How to Choose Motorized Ball Control Valves?

On this page

Motorized ball control valves are pivotal components in numerous industrial and commercial applications, from HVAC systems to water treatment plants and chemical processing facilities. Selecting the right valve requires a methodical approach, considering several critical factors to ensure optimal performance and efficiency. This comprehensive guide outlines key considerations to help you navigate the selection process effectively:

Before choosing a motorized ball control valve, thoroughly assess the specific requirements of your application. Consider factors such as the type of fluid being controlled (e.g., water, chemicals, gases), operating pressure and temperature ranges, environmental conditions (e.g., indoor, outdoor, hazardous environments), and regulatory compliance. Understanding these variables ensures that the selected valve will operate reliably and efficiently within its intended environment.

Accurate sizing of motorized ball control valves is essential to achieve optimal system performance. Evaluate the required flow rate, pressure drop, and flow characteristics of your system to determine the appropriate valve size. Factors such as pipe diameter, flow coefficient (Cv or Kv), and anticipated variations in flow demand should be considered. Proper sizing not only ensures efficient fluid control but also minimizes energy consumption and operational costs.

The selection of materials for motorized ball control valves depends on the compatibility with the fluid being handled and the environmental conditions. Common materials include stainless steel, brass, bronze, and various plastics. Consider factors such as corrosion resistance, chemical compatibility, mechanical strength, and hygiene requirements (e.g., for food or pharmaceutical applications). Choosing the right materials ensures long-term durability, reliability, and safety of the valve system.

Motorized ball control valves are actuated using electric motors, offering precise and reliable control over valve operation. When selecting the actuation method, consider factors such as response time, positioning accuracy, automation capabilities, and power supply requirements. Direct-mount actuators are suitable for compact installations, while remote actuators allow for centralized control in large-scale systems. Evaluate the compatibility of the actuation method with your control system and operational needs.

Motorized ball control valves offer a range of control options to meet diverse application requirements:

Ideal for applications requiring simple open/close operations, such as start/stop functions in heating or cooling systems.

Provides continuous adjustment of the valve position to maintain a desired flow rate or pressure level. Suitable for processes requiring precise control and stability.

Offers variable positioning based on proportional input signals, ensuring accurate and responsive fluid regulation. Commonly used in applications demanding fine-tuned control and energy efficiency.

Selecting the appropriate control option depends on factors such as system complexity, performance specifications, and energy efficiency goals. Budget constraints and quality considerations are crucial when selecting motorized ball control valves. While initial costs may vary based on valve type and features, it is essential to consider long-term reliability, maintenance requirements, and energy efficiency. Investing in high-quality valves from reputable manufacturers can minimize downtime, reduce operational costs, and ensure consistent performance over the valve's lifespan. Choosing motorized ball control valves involves evaluating application requirements, selecting appropriate valve size and material, considering actuation methods and control options, and balancing budget with quality considerations. By understanding these factors and consulting with industry experts, you can make informed decisions to optimize fluid control, enhance system efficiency, and meet operational objectives in various industrial and commercial applications.

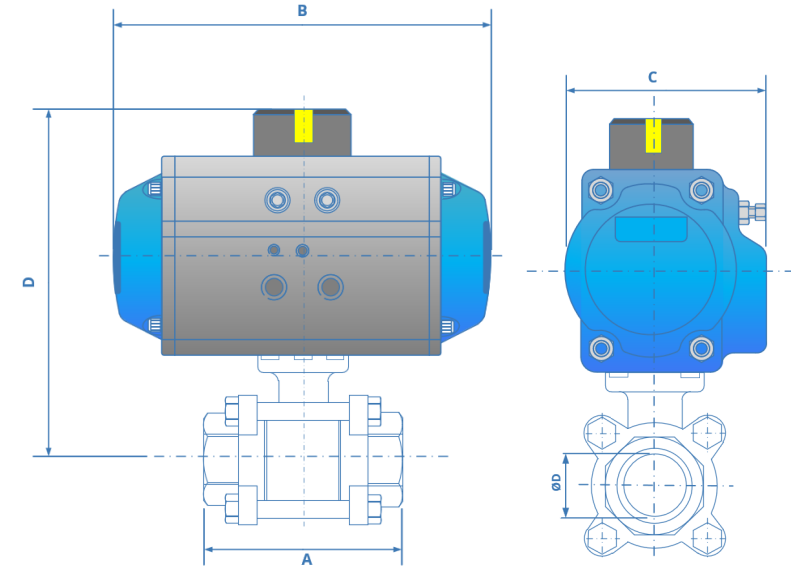

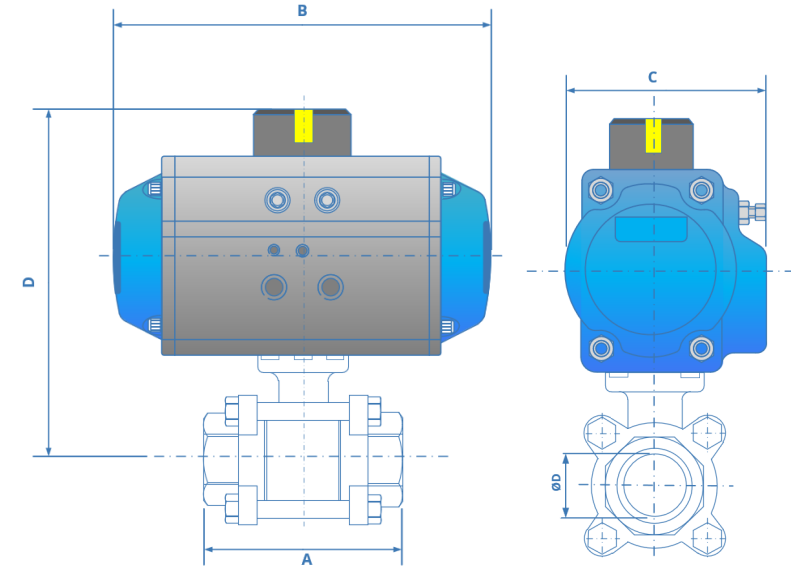

| Dimensions for Spring Return | |||||

| Valve | A | B | C | D | Weight kg |

| 1/2 Inch | 75 | 146 | 72 | 135 | 1.66 |

| 3/4 Inch | 80 | 163 | 85 | 157 | 1.99 |

| 1 Inch | 90 | 163 | 85 | 165 | 3.07 |

| 1-1/4 Inch | 110 | 252 | 96 | 188 | 5.19 |

| 1-1/2 Inch | 120 | 252 | 96 | 193.5 | 6.15 |

| 2 Inch | 140 | 270 | 108 | 214 | 8.2 |

| 2-1/2 Inch | 185 | 316 | 123 | 248 | 13.75 |

| 3 Inch | 205 | 354 | 141 | 278.5 | 21.95 |

| 4 Inch | 240 | 354 | 151 | 291.5 | 32.8 |

Selecting the appropriate control option depends on factors such as system complexity, performance specifications, and energy efficiency goals. Budget constraints and quality considerations are crucial when selecting motorized ball control valves. While initial costs may vary based on valve type and features, it is essential to consider long-term reliability, maintenance requirements, and energy efficiency. Investing in high-quality valves from reputable manufacturers can minimize downtime, reduce operational costs, and ensure consistent performance over the valve's lifespan. Choosing motorized ball control valves involves evaluating application requirements, selecting appropriate valve size and material, considering actuation methods and control options, and balancing budget with quality considerations. By understanding these factors and consulting with industry experts, you can make informed decisions to optimize fluid control, enhance system efficiency, and meet operational objectives in various industrial and commercial applications.