In modern fluid control systems, the motorized gate valve — also known as an electric sluice valve — plays a vital role in regulating the flow of liquids and gases. Unlike other valve types, a gate valve operates by lifting a barrier, or “gate,” out of the path of the fluid, allowing unobstructed flow. This simple yet highly effective mechanism enables minimal pressure drop when the valve is fully open, making it ideal for pipelines where maintaining flow efficiency is crucial.

With the integration of an electric actuator, gate valves can now be operated remotely, automated through PLCs (Programmable Logic Controllers), or controlled via analog signals such as 4–20 mA. This electric operation enhances safety, efficiency, and ease of operation while offering manual override options in case of emergencies or power outages.

Electric gate control valves are widely used in industries such as water treatment, oil and gas, power generation, chemical processing, and HVAC systems. Their ability to handle large volumes of fluid, high pressures, and aggressive media makes them indispensable in both industrial and municipal applications.

A motorized gate valve controls flow by moving a gate vertically inside the valve body. When the valve is fully open, the gate is lifted entirely out of the flow path, allowing fluid to pass freely. Conversely, when fully closed, the gate creates a tight seal to stop fluid flow completely. This “on-off” operation is highly efficient because it avoids partial obstruction and minimizes turbulence inside the pipeline.

In an electric gate valve, the gate is moved by an electric actuator. The actuator converts electrical energy into mechanical motion, driving the gate to open or close according to operational commands. This setup allows for precise control and integration with automated control systems, significantly reducing the need for manual operation.

A motorized gate valve consists of several essential components that work together to ensure reliable operation:

The valve body serves as the housing for all internal components. It is designed to withstand high pressures, corrosive fluids, and varying temperatures. Materials typically include stainless steel, ductile iron, carbon steel, or bronze, depending on the intended application and fluid type.

The gate disc is the sliding element that blocks or allows fluid flow. The disc may be solid or wedge-shaped, with designs such as parallel, flexible, or solid wedges to ensure tight sealing. The gate’s smooth movement within the valve body is critical for operational efficiency.

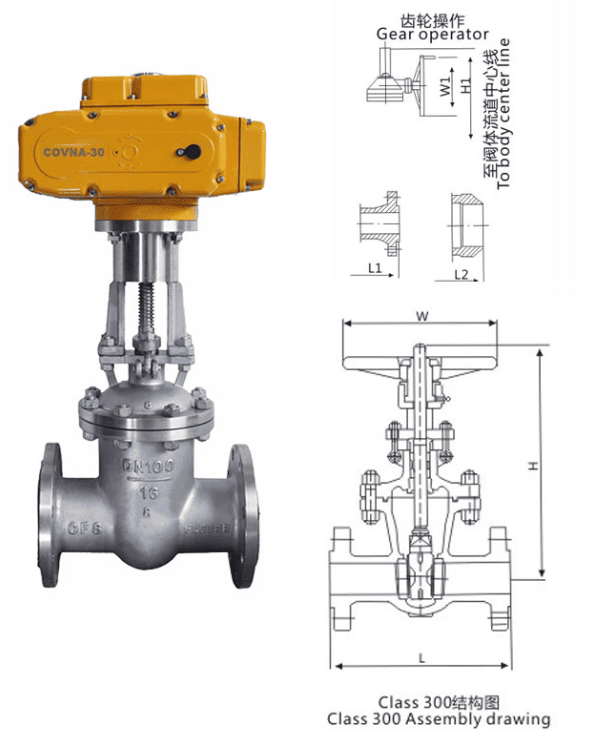

The stem connects the gate disc to the actuator and transmits motion. Stems may be rising or non-rising, depending on whether the external stem moves when the valve opens or closes. Rising stems offer a visual indication of valve position, while non-rising stems are preferred for space-limited installations.

The electric actuator supplies the operational force needed to lift or lower the gate. These actuators can be AC or DC powered and are often equipped with torque control, overload protection, and position feedback systems.

Some motorized gate valves include a gearbox to boost torque while reducing actuator speed. This allows the valve to operate smoothly even under high-pressure conditions or with large gate sizes.

Limit switches indicate when the valve is fully open or fully closed. They provide safety interlocks and signal feedback to control systems for accurate process monitoring.

The position indicator provides a visual display of the valve’s current position, helping operators quickly assess whether the valve is open, partially open, or closed.

The primary function of a motorized gate valve is to control the flow of fluid. When the electric actuator drives the stem, the gate moves up or down, opening or closing the valve. This simple yet robust mechanism ensures minimal flow restriction, making gate valves ideal for pipelines where unobstructed flow is critical.

Electric gate valves are capable of automated operation, improving production efficiency and reducing manual labor. Integration with PLC systems allows precise regulation of flow rates and automatic responses to changing process conditions.

One of the main advantages of motorized gate valves is the ability to monitor and control them remotely. By connecting the valve to a centralized control system, operators can open or close the valve from a control room or even offsite. This feature enhances safety, reduces the need for on-site personnel, and supports advanced process automation.

Motorized gate valves are typically constructed from high-strength metals and engineered to withstand high pressures, elevated temperatures, and corrosive media. The robust structural design ensures a long service life, even under frequent operation and harsh industrial conditions.

Motorized gate valves are highly versatile and used in a wide range of industries:

Gate valves are commonly installed in municipal water treatment plants, pumping stations, and wastewater facilities. Their ability to fully open or close allows for efficient control of water flow, maintenance isolation, and emergency shutdowns.

In upstream, midstream, and downstream pipelines, electric gate valves manage the flow of crude oil, natural gas, and refined products. Their strength and reliability make them suitable for high-pressure pipelines and critical control points.

Power plants rely on motorized gate valves to regulate steam, cooling water, and fuel supply systems. Electric actuation allows precise control over high-temperature and high-pressure fluids, ensuring stable plant operation.

Handling aggressive chemicals, acids, and caustic liquids demands valves that are resistant to corrosion and capable of sealing reliably. Motorized gate valves made of stainless steel or corrosion-resistant alloys meet these requirements.

Large-scale heating, ventilation, and air conditioning systems use electric gate valves to control water and coolant flow, supporting temperature regulation and energy efficiency.

Sanitary electric gate valves with stainless steel construction are used in food processing and beverage production for hygienic fluid control. Their smooth internal surfaces reduce contamination risks and allow easy cleaning.

Because the gate fully retracts from the flow path, pressure loss and turbulence are minimized, unlike globe or butterfly valves that partially obstruct the flow.

Electric gate valves are compatible with PLCs, SCADA systems, and remote control networks, enabling centralized management of multiple valves in industrial facilities.

Equipped with limit switches, position indicators, and torque control, motorized gate valves enhance operator safety and provide reliable feedback to prevent mechanical or electrical faults.

Robust design, high-quality materials, and precise engineering ensure decades of operation under normal industrial conditions, even with frequent cycling.

Motorized gate valves are suitable for various fluids, pressures, and temperatures, and they can be configured for rising or non-rising stem designs, multiple sealing types, and flange or wafer connections.

Selecting the right motorized gate valve requires careful consideration of several factors:

Media type: Water, oil, steam, corrosive fluids, or slurries

Pressure and temperature ratings: Ensure compatibility with process conditions

Valve size: Based on flow requirements and pipeline diameter

Material selection: Stainless steel, carbon steel, bronze, or alloy depending on fluid and environment

Actuation type: Electric actuators should meet torque, speed, and control system requirements

Maintenance accessibility: Easy access to actuator, gearbox, and gate components ensures minimal downtime

Install the valve according to manufacturer specifications.

Ensure the valve is aligned properly with the pipeline to prevent stress on the stem or body.

Connect the electric actuator to the control system, ensuring proper voltage and signal compatibility.

Verify the valve can operate fully open and fully closed without obstruction.

Confirm grounding and earthing to prevent electrical hazards.

Conduct regular inspections for leaks, corrosion, or mechanical wear.

Test the actuator and limit switches periodically to ensure proper functionality.

Lubricate moving parts if required by the manufacturer.

Check the valve position indicator for accuracy.

Avoid over-torqueing or forcing the gate beyond its designed limits.

Proper maintenance extends the service life of motorized gate valves and reduces the risk of operational failure, protecting both equipment and personnel.

Motorized gate valves, or electric sluice valves, are indispensable components in modern fluid control systems. Their ability to provide efficient flow regulation, automated operation, remote monitoring, and long-term durability makes them a preferred choice across water treatment, oil and gas, power generation, chemical processing, HVAC, and food industries.

Key benefits include:

Precise fluid control with minimal flow restriction

Automation compatibility for centralized control and process optimization

Enhanced safety through limit switches and position indicators

High strength and corrosion resistance, ensuring long service life

Whether you are upgrading an industrial plant, installing a municipal water system, or integrating smart control in a factory, motorized gate valves offer the performance, reliability, and operational flexibility necessary for today’s complex systems.

As industries continue to advance toward automation, electric gate valves will remain at the forefront of efficient, safe, and reliable fluid control.