which helps prevent vapor bubbles from forming. These compact disc designs are highly effective in moderating cavitation while maintaining overall valve efficiency.

Stacked disc trims force fluid through a tortuous path, often comprising discs with precisely engineered holes or slots. This staged flow reduction slows the fluid at each step, lowering both velocity and pressure in a controlled manner. Stacked disc trims offer dual benefits:

Cavitation reduction

Noise control

They are often selected for applications where both fluid-induced noise and cavitation are significant concerns.

Some trim designs feature carefully shaped flow channels that guide fluid away from sensitive areas within the valve. By controlling flow direction and energy dissipation, these trims minimize cavitation risk while maintaining efficient operation. They are especially effective in applications requiring precise control of high-energy fluids.

Valve noise can be more than just an operational nuisance; it can indicate turbulent flow, excessive velocity, or potential damage within the system. Noise in control valves arises primarily from:

High fluid velocity

Turbulence

Large pressure drops

Engineers use trim design to smooth the flow, control velocity, and absorb energy, thereby reducing sound levels without compromising flow control.

Low-noise trims distribute the fluid through multiple small flow paths instead of a single large opening. This reduces velocity and turbulence, preventing the formation of high-energy jets that generate noise. They are widely used in gas and steam applications where high-velocity flow is inevitable.

Similar to cavitation-focused multi-stage trims, anti-noise trims reduce pressure in a series of controlled steps. Each stage dissipates energy gradually, lowering velocity and keeping sound levels within acceptable limits. These trims are particularly effective for applications with large pressure drops, such as:

Steam turbine bypass systems

Compressed air networks

High-pressure gas pipelines

In some advanced applications, air injection trims introduce small amounts of air into the fluid flow. The air absorbs sound energy and dampens noise without affecting valve performance. This technique is commonly used in high-pressure gas systems and offers an additional layer of noise suppression.

Selecting the right trim is both an art and a science, requiring engineers to balance multiple factors:

Fluid type: Steam, gas, or liquid fluids each have different cavitation and noise characteristics.

Pressure drop: Larger pressure drops require multi-stage or specialized trims.

Valve size vs. pipeline size: Oversized valves with low flow rates often need reduced trims to avoid instability.

Operating temperature: High temperatures can affect material selection for trim components.

Maintenance requirements: Easily replaceable trims simplify routine maintenance and reduce downtime.

By carefully considering these factors, engineers can extend valve life, maintain process efficiency, and minimize operational risks.

With increasing demand for energy efficiency, noise reduction, and longer service life, trim technologies are evolving rapidly. Some of the latest developments include:

High-performance alloys and coatings: Enhance resistance to cavitation and erosion.

Computational fluid dynamics (CFD) optimization: Allows precise design of flow paths to minimize turbulence and noise.

Hybrid trim solutions: Combine multiple design principles, such as stacked discs with specialized flow channels, for optimal performance in extreme conditions.

Smart valve trims: Integrate sensors to monitor flow and cavitation in real-time, enabling predictive maintenance and system optimization.

These advancements highlight the critical role of trims not just in controlling fluid flow, but in shaping the overall reliability and efficiency of industrial systems.

Valve trim design is a key factor in the performance, safety, and longevity of control valves. From cavitation-resistant multi-stage trims to low-noise designs and air injection techniques, modern trim engineering addresses some of the most challenging aspects of industrial fluid control.

Proper trim selection, combined with careful valve sizing and material choice, ensures that control valves operate efficiently under varying conditions. As industries continue to demand higher performance, smarter, and more durable solutions, valve trims will remain at the forefront of innovation, protecting critical systems from cavitation, noise, and wear.

By understanding the nuances of valve trim design, engineers can make informed decisions, optimize system performance, and reduce long-term maintenance costs, ensuring reliable operation in even the most demanding applications.