Control valves are integral components in regulating and controlling a wide array of processes across industries such as manufacturing, chemical processing, and power generation. However, in order to maintain precise control over the process variables like temperature, pressure, and flow, a control valve must be capable of quick, accurate adjustments. This is where Control Valve Positioners come into play. These devices ensure that control valves respond promptly and accurately to process demands, ensuring smooth operations and preventing fluctuations that could disrupt productivity or product quality.

A Control Valve Positioner is a device that adjusts the position of a control valve's actuator to ensure that the valve accurately reflects the desired set point for a given process variable. These variables can include temperature, pressure, or flow, and the positioner ensures that any deviation from the desired setpoint is corrected promptly.

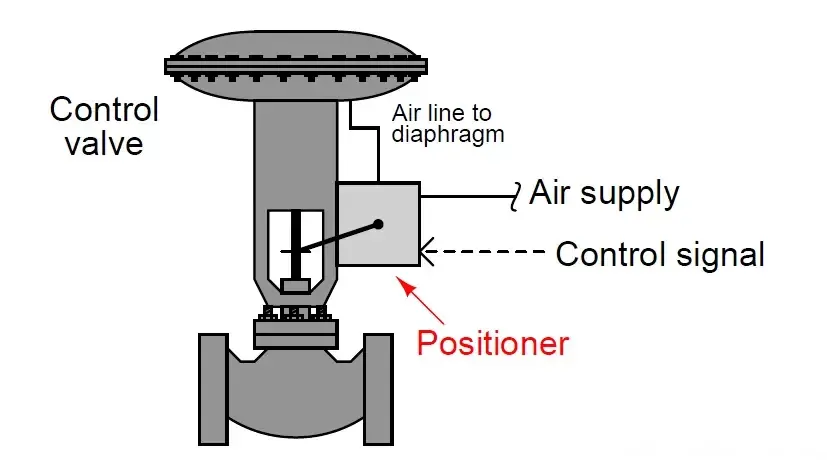

In older control systems, a process controller would send a direct signal to the diaphragm actuator, which would then adjust the valve position. While this system works, it tends to be slower and less accurate, especially since actuators often have a certain degree of offset, meaning they can only be accurate within a specified range.

For applications requiring frequent adjustments or high precision, the standard control system is often inadequate. This is where the control valve positioner becomes essential. It works by interfacing with both the process controller and the actuator, providing real-time feedback and ensuring precise control over the valve's position, which is critical for maintaining operational efficiency.

Control valve positioners are typically installed directly onto the actuator. For linear control valves, they are usually attached to the yolk or top casing of the actuator. For rotary control valves, the positioner is typically installed in-line with the valve and actuator stems, either on top of or on the side of the actuator. The specific installation method depends on the type of actuator used.

Once installed, the positioner continuously monitors the valve’s stem travel or the degree of rotation. It senses any deviation between the current valve position and the desired position as dictated by the process controller. If the process variable (e.g., pressure, temperature, or flow) differs from the set point, the controller sends either an electrical or pneumatic signal to the positioner. The positioner, in turn, adjusts its output to the actuator, moving the valve open or closed as needed until the desired set point is achieved.

By receiving input from the process controller and providing output to the actuator, the positioner ensures that the valve's position always corresponds to the required process conditions, optimizing efficiency and system performance.

Control valve positioners can be categorized into several types based on their operational principles and features. The three main types are:

The traditional valve positioner, which uses pneumatic signals to control the valve actuator. This type of positioner is often employed in simple control systems where electronic control isn't necessary.

This type of positioner converts electrical signals (usually 4-20 mA) from the controller into a pneumatic output to adjust the actuator. Electro-pneumatic positioners offer a more sophisticated level of control, integrating the precision of electrical signals with the robust action of pneumatic actuators.

A more modern solution, the digital valve positioner uses digital communication protocols, such as HART or FOUNDATION Fieldbus, to provide more precise control. It can offer advanced diagnostics, higher accuracy, and remote configuration capabilities, making it ideal for complex, high-performance systems.

While not all applications require valve positioners, many systems stand to benefit significantly from their inclusion. These advantages are especially noticeable in environments where small fluctuations in process conditions can lead to disastrous consequences for productivity, safety, or product quality. Here are the top five benefits that valve positioners provide in control valve systems:

Since valve positioners continuously measure and adjust the position of the valve, they provide much greater control accuracy than actuators alone. This becomes particularly valuable in the lower portion of the valve stroke, where errors are more likely to occur. By eliminating these inaccuracies, positioners help ensure that the system remains within optimal operating conditions.

A valve positioner ensures that control valves respond more rapidly to changes in the process variable. Whether it’s adjusting to a temperature shift, pressure fluctuation, or flow rate change, the positioner minimizes the delay between the detection of a discrepancy and the correction of the valve position, thereby reducing the time the system spends outside of the desired setpoint.

In applications where differential pressure varies, maintaining consistent valve position becomes a challenge. Varying pressure across the valve can lead to instability in the control loop, causing overshooting or erratic behavior. Positioners help stabilize the valve’s position, ensuring consistent performance despite fluctuating pressures.

Valve positioners offer enhanced flexibility in system design and configuration. They allow for the separation of the controller from the control valve, which can be beneficial in larger systems. Additionally, positioners enable the use of different actuator types, including diaphragm or piston-controlled actuators. They also allow for adjustments between direct and reverse control actions, as well as changes to flow characteristics when needed. In some systems, positioners can even control two valves with a single controller (known as split ranging).

Friction within the valve stem packing can contribute to problems such as hysteresis and deadband. These issues can cause inaccuracies in valve positioning, which leads to inefficiencies in the system. By providing precise and continuous adjustments, the positioner minimizes the impact of friction, ensuring smoother operation and reducing deadband effects.

The working principles of valve positioners vary slightly depending on whether they are electro-pneumatic (EP) or pneumatic-pneumatic (PP).

This type of positioner receives a 4-20mA input signal from the controller, which corresponds to the required valve position. The positioner converts this electrical signal into a pneumatic output (typically in the range of 3-15 psi) to adjust the actuator and move the valve accordingly.

For purely pneumatic systems, the positioner receives a pneumatic signal, usually in the range of 3-15 psi. It adjusts the actuator accordingly to control the valve position. Pneumatic systems are often employed in simpler or older control systems where electronic integration is not necessary.

The positioner acts as the intermediary between the process controller and the actuator, ensuring that any changes in the process variable are accurately reflected in the valve's position. The device continuously monitors and adjusts the valve's movement, correcting any discrepancies as needed to keep the system running smoothly and efficiently.

Control valve positioners are essential devices that enhance the precision, speed, and stability of control valve operations. They play a critical role in ensuring that industrial processes remain within their desired parameters, preventing costly errors and downtime. Whether it's improving control accuracy, responding faster to process changes, or maintaining consistent performance in fluctuating pressure conditions, valve positioners are indispensable in modern control systems.

By understanding how valve positioners work and their key benefits, industries can leverage their capabilities to optimize system performance, improve product quality, and reduce operational risks. As automation and process control continue to evolve, valve positioners will remain integral to achieving the high levels of precision required in today's fast-paced industrial environments.