Motorized globe control valves play an essential role in various industries, ensuring precision control over fluid and gas flow in automated systems. These valves, equipped with electric actuators, are designed to handle a wide range of flow control tasks, making them indispensable in sectors like oil and gas, chemicals, power generation, pharmaceuticals, and agriculture. The integration of electric control systems into valves has revolutionized industrial automation, offering greater reliability, efficiency, and accuracy in managing fluid dynamics. This article delves into the working principles, key features, and considerations involved in selecting motorized globe control valves for diverse industrial applications.

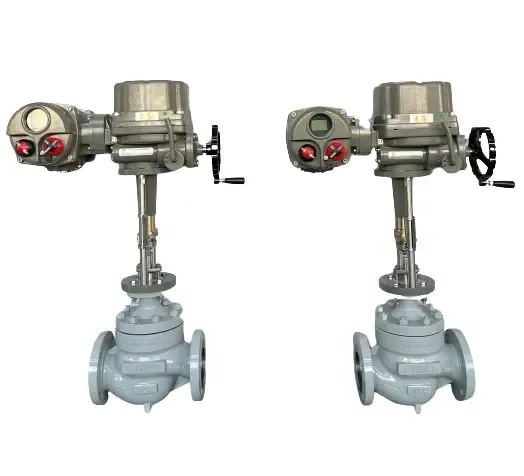

A motorized globe control valve is a type of valve that uses an electric motor to regulate the flow of fluids within a system. The valve is typically designed with a globe-shaped body, which allows for precise flow regulation and throttling. The motorized actuator controls the valve’s opening and closing, making it ideal for situations where remote or automated control is necessary.

Unlike traditional manual valves, motorized globe control valves can be integrated into complex automated systems, enabling remote operation and minimizing the need for human intervention. This feature is particularly useful in industrial settings that require continuous or real-time adjustments to fluid flow based on changing process conditions.

Motorized globe control valves are often employed in process control systems for the regulation of water, steam, oil, chemicals, and gases. They are used to control fluid flow, pressure, temperature, and other parameters, ensuring that the operation runs smoothly and efficiently.

In the oil and gas sector, motorized globe control valves are used to regulate the flow of crude oil, natural gas, and other hydrocarbons. These valves are critical in managing pressure, temperature, and flow rates during extraction, transportation, and refining processes.

In chemical plants, these valves control the flow of reactants and products through pipelines, ensuring that chemical reactions occur under optimal conditions. Motorized globe control valves can be used in systems that handle corrosive or hazardous chemicals, where precise control is essential for safety and product quality.

In power plants, motorized globe control valves regulate steam and water flow within boilers, turbines, and cooling systems. Proper flow control is vital for maintaining efficient energy generation and preventing system overloads.

Pharmaceutical manufacturing processes require strict regulation of fluid flow to maintain the integrity of products. Motorized globe control valves are used to manage the flow of liquids and gases in these critical environments, ensuring that the right conditions are maintained throughout production.

In large-scale agricultural irrigation systems, motorized globe control valves help manage water distribution, ensuring that crops receive an optimal amount of water at the right time.

These valves are also used in automated fire suppression systems, where they control the flow of water or fire retardant chemicals, quickly and precisely responding to changes in pressure and flow to suppress fires.

Motorized globe control valves consist of a globe valve body combined with an electric actuator. The actuator uses an electric motor to adjust the valve’s position, either opening or closing the valve in response to signals from a control system. The key components of a motorized globe control valve are:

Typically made from materials such as stainless steel, carbon steel, or other alloys, the body houses the internal components that regulate the flow of fluids. The globe valve body design allows for smooth and precise flow regulation, with the ability to control both the volume and pressure of the fluid.

The electric actuator is the driving force behind the valve’s movement. It converts electrical signals into mechanical movement, adjusting the position of the valve. Actuators can vary in design, ranging from simple on/off models to more sophisticated modulating actuators that provide fine control over the valve’s position.

In more advanced systems, a positioner is used to ensure that the valve reaches the exact desired position. The positioner continuously monitors the valve’s position and adjusts the actuator to maintain accuracy.

Motorized globe control valves are typically integrated into a Distributed Control System (DCS) or Programmable Logic Controller (PLC), which sends control signals to the actuator. These signals are based on feedback from sensors that monitor the relevant parameters, such as flow rate, pressure, or temperature.

The position of the valve’s plug determines the flow rate, and by adjusting this position, the actuator can control the fluid flow with high precision. The motorized actuator continuously adjusts the plug’s position in response to changes in the process conditions, providing dynamic flow control.

When selecting motorized globe control valves for a specific application, several critical parameters must be considered to ensure optimal performance:

The nominal diameter refers to the valve's inlet and outlet size and determines its flow capacity. Larger diameters are needed for higher flow rates. It's important to match the nominal diameter to the size of the piping system and the desired flow rate for optimal efficiency.

The flow coefficient (Cv) is a measure of the valve’s flow capacity. A higher Cv indicates that the valve can allow more flow for a given pressure drop. When selecting a valve, it is important to choose a valve with a Cv that matches the required flow rate and pressure conditions.

The adjustable range refers to the extent to which the valve can control flow within its rated stroke. A wider adjustable range provides greater flexibility in controlling fluid flow, which is particularly important in systems with varying flow rates.

The drive mode defines the type of actuator used to control the valve. There are three main types of actuators:

These are typically used for simple on/off control, where the valve either opens or closes fully.

These actuators offer advanced features such as remote monitoring, diagnostics, and communication with the control system.

These provide precise control by using digital signals, often employed in modulating applications where continuous adjustment is needed.

Common power supply voltages for motorized globe control valves include AC220V, AC380V, and DC24V. The choice of voltage should be compatible with the power available at the installation site.

The protection grade indicates the level of resistance the valve has against dust, water, and other environmental factors. For valves exposed to harsh environments, a higher protection grade is necessary to ensure reliability and longevity.

When choosing a motorized globe control valve, it’s important to consider the operational conditions of the system. These include the type of medium being controlled, the working pressure, and the operating temperature. Here are key factors to consider:

The type of fluid or gas passing through the valve will significantly impact the valve’s performance and material requirements. For example:

Corrosive media such as acids or chlorine gas will require valves made from corrosion-resistant materials like stainless steel or specially coated alloys.

Viscous fluids will require valves that can handle thick materials without clogging.

The working pressure affects both the design and the material selection of the valve. Valves for high-pressure systems must be constructed from stronger materials and may require specialized sealing mechanisms to ensure leak-free operation.

Temperature variations also impact valve performance. Valves handling high-temperature fluids must be constructed from heat-resistant materials, and the seals must be chosen to withstand the elevated temperatures.

If precise flow control is required, ensure that the actuator and valve design provide the necessary modulating capabilities. Smart or digital actuators offer finer control than traditional mechanical actuators.

The environmental conditions, such as exposure to dust, humidity, or chemicals, will determine the protection grade needed for the valve and actuator.

Motorized globe control valves are vital components in modern industrial automation, providing precise and reliable control of fluid and gas flow in a wide range of applications. Whether in the oil and gas industry, chemical processing, pharmaceuticals, or agriculture, these valves offer unparalleled flexibility, efficiency, and safety.

By selecting the appropriate motorized globe control valve based on key parameters like nominal diameter, flow coefficient, adjustable range, and environmental conditions, businesses can ensure that their systems run efficiently, safely, and in compliance with industry standards. These valves are integral to the smooth operation of automated systems, and their continued evolution promises even greater control and efficiency in industrial processes.