In the world of process automation and fluid control, selecting the right type of control valve is crucial for achieving desired performance, safety, and operational efficiency. Among the wide variety of valves used in industrial settings, two types often compared are pneumatic control valves and self-operated control valves. Each serves a unique role and has distinct features, benefits, and limitations. Understanding how they function, where they excel, and the circumstances under which they should be used can help engineers and plant operators make informed decisions.

This article offers an in-depth comparison between pneumatic control valves and self-operated control valves, exploring their principles of operation, design considerations, application scenarios, and performance differences.

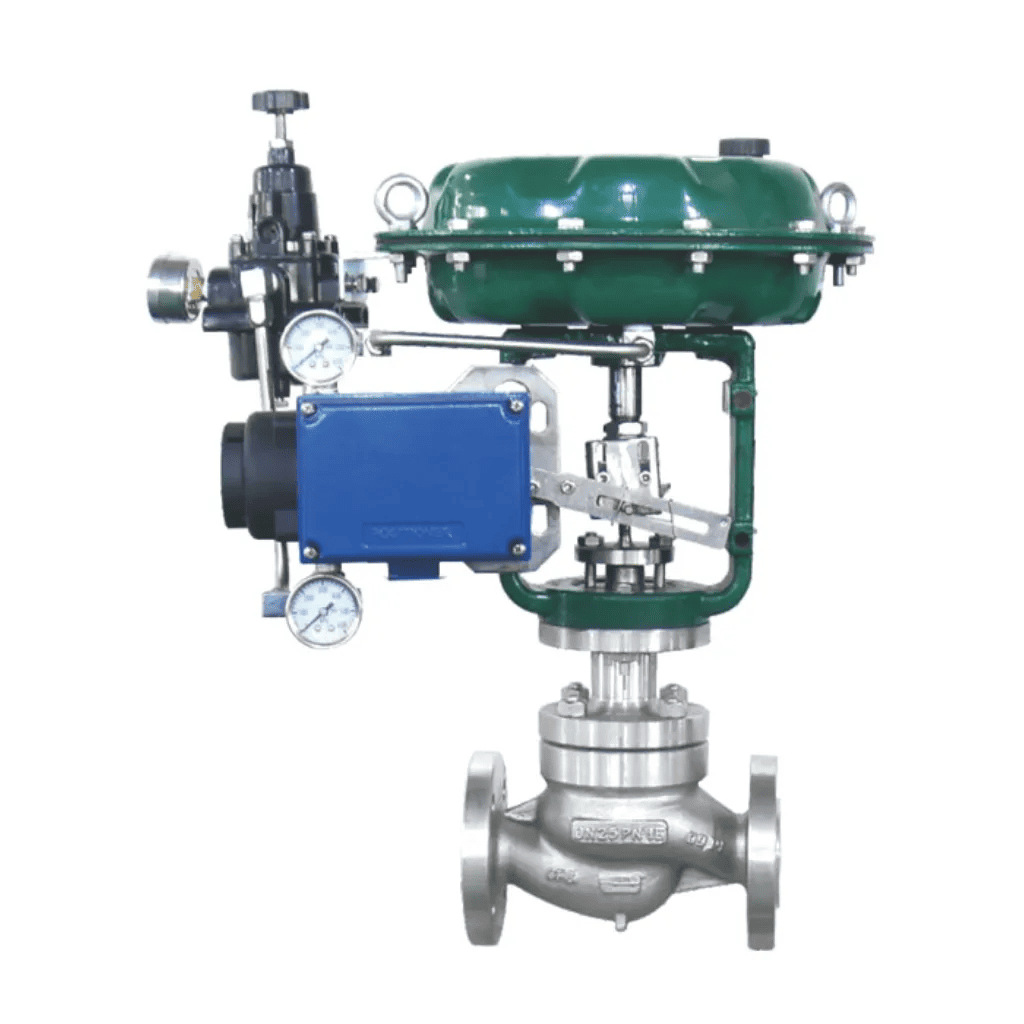

A pneumatic control valve is a type of automatic valve that uses compressed air as the driving energy. It consists primarily of a valve body and a pneumatic actuator. This valve plays a pivotal role in regulating fluid flow, pressure, temperature, or level within a system by receiving signals from a central control system such as a DCS (Distributed Control System) or PLC (Programmable Logic Controller).

The working mechanism involves a control signal—typically 4-20 mA or 0.2-1 bar—being sent to a positioner, which adjusts the actuator accordingly. The actuator, powered by compressed air, moves the valve plug or disc, altering the flow path within the valve and thereby adjusting process variables as needed.

Key Features:

Requires an external air supply and signal input.

Responds rapidly to changes in the control signal.

Offers high precision in regulating flow and pressure.

Common in systems requiring frequent and dynamic adjustments.

A self-operated control valve, as the name suggests, functions independently without the need for external power or control signals. It harnesses the energy of the process medium—usually pressure or temperature—to automatically adjust the valve opening. These valves are equipped with sensors (often diaphragms or bellows) that react to the process conditions and regulate the flow accordingly.

Self-operated valves are designed for simplicity and reliability in applications where precise control is not critical, and where utility infrastructure like air supply or power may not be available.

Key Features:

Operates without external power or instrumentation.

Uses the pressure or temperature of the medium itself to function.

Best suited for static or rarely adjusted systems.

Often used in small to medium-scale pipelines, especially for pressure reducing or pressure relief tasks.

Pneumatic Control Valve: Operates through external energy—primarily compressed air—and receives electronic or pneumatic signals from a control system. This enables remote operation, making it suitable for automated systems.

Self-Operated Control Valve: Functions autonomously. It doesn't rely on a separate control system or compressed air. Instead, it uses the process fluid's own pressure or temperature as the driving force.

Verdict: If remote and dynamic control is needed, pneumatic control valves are the go-to option. For standalone systems with limited infrastructure, self-operated valves are more practical.

Pneumatic Control Valve: Offers superior control accuracy, often achieving static accuracy in the range of 0.3% to 0.5%. The precision depends on the quality of the actuator, positioner, and control loop but is generally high due to the feedback mechanisms and advanced electronics.

Self-Operated Control Valve: Has lower control accuracy, generally around ±5% to ±10%, mainly limited by the mechanical characteristics of the spring and diaphragm used. It operates on a proportional control basis with some inherent lag and residual error.

Verdict: For applications where fine control is essential, such as in chemical dosing or high-precision temperature control, pneumatic valves are preferable. Self-operated valves are better suited for coarse adjustments.

Pneumatic Control Valve: Easily adjustable through the control system. The setpoint can be modified in real time, allowing for adaptive process control and integration into complex automation schemes.

Self-Operated Control Valve: The setpoint must be adjusted manually, usually on-site, by changing spring tension or preset parameters. This limits its use in scenarios that require frequent changes or remote adjustments.

Verdict: Pneumatic control valves excel in systems requiring flexibility, real-time optimization, and frequent tuning. Self-operated valves are ideal for "set-it-and-forget-it" tasks.

Pneumatic Control Valve: Requires proper infrastructure including air supply lines, control cabling, and signal interfaces. Installation may be more complex, and periodic maintenance of the actuator, positioner, and air system is necessary.

Self-Operated Control Valve: Easier and faster to install, as it requires no external energy or control wiring. Maintenance is generally lower, limited to occasional inspection of diaphragms or bellows.

Verdict: For remote or low-maintenance environments, especially where electrical or pneumatic power is not feasible, self-operated valves are advantageous.

Pneumatic Control Valve: Can be installed in a variety of orientations and piping configurations. Design considerations revolve around accessibility, signal cabling, and air line routing.

Self-Operated Control Valve: Requires more careful installation based on pressure sensing points. For example, in steam pipelines, the actuator is typically installed downward with a condenser between the actuator and steam pipe. This protects the diaphragm from high temperatures. For gases, pressure taps are taken from the top of the pipe to ensure gas phase measurement.

Verdict: Pneumatic valves are more versatile in installation, while self-operated valves require specific layouts to function correctly and safely.

Pneumatic Control Valve Applications:

Chemical and petrochemical plants

Power generation (boilers, turbines)

Water treatment and distribution

HVAC systems with centralized control

Industrial automation and process control loops

Self-Operated Control Valve Applications:

Pressure-reducing stations

Steam supply to heating units

Lubrication systems

Gas pipelines with limited infrastructure

Remote installations without power

Choose a Pneumatic Control Valve if:

You need high accuracy and responsiveness.

Your plant has an established automation infrastructure.

Remote monitoring and control are required.

The process parameters change frequently.

The medium has demanding characteristics (high viscosity, corrosion, etc.)

Choose a Self-Operated Control Valve if:

The process is relatively stable and doesn't need frequent adjustment.

There's no power or air supply available.

You need a low-cost, low-maintenance solution.

The valve will be installed in a remote or hard-to-access area.

Control requirements are basic and local-only.

|

Feature |

Pneumatic Control Valve |

Self-Operated Control Valve |

|

Power Source |

External (Compressed air + Signal) |

Internal (Medium’s own pressure/temperature) |

|

Accuracy |

High (±0.3% to 0.5%) |

Low (±5% to 10%) |

|

Control Signal |

Remote (from DCS/PLC) |

Local only |

|

Adjustment |

Dynamic and remote |

Manual and on-site |

|

Complexity |

Higher |

Simpler |

|

Installation |

Requires air/signal lines |

Minimal infrastructure |

|

Maintenance |

Regular service needed |

Low maintenance |

|

Applications |

Precision flow and pressure control |

Static pressure/temperature regulation |

Both pneumatic control valves and self-operated control valves serve critical roles in fluid control systems but are tailored to different operational needs. Pneumatic valves bring precision, flexibility, and responsiveness, making them ideal for dynamic, automated environments. In contrast, self-operated valves offer simplicity, cost-efficiency, and autonomy, particularly beneficial in stable, low-maintenance applications.

When selecting a valve for your system, it’s important to consider factors such as control requirements, infrastructure availability, process variability, and installation conditions. By aligning valve selection with the operational demands of your process, you can achieve optimal performance, safety, and efficiency in your system.