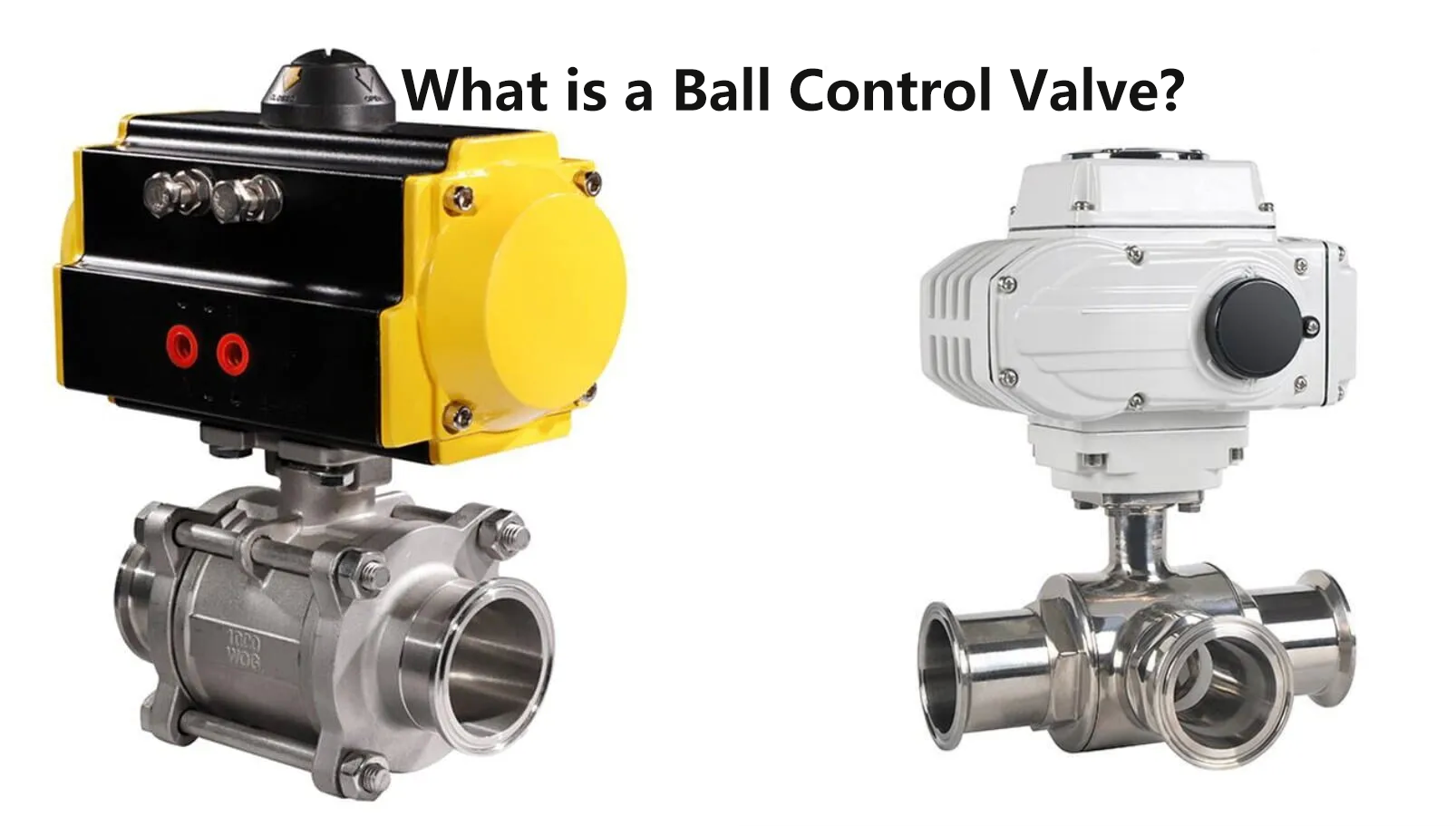

What is a Ball Control Valve?

On this page

In the expansive realm of industrial equipment, ball control valves distinguish themselves as a dependable and versatile solution for exacting flow regulation. Their ability to achieve a secure shut-off, alongside minimal maintenance demands and adaptability to a wide spectrum of temperatures and pressures, renders them indispensable across diverse industries such as oil and gas, water treatment, chemical processing, and HVAC systems.

Fundamentally, a ball control valve comprises a spherical ball that rotates within a circular chamber. Apertures in the ball align with inlet and outlet ports, permitting fluid passage. Rotation of the ball by the operator regulates flow rate or completely halts it. This straightforward yet robust design contributes to the widespread preference for ball control valves.

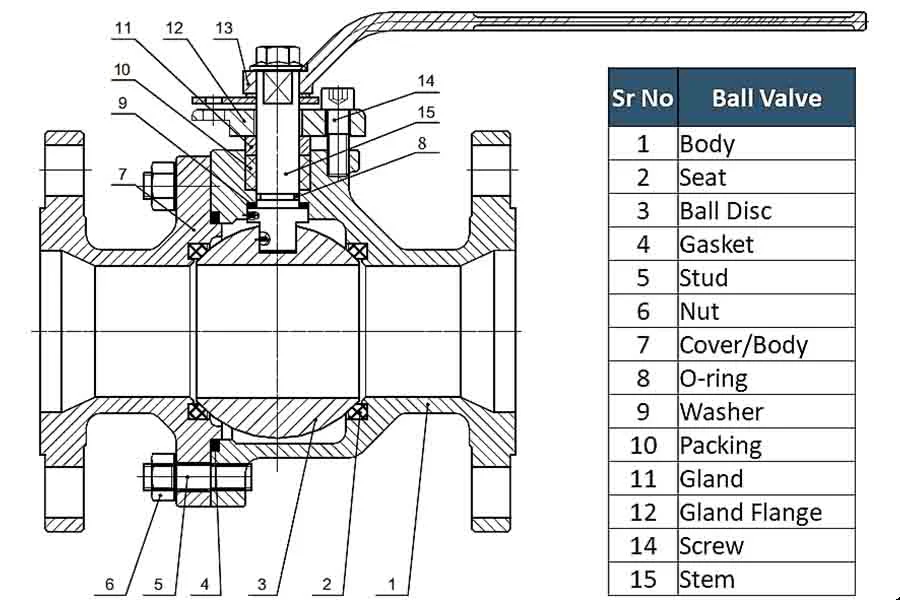

A ball control valve typically comprises several essential components, each fulfilling specific roles:

The foundational structure of a ball control valve, housing all other components and providing pathways for fluid flow when the valve is open. The design and size of the valve body vary based on application requirements and pressure conditions.

The central element of the valve, giving it its name. This spherical component contains a central port that regulates fluid flow as it rotates within the valve body. Aligning the port with the flow direction allows fluid passage, while turning it perpendicular blocks flow.

These are sealing surfaces inside the valve body against which the ball seals to prevent fluid leakage when the valve is closed. Seats are typically made from materials like Teflon-polished PTFE or elastomers, ensuring effective sealing even under high pressure conditions.

The connecting mechanism between the actuator and the ball. The stem transmits rotational motion from the actuator to the ball, facilitating its opening or closing. It is usually located at the top of the valve body and is designed to withstand external forces and ensure smooth operation.

In the expansive realm of industrial equipment, ball control valves distinguish themselves as a dependable and versatile solution for exacting flow regulation. Their ability to achieve a secure shut-off, alongside minimal maintenance demands and adaptability to a wide spectrum of temperatures and pressures, renders them indispensable across diverse industries such as oil and gas, water treatment, chemical processing, and HVAC systems.

Fundamentally, a ball control valve comprises a spherical ball that rotates within a circular chamber. Apertures in the ball align with inlet and outlet ports, permitting fluid passage. Rotation of the ball by the operator regulates flow rate or completely halts it. This straightforward yet robust design contributes to the widespread preference for ball control valves.

A ball control valve typically comprises several essential components, each fulfilling specific roles:

The foundational structure of a ball control valve, housing all other components and providing pathways for fluid flow when the valve is open. The design and size of the valve body vary based on application requirements and pressure conditions.

The central element of the valve, giving it its name. This spherical component contains a central port that regulates fluid flow as it rotates within the valve body. Aligning the port with the flow direction allows fluid passage, while turning it perpendicular blocks flow.

These are sealing surfaces inside the valve body against which the ball seals to prevent fluid leakage when the valve is closed. Seats are typically made from materials like Teflon-polished PTFE or elastomers, ensuring effective sealing even under high pressure conditions.

The connecting mechanism between the actuator and the ball. The stem transmits rotational motion from the actuator to the ball, facilitating its opening or closing. It is usually located at the top of the valve body and is designed to withstand external forces and ensure smooth operation.These components work together to provide reliable flow control and shut-off capabilities in various industrial applications.

Ball Control Valve Components

Choosing the appropriate ball control valve demands careful consideration of several factors:

Ensuring the valve is compatible with the specific fluid to prevent adverse reactions.

Verifying the valve can withstand anticipated pressures and temperatures.

Matching the valve's Cv value to the system's flow regulation needs.

Confirming compatibility with the piping system's dimensions and connections.

Selecting an actuator suitable for the application, whether manual, pneumatic, electric, or hybrid.

Assessing durability against environmental factors like corrosion and vibration.

Balancing initial investment with expected longevity and maintenance expenses.

Within the category of ball control valves, several types are commonly utilized:Basic design with a single hole in the ball aligning with inlet and outlet ports. Allows flow in two directions with dual holes in the ball for port alignment. Ball floats within the chamber, supported solely by fluid pressure. Ball supported by trunnions to prevent floating, suitable for high-pressure applications.

Trunnion Mounted Ball Valve

V-shaped hole in the ball provides precise flow control, ideal for low flow rates.

Filled with material between ball and chamber walls to reduce turbulence and enhance flow.

The primary function of a ball control valve is to regulate fluid flow within a pipeline. This is achieved through the use of a spherical component called a ball. When the ball's hole or port aligns with the flow direction, it allows fluid to pass through, effectively opening the valve. Conversely, rotating the ball so that the hole is perpendicular to the flow direction blocks fluid movement, closing the valve.In essence, a ball valve enables the initiation or cessation of fluid flow through pipelines. It offers a straightforward yet efficient method for managing various types of fluids such as liquids, gases, and slurries. These valves find application across multiple industrial sectors including oil and gas exploration and refining, water treatment facilities, chemical processing plants, HVAC systems, and more. Ball control valves play a critical role in industrial systems by ensuring precise flow control and dependable shut-off capabilities. By comprehending the diverse types available and the considerations essential for selection, engineers and operators can optimize system performance, ensuring efficiency and reliability in industrial operations.