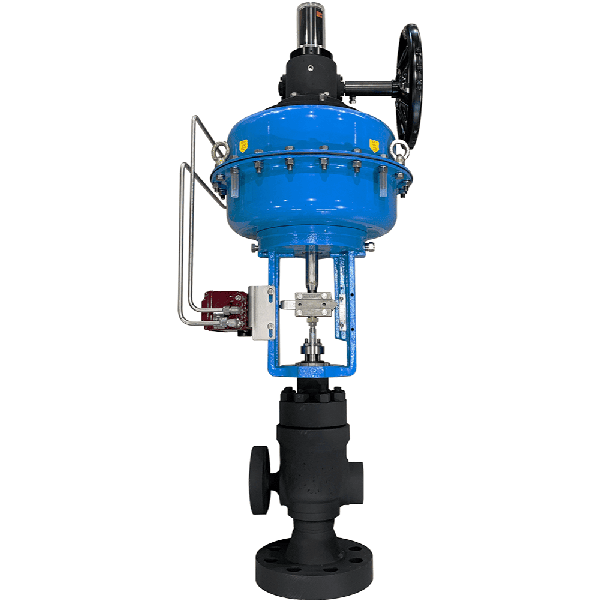

In the ever-evolving field of industrial process control, selecting the right valve for high-pressure, high-temperature, and high-differential pressure applications is crucial. One of the most advanced solutions for these demanding conditions is the Angle Type Cage-Guided Control Valve. Engineered to handle a variety of clean liquids and gases, this valve is particularly effective in severe service environments where precision, durability, and noise reduction are key considerations.

Designed with a unique cage-guided structure, this control valve provides superior stability and performance, even under extreme conditions. It effectively manages process control challenges such as cavitation, erosion, noise, and vibration, ensuring smooth operations in industries like power generation, petrochemical, oil & gas, and chemical processing.

Its ability to operate in flow-to-open (FTO) or flow-to-close (FTC) configurations makes it a versatile solution for controlling steam, gas, and liquid flow. Typically, flow-to-close trims are used in liquid applications, while flow-to-open trims are ideal for steam and gas services. This adaptability, coupled with a drilled-hole cage for anti-cavitation and low-noise performance, positions the Angle Type Cage-Guided Control Valve as an indispensable tool for industries requiring precise flow control under high-stress conditions.

At the core of the Angle Type Cage-Guided Control Valve is its cage-guided design, which significantly enhances the valve’s stability and performance. Unlike stem-guided control valves, where the plug is more susceptible to vibration and misalignment, cage-guided valves ensure the plug remains centered, reducing wear and extending service life.

This design also offers superior flow characteristics, providing efficient and predictable flow modulation across varying operating conditions. Additionally, the cage's drilled-hole design minimizes noise and vibration, which are common issues in high-pressure and high-velocity applications.

One of the standout features of this valve is its ability to accommodate different trim types, allowing it to be tailored to specific applications. The trim configurations include:

Single P-Port Trim: Suitable for general control applications, providing balanced flow regulation.

Multi-Step Trim: Designed for severe service applications where pressure drop needs to be gradually reduced to prevent cavitation and flashing.

V-Notch Cage Trim: Offers precise flow control, particularly beneficial in applications requiring fine modulation.

Flashing Service Trim: Optimized for handling flashing liquids to minimize damage to internal components.

These options make the valve highly adaptable, whether for boiler blowdown, steam conditioning, or heater drain applications.

Flashing and cavitation are major concerns in severe service applications, leading to rapid valve degradation, noise, and vibration. This control valve addresses these issues by:

Utilizing multi-stage pressure drop trim designs, preventing the sudden formation of vapor bubbles.

Incorporating hardened materials that withstand erosion from flashing fluids.

Employing noise and vibration control strategies, ensuring long-term reliability in harsh environments.

The result is a robust valve that significantly reduces wear and extends service life, making it a cost-effective choice for severe service applications.

This control valve is packed with features that make it one of the best options for handling severe process conditions:

The valve’s multi-spring diaphragm actuator minimizes hysteresis and dead band, ensuring accurate positioning and precise flow control.

It supports diaphragm, piston, hydraulic, and electric actuators, making it suitable for a wide range of automation systems.

Depending on the process safety requirements, the valve can be configured to:

Fail-Closed (FC) – Shuts off upon air supply failure.

Fail-Open (FO) – Opens upon air supply failure.

Fail-in-Place (FIP) – Holds its last position during failure.

Maintenance is simplified with a top-entry design, allowing easy removal of the bonnet and cage for internal component inspection and replacement.

The valve is available in different shutoff classes, ranging from ANSI Class IV to Class VI, allowing it to meet varying leakage rate requirements.

The drilled-hole cage effectively reduces noise and vibration, providing quiet and stable operation in high-pressure gas and steam applications.

The use of hardened trim materials and multi-stage pressure reduction designs significantly reduces wear, ensuring longer service life in extreme environments.

The top-entry design allows for rapid maintenance, reducing downtime and improving overall system efficiency.

By preventing cavitation and minimizing noise, this valve reduces energy losses, leading to lower operating costs and improved process efficiency.

The low-noise trim technology ensures quiet operation, reducing the need for additional noise-dampening equipment.

Its ability to handle high-pressure differentials, aggressive fluids, and extreme temperatures makes it suitable for:

Power plants

Petrochemical refineries

Chemical processing facilities

Oil & gas production

This control valve is ideal for a range of demanding industrial applications:

Reduces flashing and erosion damage.

Extends equipment lifespan.

Handles high-temperature condensate with minimal wear.

Prevents excessive fluid turbulence and erosion.

Offers precise modulation to maintain optimal process conditions.

Reduces noise and vibration in high-pressure steam applications.

Provides accurate control in high-differential pressure conditions.

Prevents cavitation-related damage in corrosive fluid handling.

One of the primary advantages of the Angle Type Cage-Guided Control Valve is its ease of maintenance. Key aspects include:

Unlike traditional control valves that require complete disassembly, this valve’s top-entry design enables quick access to trim components.

A simple cage change allows switching between different flow characteristics.

Linear and equal percentage trims can be swapped without replacing the entire valve.

Modular parts make it easier to keep spare components on hand.

Routine maintenance can be completed in a matter of hours rather than days.

The Angle Type Cage-Guided Control Valve offers a variety of accessories and customization options to meet specific industry needs:

Pneumatic or electric actuators for automated control systems.

Hydraulic actuators for high-force applications.

Digital positioners for real-time feedback and optimization.

Integrated smart controllers for automated process adjustments.

Additional silencers and diffusers can be used to further mitigate noise.

Corrosion-resistant alloys for harsh chemical environments.

Custom seating materials to handle aggressive fluids.

The Angle Type Cage-Guided Control Valve represents a significant advancement in process control technology, offering unparalleled stability, precision, and durability for severe service applications. Its robust design, anti-cavitation features, and noise-reducing capabilities make it an indispensable solution for industries dealing with high-pressure differentials, flashing liquids, and erosive media.

With its easy maintenance, quick trim change capabilities, and wide range of customization options, this valve provides a cost-effective, long-term solution for optimizing process control and enhancing operational efficiency.

In an era where industries demand higher reliability, lower downtime, and better energy efficiency, the Angle Type Cage-Guided Control Valve stands out as a true game-changer in severe service applications.