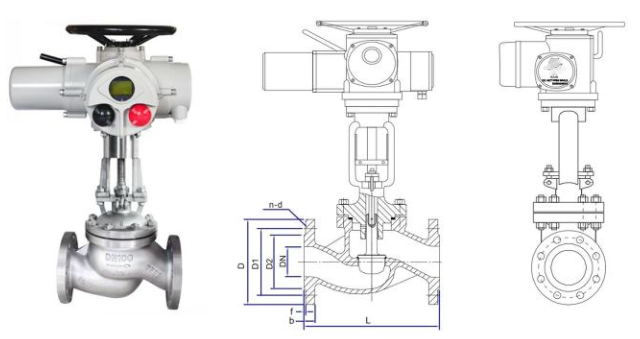

The multi-turn electric actuated globe valve represents a vital integration of mechanical engineering and intelligent automation technology, designed to optimize fluid control in diverse industrial applications. This advanced valve assembly combines a globe valve with an intelligent multi-turn electric actuator, delivering superior reliability, precise modulation, and ease of operation. With the ability to support both remote and local control, the multi-turn electric globe valve has become indispensable in industries ranging from power generation to petrochemicals, wastewater treatment, and beyond.

Equipped with features such as an LCD display, infrared remote control (optional), and simplified setup without the need to open the actuator lid for debugging, this system provides a durable, high-cost-effective solution for modern fluid management challenges. Its valve body is engineered to prevent backflow, ensuring the stability and reliability of the entire fluid control network.

As a leading manufacturer of electric actuated valves, we offer both multi-turn and quarter-turn electric actuators to meet varied project requirements, ensuring optimal integration with gate valves, globe valves, diaphragm valves, plunger valves, throttle valves, and water gates. Whether used with rising stem or non-rising stem valves, these actuators deliver precise control while maintaining robust performance under demanding industrial conditions.

A multi-turn electric valve actuator is a device that drives valves to open, close, or modulate flow automatically or via remote control. Unlike simpler quarter-turn actuators, multi-turn actuators rotate the valve stem multiple turns to achieve precise adjustments, making them ideal for regulating flow rates in critical systems.

These actuators are suitable for a broad range of valves:

Gate valves – for on/off control of liquids in pipelines.

Globe valves – for precise flow regulation.

Diaphragm valves – for corrosive or slurry fluids.

Plunger valves – for high-pressure systems.

Throttle valves and water gates – for water treatment or hydroelectric applications.

The multi-turn series stands out due to several key characteristics:

Complete functionality: Capable of manual operation, remote control, and integration into automated systems.

Reliable performance: Designed to withstand harsh industrial environments with minimal maintenance.

Compact design: Small size and light weight reduce installation space and simplify handling.

Ease of use: Setup, calibration, and operation are straightforward, minimizing downtime.

These actuators can be integrated into centralized control systems, allowing operators to manage multiple valves from a single control room. Additionally, the system supports automatic control, which is particularly useful in scenarios requiring constant adjustment based on process variables such as pressure, flow rate, or temperature.

Multi-turn electric actuators are designed to meet diverse industrial requirements. They are classified based on protection types, control modes, and connection types:

Outdoor Type: Engineered to withstand extreme weather conditions, UV exposure, and high humidity, ensuring stable operation in outdoor installations.

Explosion-proof Type: Designed for hazardous environments where flammable gases, vapors, or dust may be present. The actuator’s construction prevents sparks or heat generation that could ignite the surrounding atmosphere.

Intelligent On-Off Type: Provides simple open/close operation, suitable for applications where precise modulation is not critical but reliable actuation is essential.

Intelligent Modulating Type: Offers continuous control of valve position, allowing fine adjustments to flow rate, pressure, or temperature in complex process systems.

Torque Type: Ideal for valves requiring rotational force, such as gate and globe valves.

Power Station Type: Integrates with larger automation systems for industrial-scale operations.

Thrust Type: Suitable for valves requiring linear motion, such as rising stem valves or plunger valves.

This flexibility ensures that multi-turn electric actuators can be tailored to the exact requirements of any project, whether it involves small-scale installations or large industrial plants.

The combination of a globe valve with a multi-turn electric actuator provides unique advantages over traditional manual or semi-automatic valves.

The design allows for easy electrical connection and seamless integration with industrial control systems. Both wired and wireless communication options are available, enabling centralized monitoring and operation.

Globe valves are known for their precise linear flow characteristics, making them ideal for modulating applications. When paired with an intelligent multi-turn actuator, the system can achieve exact flow control, even under variable pressure and temperature conditions.

These valves can be operated remotely via the actuator interface or manually in case of power failure. The built-in manual override ensures continued operation, enhancing system reliability.

Multi-turn electric globe valves are widely used in sectors including:

Power generation – controlling steam and water flow in turbines and boilers.

Oil and gas – regulating crude oil, natural gas, and refined products in pipelines.

Paper and pulp – managing chemical flows and water treatment processes.

Chemical industry – controlling corrosive or hazardous media.

Water and wastewater treatment – precise control of inflow, outflow, and treatment processes.

Modern multi-turn actuators support multiple industrial communication standards:

Profibus Fieldbus

Modbus Fieldbus

Hart Fieldbus

FF Fieldbus (Foundation Fieldbus)

DeviceNet Fieldbus

This wide range of communication options ensures compatibility with existing control systems, enabling real-time monitoring, data logging, and predictive maintenance.

Investing in multi-turn electric actuated globe valves provides several tangible advantages:

The precise stem rotation of the multi-turn actuator allows for accurate modulation, which is crucial for applications where even small deviations in flow rate or pressure can impact process efficiency or safety.

Explosion-proof and outdoor-rated actuators ensure safe operation in extreme or hazardous environments, protecting both personnel and equipment.

With a robust design and high-quality materials, these valves require minimal maintenance. The actuator’s sealed construction prevents dust and moisture ingress, prolonging operational life.

Although initial investment may be higher than manual valves, the reduced labor costs, enhanced system performance, and lower downtime translate into long-term savings.

Integration with industrial automation systems enables operators to monitor valve status, adjust settings, and receive alerts remotely. This is particularly valuable for large plants with geographically dispersed equipment.

The versatility of multi-turn electric globe valves has led to widespread adoption across various sectors:

Power Plants: Control of steam, water, and cooling systems.

Petrochemical Industry: Handling flammable liquids and gases with precise control.

Chemical Manufacturing: Accurate dosing of chemicals and regulation of reactions.

Metallurgy: Controlling cooling water, slag, and other fluids in furnaces and rolling mills.

Pulp and Paper: Managing water, chemicals, and pulp slurry for consistent production quality.

Sewage and Water Treatment: Regulating inflows, filtration processes, and sludge management.

In addition, industries such as pharmaceuticals, food and beverage, and HVAC systems also benefit from the precise modulation and automation capabilities of multi-turn actuated globe valves.

To maximize the performance and lifespan of multi-turn electric globe valves, certain best practices should be followed:

Proper Sizing – Ensure valve and actuator size match the system’s flow rate and pressure requirements.

Orientation and Positioning – Install valves according to manufacturer recommendations to prevent damage to the actuator or valve components.

Electrical Connection – Follow wiring diagrams closely; consider surge protection and grounding for safety.

Routine Inspection – Check actuator calibration, mechanical linkage, and communication interfaces regularly.

Preventive Maintenance – Lubricate moving parts as recommended and replace seals or components before wear compromises performance.

By adhering to these guidelines, facilities can ensure consistent valve operation, reduce downtime, and extend the overall service life of their automation systems.

As industrial automation advances, multi-turn electric actuated valves are evolving to meet higher demands for precision, connectivity, and energy efficiency. Key trends include:

Smart Actuators – Integration with IoT systems for real-time diagnostics, predictive maintenance, and remote updates.

Energy-efficient Design – Reduced power consumption without compromising performance.

Enhanced Materials – Use of corrosion-resistant alloys, composites, and coatings for longer life in harsh environments.

Cybersecurity – Secure communication protocols to protect critical infrastructure from unauthorized access.

Modular Designs – Easier replacement of components and upgrades without full system downtime.

These innovations are driving higher reliability and performance across industries, making multi-turn electric actuated globe valves central to modern fluid control strategies.

Multi-turn electric actuated globe valves combine precise modulation, robust design, and intelligent automation to provide unmatched reliability and performance in fluid control systems. Their adaptability across industries, from power generation to chemical processing, ensures consistent operation, improved safety, and reduced maintenance costs.

With features like remote monitoring, multiple communication protocols, explosion-proof designs, and optional infrared control, these valves meet the evolving demands of modern industrial systems. Whether used for on/off control or continuous modulation, multi-turn electric actuated globe valves represent a critical investment in efficiency, safety, and long-term operational excellence.

As a leading manufacturer of electric actuated valves, we provide customized solutions tailored to project requirements, offering both multi-turn and quarter-turn actuators to ensure optimal control and reliability in every installation.