Control Valve Flow Characteristics

On this page

Choosing the right valve involves considering its flow characteristic, which defines how valve opening affects flow capacity—a crucial factor alongside valve size selection. Control valves typically exhibit two characteristics: inherent, which is inherent to the valve design, and installed, influenced by its installation and piping system.

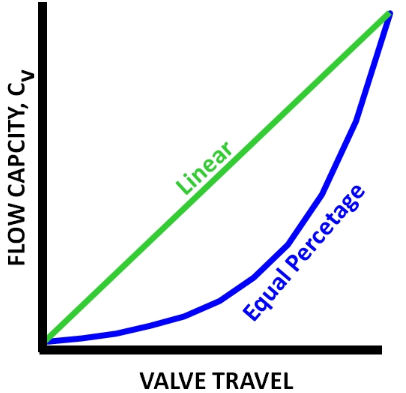

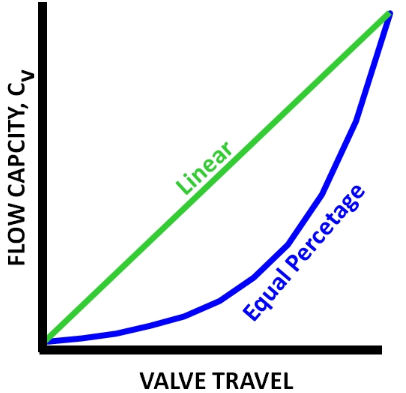

The inherent characteristic of a valve is defined by the manufacturer based on tests conducted under controlled conditions where the pressure drop across the valve remains constant across all openings and flow rates. It illustrates the direct relationship between valve flow capacity and opening without external system influences. Figure 1 illustrates the ideal linear and equal percentage characteristics. The linear characteristic derives its name from its straight-line representation on the graph.

In contrast, the equal percentage characteristic reflects that equal changes in valve position produce proportional percentage changes in flow. As depicted in Figure 1, this characteristic shows that small adjustments in valve position at lower openings result in minor flow increases, whereas the same adjustments at larger openings lead to more significant flow capacity increases.

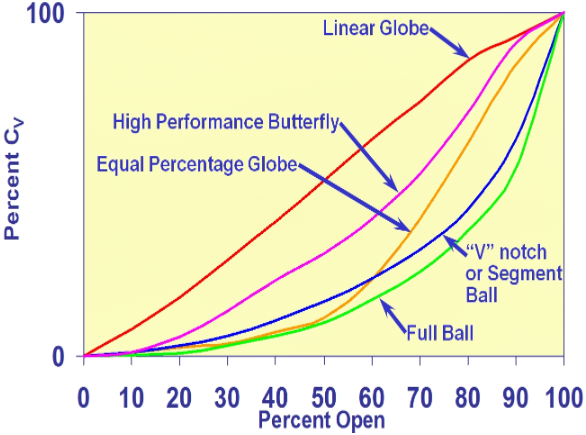

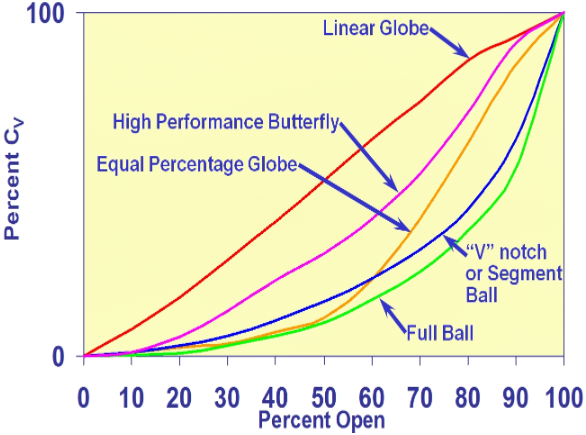

Globe valves offer versatility with either linear or equal percentage inherent characteristics, a feature not commonly found in rotary valves. Most globe control valves can switch between linear and equal percentage characteristics by simply changing the trim. Ball valves, including full ball and segmented ball types, demonstrate an almost perfect equal percentage inherent characteristic, surpassing many globe valves. High-performance butterfly valves exhibit an inherent characteristic that falls between equal percentage and linear.

Figure 2. Typical Actual Inherent Characteristics of Common Control Valve Types

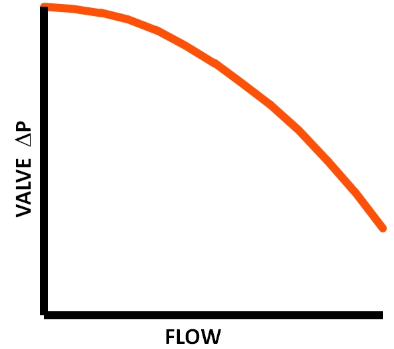

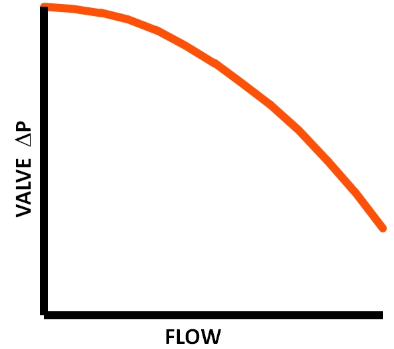

While linear behavior often optimizes control system performance, the preference for equal percentage valves arises from their installed characteristic. This characteristic reflects the specific system's relationship between valve position and flow, accounting for factors such as pressure differentials affected by flow dynamics and equipment like centrifugal pump head curves or piping losses. Many process systems incorporate extensive piping and various fittings, which affect flow and create a relationship similar to that depicted in Figure 3.

Figure 3. Valve Pressure Drop vs. Flow in a Typical System with a Significant Amount of Pipe

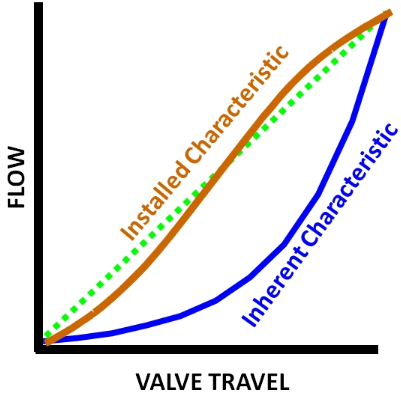

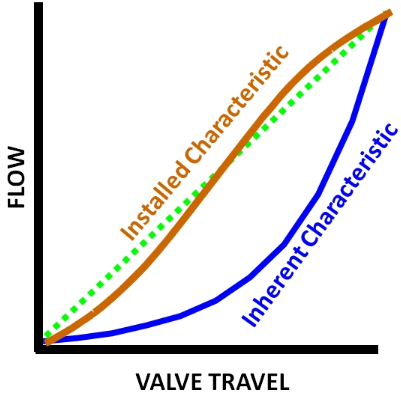

Referring to Figure 4, envision a control valve with an inherent equal percentage characteristic installed in a system resembling Figure 3. When fully open, the valve allows maximum flow. Closing the valve reduces flow, with Figure 3 indicating that as flow decreases, the pressure drop across the valve tends to rise, counteracting the flow reduction. This interaction results in a nearly linear installed characteristic.

Figure 4. Installed Characteristic of an Equal Percentage Valve in the System of Figure 3

Systems with extensive piping and fittings typically benefit from equal percentage inherent characteristic valves. Conversely, systems with minimal piping, where the pressure drop remains relatively constant, are best suited for linear inherent characteristic valves. Certain control valve sizing software can accurately plot the installed flow characteristic based on manufacturer data and specific process conditions.

When control valves are integrated with pumps and piping, the pressure drop across the valve changes as the plug moves. The curve plotting actual flow against valve opening is called the Installed Flow Characteristic.

As the valve opens and resistance decreases, the pressure drop changes:

A linear inherent curve generally resembles a quick opening characteristic.

An equal percentage curve generally resembles a linear curve.

Figure 1. Linear and Equal Percentage Inherent Characteristics

In contrast, the equal percentage characteristic reflects that equal changes in valve position produce proportional percentage changes in flow. As depicted in Figure 1, this characteristic shows that small adjustments in valve position at lower openings result in minor flow increases, whereas the same adjustments at larger openings lead to more significant flow capacity increases.

Globe valves offer versatility with either linear or equal percentage inherent characteristics, a feature not commonly found in rotary valves. Most globe control valves can switch between linear and equal percentage characteristics by simply changing the trim. Ball valves, including full ball and segmented ball types, demonstrate an almost perfect equal percentage inherent characteristic, surpassing many globe valves. High-performance butterfly valves exhibit an inherent characteristic that falls between equal percentage and linear.

Figure 2. Typical Actual Inherent Characteristics of Common Control Valve Types

While linear behavior often optimizes control system performance, the preference for equal percentage valves arises from their installed characteristic. This characteristic reflects the specific system's relationship between valve position and flow, accounting for factors such as pressure differentials affected by flow dynamics and equipment like centrifugal pump head curves or piping losses. Many process systems incorporate extensive piping and various fittings, which affect flow and create a relationship similar to that depicted in Figure 3.

Figure 3. Valve Pressure Drop vs. Flow in a Typical System with a Significant Amount of Pipe

Referring to Figure 4, envision a control valve with an inherent equal percentage characteristic installed in a system resembling Figure 3. When fully open, the valve allows maximum flow. Closing the valve reduces flow, with Figure 3 indicating that as flow decreases, the pressure drop across the valve tends to rise, counteracting the flow reduction. This interaction results in a nearly linear installed characteristic.

Figure 4. Installed Characteristic of an Equal Percentage Valve in the System of Figure 3

When control valves are integrated with pumps and piping, the pressure drop across the valve changes as the plug moves. The curve plotting actual flow against valve opening is called the Installed Flow Characteristic.

As the valve opens and resistance decreases, the pressure drop changes:

A linear inherent curve generally resembles a quick opening characteristic.

An equal percentage curve generally resembles a linear curve.