Understanding Rangeability in Control Valves

On this page

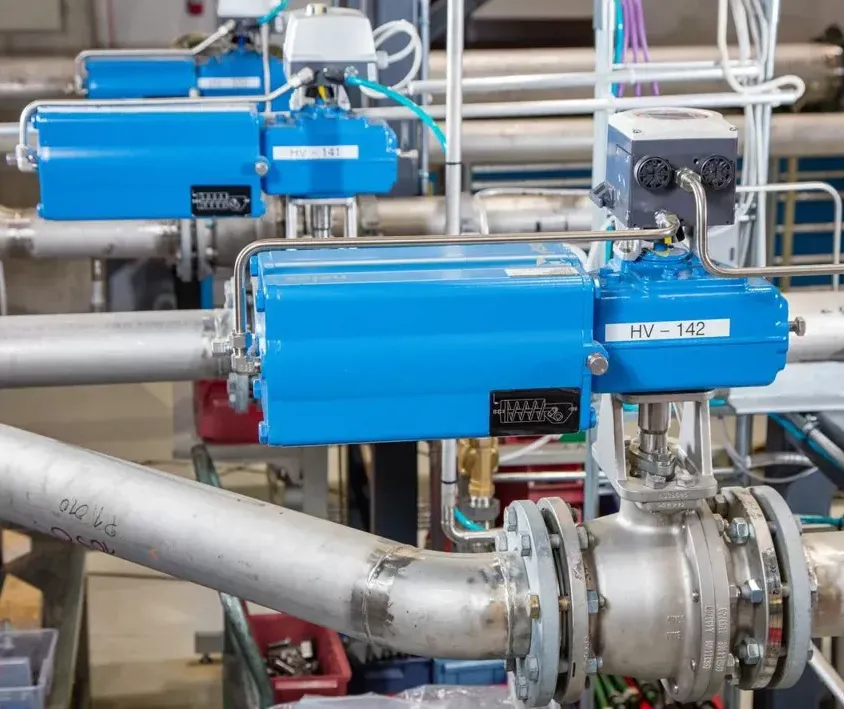

Control valves play a crucial role in regulating fluid flow within various systems, ensuring that processes operate smoothly and efficiently. One of the critical parameters for evaluating a control valve’s performance is its rangeability. While the term lacks a universally established definition, it generally describes a valve's ability to manage flow rates across a range. Understanding rangeability, including its two main types—inherent rangeability and installed rangeability—can help in selecting and using control valves effectively.

For example, the inherent rangeability of a valve represents the highest and lowest Cv values at which the valve can effectively control flow without deviating from a desired flow characteristic. The valve’s design plays a significant role here, with different valve types having unique inherent rangeability characteristics. Manufacturers typically provide inherent rangeability values based on standardized testing, which can guide users in selecting valves that meet general flow control needs. Installed rangeability, on the other hand, describes a valve’s range under actual operating conditions within a specific system. Unlike inherent rangeability, installed rangeability considers the influence of system variables—such as pressure fluctuations and flow demands—that can impact a valve’s performance.

In this case, rangeability is defined as the ratio between the maximum and minimum flow rates that the valve can control within a specified tolerance. Installed rangeability accounts for how the valve responds to real-world conditions, which may affect its ability to maintain a consistent gain (or sensitivity) in controlling flow. Generally, the installed gain should remain stable within a defined limit, as significant deviations can compromise controllability.

For practical purposes, a rule of thumb for installed gain limits is that a gain change of more than 4 should be avoided, as this can reduce the system’s responsiveness. In critical applications with stringent control requirements, even tighter gain tolerances, such as 2 or 3, are often preferred. A variety of factors influence rangeability, especially when considering installed rangeability in dynamic environments. Key factors include: The valve type—whether it’s a globe valve, butterfly valve, or ball valve—significantly affects rangeability. High-performance butterfly valves, for example, often demonstrate good controllability and minimal friction, allowing them to maintain stable flow control even when the installed gain fluctuates. Such valves are well-suited to applications with broad rangeability needs, especially where frictionless movement is advantageous. A valve’s responsiveness to control signals plays a role in defining its effective range. A valve with high sensitivity to small signal changes allows for finer adjustments across its range, enhancing its controllability and extending its practical rangeability. Advanced control methods, such as gain scheduling and characterization, can improve a valve’s installed rangeability by adjusting gain in response to system conditions. These techniques can compensate for variability, helping maintain a steady response even as system demands shift. However, they can also complicate the precise definition of rangeability, as they introduce variability that may differ between systems or vendors. Since rangeability is not strictly defined across the industry, valve manufacturers may apply different standards or testing methods, which can lead to inconsistencies. Some manufacturers may provide inherent rangeability data that overestimates the valve’s effective control range in real-world scenarios, so it’s essential to examine both inherent and installed rangeability when evaluating valve specifications. Rangeability is a key factor when choosing a control valve, as it directly impacts how well the valve can accommodate varying flow rates within the same system. Valves with high rangeability are desirable in systems where flow demand fluctuates widely, as they provide reliable performance across a broad spectrum of conditions. For instance, in a manufacturing process with rapidly changing flow rates, a valve with low rangeability may struggle to maintain control, leading to inefficiencies or even equipment damage.

In contrast, a high-rangeability valve can handle these changes with greater ease, reducing the likelihood of control issues and increasing overall system efficiency. When choosing valves, engineers should carefully assess rangeability requirements based on the operational needs and the criticality of maintaining consistent control. Due to the ambiguity surrounding rangeability definitions, efforts are underway to create standardized guidelines. Organizations like the International Electrotechnical Commission (IEC) are exploring ways to harmonize rangeability definitions across manufacturers, which would help reduce confusion and allow for clearer comparisons when selecting valves.

Standardized definitions of inherent and installed rangeability would benefit both manufacturers and end-users by providing a common basis for evaluating valve performance. Clearer standards would simplify the valve selection process, especially for complex control systems where precise flow control is essential. Rangeability is a crucial yet often misunderstood aspect of control valve performance. With two primary definitions—inherent and installed rangeability—this measure represents a valve’s capacity to maintain accurate control across a range of flow rates. While inherent rangeability provides a baseline measurement under ideal conditions, installed rangeability accounts for real-world variables that affect a valve’s performance within a system.

Several factors, including valve type, signal sensitivity, and control techniques, influence a valve's effective rangeability, making it important to consider both types when evaluating valve options. Although industry standards for rangeability remain inconsistent, efforts by international standardization organizations aim to create a more unified approach in the future. Until then, understanding the nuances of rangeability will enable engineers to select control valves that best meet their specific application needs.

1. Inherent Rangeability

2. Installed Rangeability

For example, the inherent rangeability of a valve represents the highest and lowest Cv values at which the valve can effectively control flow without deviating from a desired flow characteristic. The valve’s design plays a significant role here, with different valve types having unique inherent rangeability characteristics. Manufacturers typically provide inherent rangeability values based on standardized testing, which can guide users in selecting valves that meet general flow control needs. Installed rangeability, on the other hand, describes a valve’s range under actual operating conditions within a specific system. Unlike inherent rangeability, installed rangeability considers the influence of system variables—such as pressure fluctuations and flow demands—that can impact a valve’s performance.

In this case, rangeability is defined as the ratio between the maximum and minimum flow rates that the valve can control within a specified tolerance. Installed rangeability accounts for how the valve responds to real-world conditions, which may affect its ability to maintain a consistent gain (or sensitivity) in controlling flow. Generally, the installed gain should remain stable within a defined limit, as significant deviations can compromise controllability.

For practical purposes, a rule of thumb for installed gain limits is that a gain change of more than 4 should be avoided, as this can reduce the system’s responsiveness. In critical applications with stringent control requirements, even tighter gain tolerances, such as 2 or 3, are often preferred. A variety of factors influence rangeability, especially when considering installed rangeability in dynamic environments. Key factors include: The valve type—whether it’s a globe valve, butterfly valve, or ball valve—significantly affects rangeability. High-performance butterfly valves, for example, often demonstrate good controllability and minimal friction, allowing them to maintain stable flow control even when the installed gain fluctuates. Such valves are well-suited to applications with broad rangeability needs, especially where frictionless movement is advantageous. A valve’s responsiveness to control signals plays a role in defining its effective range. A valve with high sensitivity to small signal changes allows for finer adjustments across its range, enhancing its controllability and extending its practical rangeability. Advanced control methods, such as gain scheduling and characterization, can improve a valve’s installed rangeability by adjusting gain in response to system conditions. These techniques can compensate for variability, helping maintain a steady response even as system demands shift. However, they can also complicate the precise definition of rangeability, as they introduce variability that may differ between systems or vendors. Since rangeability is not strictly defined across the industry, valve manufacturers may apply different standards or testing methods, which can lead to inconsistencies. Some manufacturers may provide inherent rangeability data that overestimates the valve’s effective control range in real-world scenarios, so it’s essential to examine both inherent and installed rangeability when evaluating valve specifications. Rangeability is a key factor when choosing a control valve, as it directly impacts how well the valve can accommodate varying flow rates within the same system. Valves with high rangeability are desirable in systems where flow demand fluctuates widely, as they provide reliable performance across a broad spectrum of conditions. For instance, in a manufacturing process with rapidly changing flow rates, a valve with low rangeability may struggle to maintain control, leading to inefficiencies or even equipment damage.

In contrast, a high-rangeability valve can handle these changes with greater ease, reducing the likelihood of control issues and increasing overall system efficiency. When choosing valves, engineers should carefully assess rangeability requirements based on the operational needs and the criticality of maintaining consistent control. Due to the ambiguity surrounding rangeability definitions, efforts are underway to create standardized guidelines. Organizations like the International Electrotechnical Commission (IEC) are exploring ways to harmonize rangeability definitions across manufacturers, which would help reduce confusion and allow for clearer comparisons when selecting valves.

Standardized definitions of inherent and installed rangeability would benefit both manufacturers and end-users by providing a common basis for evaluating valve performance. Clearer standards would simplify the valve selection process, especially for complex control systems where precise flow control is essential. Rangeability is a crucial yet often misunderstood aspect of control valve performance. With two primary definitions—inherent and installed rangeability—this measure represents a valve’s capacity to maintain accurate control across a range of flow rates. While inherent rangeability provides a baseline measurement under ideal conditions, installed rangeability accounts for real-world variables that affect a valve’s performance within a system.

Several factors, including valve type, signal sensitivity, and control techniques, influence a valve's effective rangeability, making it important to consider both types when evaluating valve options. Although industry standards for rangeability remain inconsistent, efforts by international standardization organizations aim to create a more unified approach in the future. Until then, understanding the nuances of rangeability will enable engineers to select control valves that best meet their specific application needs.