As global industries continue to pursue higher energy efficiency, automation, and operational stability, precise temperature control has become a foundational requirement across heating, cooling, and industrial process systems. Whether in district heating networks, HVAC installations, chemical processing plants, or power generation facilities, maintaining stable and accurate temperature conditions directly influences energy consumption, system safety, and overall performance.

The electric temperature control valve plays a crucial role in achieving these objectives. By combining advanced electric actuators, intelligent controllers, and accurate temperature sensing technology, electric temperature control valves provide automatic, continuous, and precise regulation of fluid temperature. Compared with traditional manual valves or purely mechanical thermostatic valves, electric temperature control valves offer faster response, higher accuracy, and seamless integration with modern automation systems.

With the rapid development of smart buildings and industrial digitalization, electric temperature control valves have become indispensable components in both building automation systems (BAS) and industrial control systems. This article explores the principles, structure, control characteristics, actuator technologies, application fields, and performance advantages of electric temperature control valves in detail.

An electric temperature control valve is a type of regulating valve designed to control fluid temperature by adjusting the valve opening degree through an electric actuator. Its primary function is to automatically regulate fluid flow or the mixing ratio of hot and cold media based on temperature feedback signals.

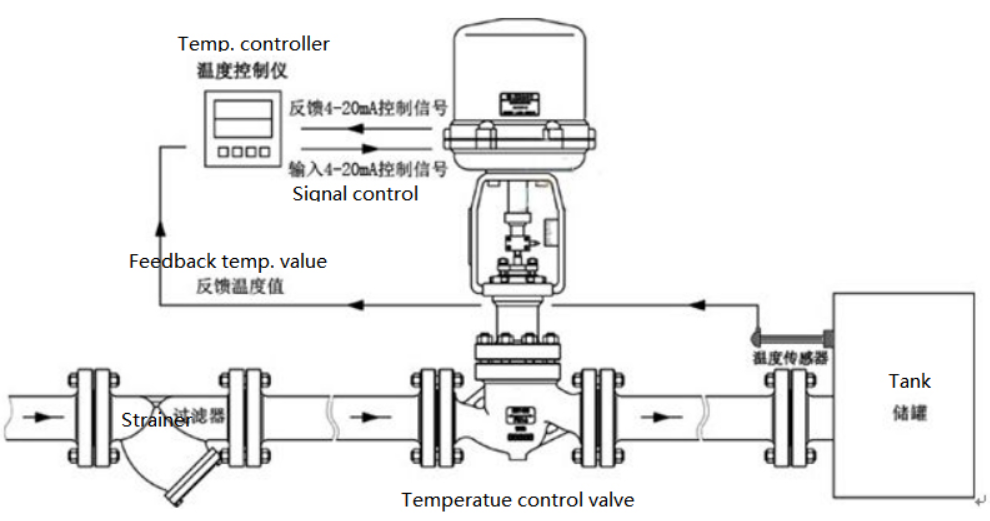

The valve receives temperature signals from sensors installed at critical points in the system, such as supply pipes, return pipes, or heat exchange outlets. The controller compares the measured temperature with a predefined set value and calculates the necessary adjustment. The electric actuator then drives the valve to the appropriate position, ensuring that the system temperature remains stable and within the desired range.

Electric temperature control valves are widely used in:

District and city heating systems

Gas and thermal energy distribution networks

Central air conditioning and refrigeration systems

Building automation and energy management systems

In industrial sectors, they are essential components in automatic process control systems for:

Chemical and petrochemical plants

Petroleum and gas industries

Mining and metallurgical operations

Power generation facilities

Food and beverage processing

Pharmaceutical manufacturing

Electric temperature control valves operate based on a closed-loop control principle, which allows continuous monitoring and automatic correction of temperature deviations.

Temperature sensors measure the real-time temperature of the controlled medium or environment. These sensors convert temperature data into electrical signals and transmit them to the controller.

The controller processes the incoming signal and compares it with the preset target temperature. Based on the difference between actual and target values, the controller applies control algorithms—such as PI (Proportional-Integral) or PID (Proportional-Integral-Derivative)—to calculate the required adjustment.

The electric actuator receives the control signal and converts it into mechanical motion, adjusting the valve opening degree. This regulates the flow rate or mixing proportion of fluids.

As the valve position changes, the system temperature gradually approaches the set value. Continuous feedback ensures that the valve responds dynamically to load changes, maintaining temperature stability.

This automatic control process eliminates manual intervention, reduces energy waste, and improves overall system efficiency.

The valve body is the primary flow component and must withstand operating pressure, temperature, and fluid characteristics. Depending on application requirements, valve bodies may be manufactured from:

Carbon steel

Stainless steel

Ductile iron

Alloy steel

Electric temperature control valves are suitable for controlling a wide range of media, including:

Cooling water

Low-pressure hot water

High-pressure hot water

Salt water

Thermal oil

Steam

High-quality valve designs offer:

Excellent linearity

Wide adjustable range

Tight shut-off performance

High-temperature resistance

Strong anti-cavitation capability

These characteristics ensure stable operation even under demanding conditions.

The electric actuator is responsible for driving the valve and is a critical factor in overall performance. Two main actuator types are commonly used.

Electro-mechanical actuators convert electrical energy directly into mechanical motion through gears and motors. Their key advantages include:

High positioning accuracy

Low energy consumption

Compact structure

Simple installation and maintenance

These actuators are widely used in HVAC systems and building automation applications.

Electro-hydraulic actuators combine electrical control with hydraulic force generation. They are especially suitable for large valves and high-pressure systems. Key benefits include:

High output force and torque

Smooth and stable movement

Fast response time

Strong adaptability to harsh industrial environments

Electro-hydraulic actuators often feature automatic reset functions and enhanced safety mechanisms.

Electric temperature control valves support standard industrial control signals, such as:

0–10 V

4–20 mA

These signals ensure compatibility with programmable logic controllers (PLC), distributed control systems (DCS), and building management systems (BMS).

Modern controllers provide advanced functions, including:

PI and PID regulation

Multi-loop control capability

Monitoring and control of flow, pressure, differential pressure, temperature, humidity, enthalpy, and air quality

Communication via Modbus, BACnet, or other protocols

Such intelligent control enables precise regulation, real-time monitoring, and remote management.

Many electro-hydraulic actuators are equipped with automatic power failure reset protection. In the event of a power outage, the valve automatically moves to a predefined safe position, such as fully open or fully closed, ensuring system safety and preventing equipment damage.

Position feedback signals provide real-time information on valve opening status. This feature improves control accuracy, supports fault diagnosis, and enhances overall system transparency.

Relative flow (G/Gmax) represents the ratio between the flow at a given valve opening and the maximum flow when fully open.

Relative stroke (l) refers to the ratio of the current valve stroke to the full stroke.

The relationship between relative flow and relative stroke defines the flow characteristic of the valve and is expressed as:

G/Gmax = f(l)

Electric temperature control valves can be designed with various flow characteristics, including:

Linear

Fast-opening

Equal percentage

Parabolic

Each characteristic is suitable for different control scenarios.

In heating systems, especially radiator-based systems, the relationship between heat output and flow rate is inherently non-linear. As flow increases, heat output rises rapidly at first and then gradually approaches saturation.

From both hydraulic stability and thermal regulation perspectives, this behavior forms an upward parabolic curve. To compensate for this non-linearity, equal percentage flow characteristics are commonly adopted.

Advantages include:

Improved system stability

Better temperature regulation accuracy

Reduced control oscillation

Easier system commissioning

As a result, equal percentage electric temperature control valves are widely used in heating and cooling applications.

Electric temperature control valves regulate the flow of hot or chilled water in district energy networks, ensuring stable indoor temperatures while reducing energy losses.

In central air conditioning systems, these valves precisely control chilled water and hot water flows, enabling demand-based temperature regulation and significant energy savings.

In chemical, petrochemical, and power generation industries, accurate temperature control is essential for process efficiency and safety. Electric temperature control valves ensure stable operation under high temperature and pressure conditions.

Strict temperature control is critical for product quality and regulatory compliance. Electric temperature control valves provide reliable and hygienic temperature regulation in these sensitive industries.

High temperature control precision

Fully automatic operation

Strong compatibility with automation systems

Energy-saving performance

Improved system safety

Long service life and low maintenance requirements

With the advancement of smart control technologies, electric temperature control valves are evolving toward:

Higher intelligence and digitalization

Integration with IoT platforms

Predictive maintenance capabilities

Enhanced energy efficiency

These developments will further expand their application scope and value.

Electric temperature control valves are essential components in modern thermal management systems. By combining intelligent control algorithms, reliable electric actuators, and optimized flow characteristics, they provide accurate, stable, and efficient temperature regulation across a wide range of applications.

As energy efficiency standards become stricter and automation levels continue to rise, electric temperature control valves will play an increasingly important role in building automation, industrial process control, and sustainable energy systems. Their ability to deliver precise control, reduce energy consumption, and improve operational reliability makes them a cornerstone of modern temperature regulation technology.