What is Single Seated Control Valve?

On this page

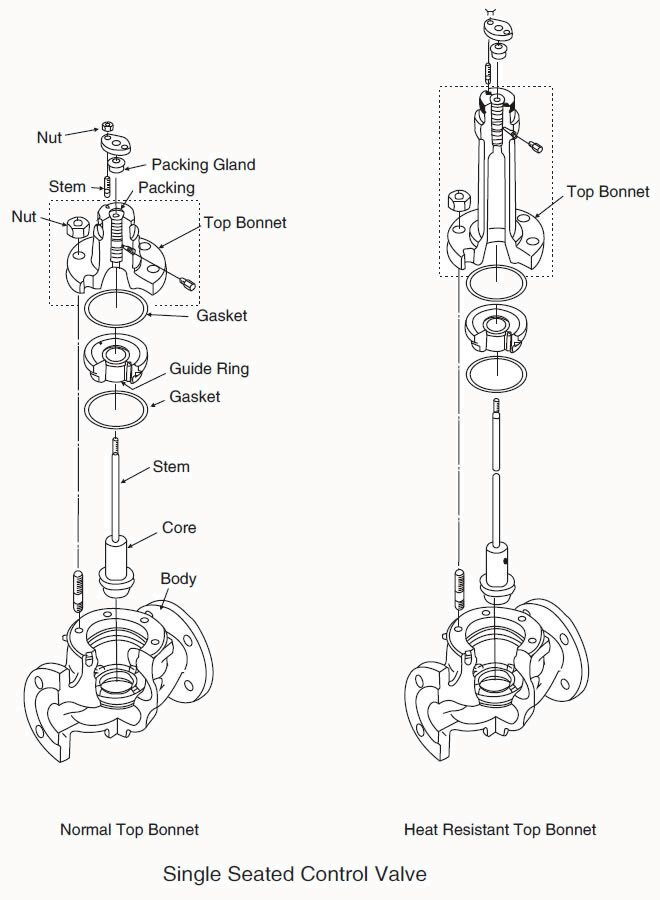

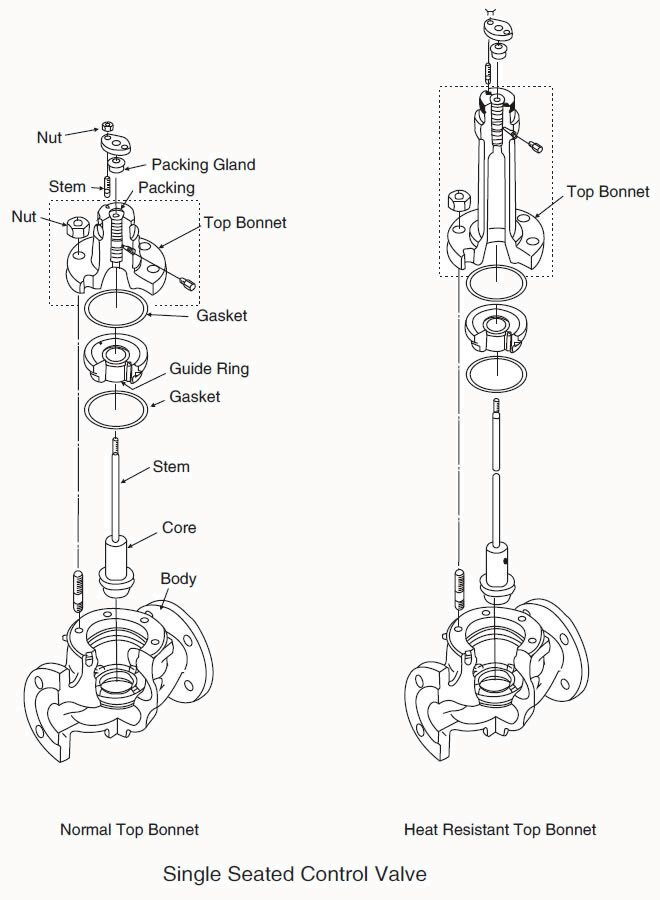

Single-port/single-seated control valves are pivotal components in industrial processes, designed to ensure precise flow control and reliable shut-off across a wide range of applications. Engineered for heavy-duty service, these control valves boast a compact valve body featuring an S-shaped flow passage that minimizes pressure loss while optimizing flow capacity, rangeability, and flow characteristics. Supported by a robust top guide section, the valve plug exhibits exceptional vibration resistance, meeting stringent IEC or JIS Standards for flow shut-off performance. Integrated with a diaphragm actuator and multiple springs, these valves excel in both high and low-temperature, high-pressure environments, making them indispensable in diverse industrial settings.

Single-port control valves are characterized by their streamlined design, comprising a compact valve body that facilitates efficient flow management. The S-shaped flow passage within the valve body reduces pressure loss, enhancing the valve's capacity to handle large flow rates while maintaining precise control over flow characteristics. The valve plug or disc, crucial for regulating flow, is supported by a top guide section that ensures stability and minimizes vibrations, thereby promoting reliable operation and extended service life. The integrated actuator, typically a diaphragm type loaded with multiple springs, provides the necessary force for efficient valve operation across various operating conditions.

These valves find extensive application across industries requiring precise control over fluid flows. From petrochemical plants to pharmaceutical manufacturing and food processing industries, single-seated control valves play a crucial role in regulating processes involving liquids, gases, and steam. Their ability to handle a broad spectrum of flow media, coupled with robust construction materials like stainless steel or carbon steel, ensures compatibility with diverse industrial environments.

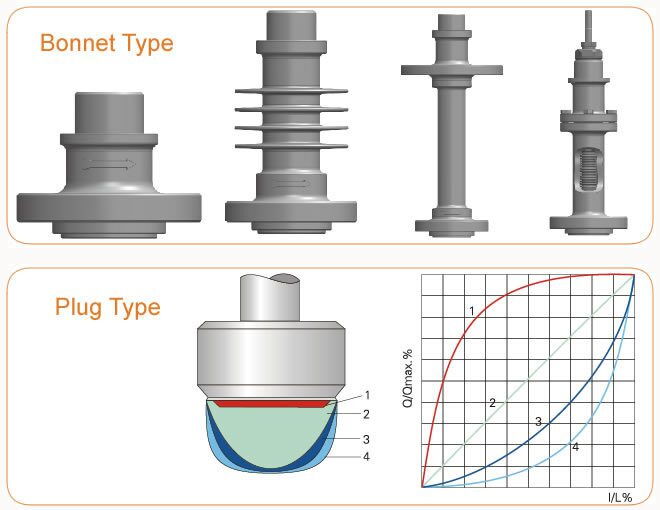

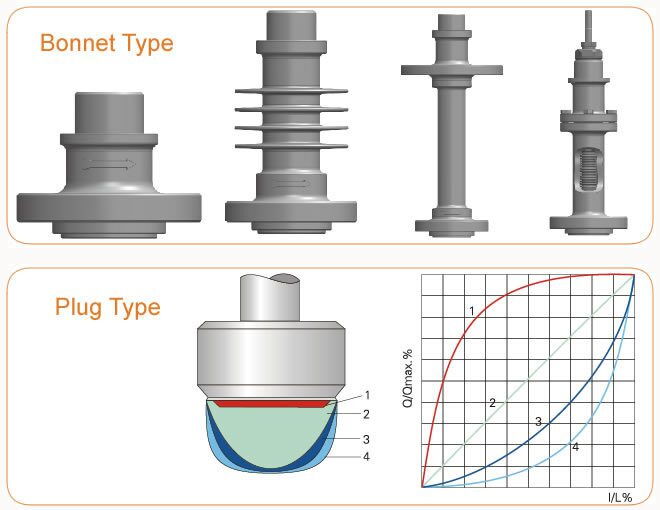

The valve offers a range of trim designs and materials to meet diverse flow capacities and characteristic requirements, including high-capacity or high-precision contoured plugs, equal percentage or linear characteristics, and options for soft or metal seats.

The inherent design of single-port control valves allows for accurate and reliable control of flow rates, crucial for maintaining process efficiency and product quality. These valves offer excellent throttling and flow modulation capabilities, enabling operators to adjust flow rates smoothly and precisely as per process requirements. Single-port control valves ensure tight shut-off when closed, preventing leakage and ensuring operational safety and efficiency. They are capable of handling a wide range of flow media including corrosive liquids, high-temperature gases, and abrasive slurries, making them versatile across different industries. With a straight-through flow path design, these valves minimize pressure drop and flow disturbances, optimizing energy efficiency and process performance. Single-seated control valves typically offer an inherent range ability of 50:1, with options available for extending this to 75:1. This range ability signifies the ratio between the maximum and minimum controllable flow rates, showcasing the valve's capability to maintain precise control across varying process conditions.

Single-port control valves represent a critical component in industrial automation and process control systems, offering unmatched precision, reliability, and versatility. With their robust design, advanced flow characteristics, and broad application range, these valves ensure optimal performance in demanding operational environments. Whether in managing high-pressure flows in petrochemical refineries or regulating precise fluid volumes in pharmaceutical production, single-port control valves continue to play a pivotal role in enhancing operational efficiency and product quality across industries globally.

Single-port control valves represent a critical component in industrial automation and process control systems, offering unmatched precision, reliability, and versatility. With their robust design, advanced flow characteristics, and broad application range, these valves ensure optimal performance in demanding operational environments. Whether in managing high-pressure flows in petrochemical refineries or regulating precise fluid volumes in pharmaceutical production, single-port control valves continue to play a pivotal role in enhancing operational efficiency and product quality across industries globally.

The inherent design of single-port control valves allows for accurate and reliable control of flow rates, crucial for maintaining process efficiency and product quality. These valves offer excellent throttling and flow modulation capabilities, enabling operators to adjust flow rates smoothly and precisely as per process requirements. Single-port control valves ensure tight shut-off when closed, preventing leakage and ensuring operational safety and efficiency. They are capable of handling a wide range of flow media including corrosive liquids, high-temperature gases, and abrasive slurries, making them versatile across different industries. With a straight-through flow path design, these valves minimize pressure drop and flow disturbances, optimizing energy efficiency and process performance. Single-seated control valves typically offer an inherent range ability of 50:1, with options available for extending this to 75:1. This range ability signifies the ratio between the maximum and minimum controllable flow rates, showcasing the valve's capability to maintain precise control across varying process conditions.

Single-port control valves represent a critical component in industrial automation and process control systems, offering unmatched precision, reliability, and versatility. With their robust design, advanced flow characteristics, and broad application range, these valves ensure optimal performance in demanding operational environments. Whether in managing high-pressure flows in petrochemical refineries or regulating precise fluid volumes in pharmaceutical production, single-port control valves continue to play a pivotal role in enhancing operational efficiency and product quality across industries globally.

Single-port control valves represent a critical component in industrial automation and process control systems, offering unmatched precision, reliability, and versatility. With their robust design, advanced flow characteristics, and broad application range, these valves ensure optimal performance in demanding operational environments. Whether in managing high-pressure flows in petrochemical refineries or regulating precise fluid volumes in pharmaceutical production, single-port control valves continue to play a pivotal role in enhancing operational efficiency and product quality across industries globally.

Pneumatic Single-Seated Control Valve

Single Seated Globe Control Valve

Single Seated Globe Control Valve

Single Seated Globe Control Valve

Single Seated Globe Control Valve