In the evolving world of industrial automation and process control, precision and reliability continue to drive technological advancement. Among the key components that underpin safe and efficient process operations are control valves—mechanical devices that modulate fluid flow in response to signals from a controller. Within this broad category, cage guided control valves have emerged as a leading choice for demanding applications across chemicals, oil & gas, power generation, refining, water treatment, and many other industries.

In 2026, cage guided control valves are not just another instrument in the process control landscape—they represent a cornerstone technology that balances performance, durability, and operational efficiency. This comprehensive report explores their technical advantages, global market dynamics, application breakthroughs, and the trends shaping their adoption in industrial sectors worldwide.

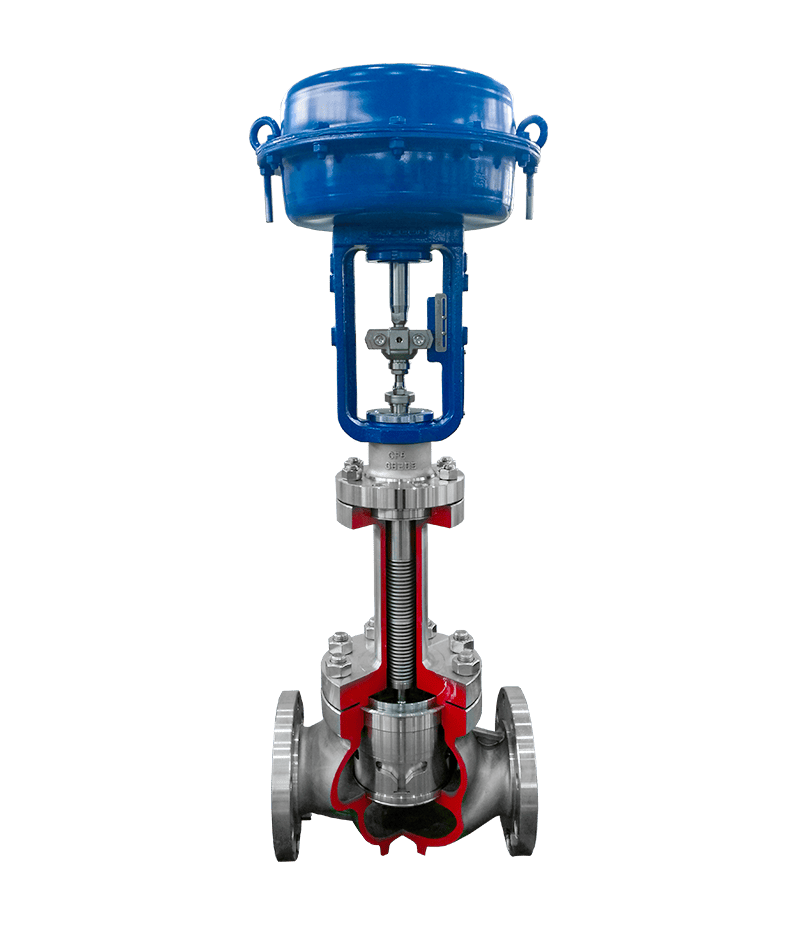

At the heart of industrial fluid regulation, control valves are designed to adjust flow rates, pressure, temperature, and fluid level by modulating the opening of a passage in a valve body. What sets cage guided control valves apart is their incorporation of a cage—a cylindrical sleeve surrounding the valve plug that guides its movement and stabilizes flow.

Unlike conventional globe valves or single-guided plug valves, the cage structure provides a controlled flow environment and tight guidance, reducing vibration, minimizing wear, and enabling accurate positioning.

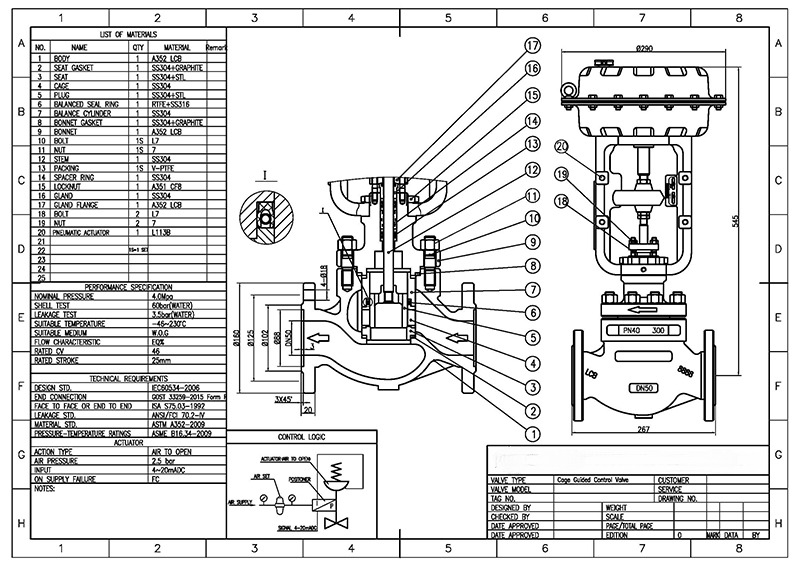

A typical cage guided control valve consists of:

- Valve Body – The main housing where fluid travels.

- Cage – A perforated cylinder with multiple ports; shapes flow and stabilizes plug motion.

- Valve Plug – The movable element that throttles flow by changing position inside the cage.

- Seat Ring – Defines sealing surface; often replaceable for maintenance.

- Actuator & Positioner – Converts control signals into mechanical motion of the plug.

The cage's internal ports are engineered to influence the flow characteristics—linear, equal percentage, or quick opening—depending on the process requirements. This controlled flow environment enhances performance across key parameters such as rangeability, stability, and repeatability.

In the dynamic world of process control, traditional valve designs sometimes struggle with issues such as vibration, cavitation, high noise, and fluctuating flow. Cage guided control valves address many of these challenges head-on.

The cage acts as a flow straightener, reducing turbulence and helping maintain laminar conditions as fluid passes through varying valve openings. This stability minimizes control loop oscillations and improves overall process accuracy.

Rangeability refers to a valve's ability to control flow effectively over a wide range of operating conditions. Cage guided valves often achieve turndown ratios of 50:1 or greater, enabling reliable performance from low throttling to full load—critical in processes where demand shifts dynamically.

By stabilizing plug motion and smoothing fluid paths, cage guided valves significantly reduce vibration—a common cause of premature wear and actuator issues. In high-velocity applications, engineered cage trims also minimize noise caused by fluid expansion and turbulence.

The guided plug motion prevents excessive lateral movement, protecting the valve seat and plug from impact and abrasion. This reduces maintenance frequency and extends operational life, offering better total cost of ownership.

Cage guided valves can be fitted with specialized trims to handle conditions such as cavitation, flashing, and erosive fluids. Engineers can choose multi-stage trims, anti-cavitation cages, or energy-dissipating designs tailored to the specific service.

The industrial demand for cage guided control valves continues to expand as sectors strive for higher throughput, stricter environmental compliance, and smarter process automation. Below are some leading application areas.

In refineries and petrochemical complexes, precise control of hydrocarbons, steam, and catalyst-laden streams is critical. Cage guided valves excel in managing high pressures and temperatures, delivering reliable flow control in crude distillation units, hydrocrackers, and reformers.

With global tolerances tightening on emissions and energy usage, refiners increasingly deploy advanced control valves along with digital diagnostics to reduce flaring, control reactor feed rates, and improve heat exchanger efficiency.

Steam control in power plants—whether fossil fuel, nuclear, or biomass—requires valves that can withstand high thermal stress while maintaining stable control. Cage guided valves with robust trims are preferred for turbine bypass, desuperheaters, boiler feedwater, and turbine inlet control services.

In combined cycle plants, precise valve control directly impacts heat rate, plant efficiency, and cycling capabilities during load changes.

Chemical plants often handle aggressive, corrosive, or reactive fluids. Cage guided control valves with corrosion-resistant trims and body materials maintain tight shutoff and durable performance in acid, solvent, and high-temperature environments.

Their ability to manage a wide range of flows helps avoid process upsets and ensures product quality.

In municipal and industrial water systems, flow control governs chemical dosing, filtration backwash, and distribution pressure. Cage guided valves offer accurate modulation with minimal cavitation—a benefit in large-diameter pipelines and variable demand cycles.

Advanced coatings and trim materials provide long service life in abrasive or particulate-laden streams.

In pipelines, compressors, and processing facilities, operators need valves that can throttle high velocities and varying pressures. Cage guided valves with anti-cavitation and high-performance trims ensure stable operation in high-pressure gas, liquid hydrocarbon, and multiphase flows.

Digital integration enables real-time diagnostics, predictive maintenance, and remote control across vast pipeline networks.

As industries adopt Industry 4.0 strategies and digital transformation accelerates, cage guided control valves are evolving with cutting-edge features.

Modern valve positioners equipped with smart sensors provide detailed performance feedback—such as travel history, friction trends, and response time. When combined with analytics software, this data predicts maintenance needs before failure, reducing downtime and unscheduled outages.

Digital twins of control valves allow simulation of performance under varying conditions, enabling engineers to optimize tuning and anticipate lifecycle events.

Materials science breakthroughs have expanded the options for trims that resist wear, corrosion, and abrasion. Ceramic composites, hardened alloys, and advanced coatings extend service life in harsh environments and reduce replacement costs.

Engineers now select trim materials not just for compatibility but for long-term performance outcomes tied to specific process profiles.

New cage geometries and multi-stage trims focus on dissipating energy in controlled steps, reducing cavitation risk and noise generation. These designs are especially valuable in high pressure drop applications like pressure letdown services.

Noise attenuating trims protect personnel and prevent damage to nearby instrumentation.

Manufacturers are offering modular cage guided valves that simplify maintenance and allow trim upgrades without full valve replacement. Retrofit kits enable older installations to achieve modern performance standards with minimal piping work.

This modularity supports sustainability goals by extending existing asset value.

Industry analysts project that the global control valve market will continue growing robustly through the mid-2020s, driven by industrial modernization, stringent environmental standards, and increased automation investment. Within this segment, cage guided valves are positioned for above-average growth due to their performance benefits.

Rapid industrialization in Asia Pacific countries—especially China, India, and Southeast Asia—has fueled demand for process control hardware. Refinery expansions, chemical plant construction, and utility upgrades are significant drivers.

Investment in petrochemical clusters and LNG infrastructure underscores the need for reliable control valves capable of handling complex services.

In the United States and Canada, aging infrastructure in refining, power generation, and water utilities is driving retrofit projects. Digital transformation initiatives favor smart valve solutions that integrate with plant automation systems.

Environmental compliance requirements are encouraging the replacement of outdated throttling valves with more precise, lower-emission alternatives.

European industries are focused on energy efficiency, decarbonization, and sustainability. Control valves that optimize flow, minimize energy waste, and support predictive maintenance align with these goals.

In renewable energy sectors—e.g., biomass plants and hydrogen production—cage guided valves are gaining traction for their stable control under variable loads.

Oil & gas investments in the Middle East continue to expand, with large downstream facilities on the drawing board. Cage guided valves are integral in high-capacity petroleum refining and petrochemical operations.

Gas processing and desalination plants in Gulf Cooperation Council (GCC) countries also contribute to regional demand.

Despite their advantages, successful deployment of cage guided control valves depends on thoughtful engineering and application awareness.

Like all control valves, poor sizing or improper trim choice can lead to performance issues such as inappropriate flow characteristics, accelerated wear, or instability. Engineers must evaluate fluid properties, pressure differentials, and process dynamics during design.

Dynamic simulation tools and experienced valve engineers are critical to optimal selection.

High pressure drops can cause liquids to vaporize and collapse, damaging valve internals. Specialized anti-cavitation cages or multi-stage energy dissipation trims are necessary for these conditions.

Flash recovery and vibration reduction should be evaluated in detailed flow assessments.

Smart positioners and diagnostics offer benefits only if integrated effectively with plant control systems. Compatibility with communication protocols (e.g., Foundation Fieldbus, HART, Modbus) and secure network architecture are essential.

Training operators and maintenance personnel in digital tools ensures full utilization of diagnostics and predictive insights.

As industries push toward net-zero targets and circular economy principles, control equipment like cage guided valves plays a supporting yet vital role. By improving process efficiency, reducing energy waste, and enabling smarter automation, these valves contribute indirectly to sustainability goals.

Emerging applications such as hydrogen blending in gas networks, carbon capture and storage (CCS), and advanced chemical recycling will place new demands on flow control technologies. Cage guided designs, with their adaptability and performance, are positioned to address many of these needs.

In 2026, cage guided control valves are more than a product—they are a strategic asset that enables industries to achieve precise flow control, lower operational costs, and enhanced safety. Their continued evolution—driven by digital integration, advanced materials, and engineering innovation—positions them at the forefront of modern process control.

As global industries navigate volatility, energy transitions, and complex regulatory landscapes, the choice of core components such as control valves will increasingly distinguish leaders from laggards. Cage guided control valves, with their blend of performance, reliability, and flexibility, are likely to remain a key enabler of industrial excellence in the years ahead.