What is a Wafer Style Control Valve & How Do They Work?

On this page

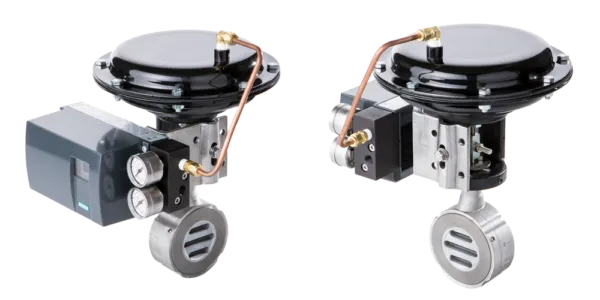

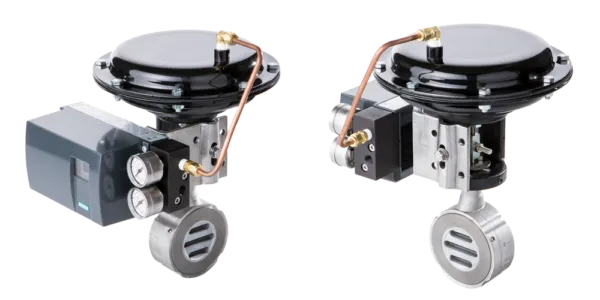

Wafer style control valves have emerged as a favored solution in various industrial applications, known for their efficiency and effectiveness in controlling fluid flow. These valves, characterized by their compact design and straightforward installation, offer numerous advantages that make them an attractive choice for engineers and operators alike. This article will delve into the features, benefits, and operational mechanisms of wafer style control valves, focusing on their sliding gate design.

Wafer style control valves are uniquely designed to be mounted between flanges in piping systems, eliminating the need for bulky end connections. Their flat, compact body allows for installation in tight spaces where traditional valves might not fit. The sliding gate design enables precise flow control, making these valves ideal for a variety of applications, from water treatment to oil and gas processing.

One of the primary benefits of wafer style control valves is their ability to minimize air consumption. This efficiency translates to lower operational costs, making them a cost-effective solution for various industrial processes. Their design allows for optimal flow control while using less energy, leading to significant savings over time.

The wafer body design simplifies the installation process. These valves can be easily sandwiched between flanges, which reduces installation time and labor costs. This straightforward installation method is especially beneficial in facilities with limited space or where downtime needs to be minimized.

Wafer style control valves offer interchangeable flow coefficients (Cv), allowing for greater flexibility in system design. Operators can easily adjust the Cv to meet specific flow requirements, making these valves versatile for different applications. This adaptability enhances their usability across various systems without the need for additional equipment or modifications.

The sliding gate design of these valves ensures precise control over fluid flow. By adjusting the position of the gate, operators can achieve the desired flow rate, pressure, and velocity. This feature is crucial in applications where exact flow measurements are necessary for optimal performance.

Maintenance is a critical aspect of valve management, and wafer style control valves excel in this area. Their design incorporates a ‘T’ slot connection into the disc, allowing for quick and easy reversal of functions. This feature enables operators to perform routine maintenance with minimal disruption to the system, ensuring continued reliability and performance.

The wafer style body design of these valves offers a significant pricing advantage in the marketplace. Their compact structure not only reduces manufacturing costs but also translates into lower prices for end-users. This competitive pricing makes wafer style control valves an appealing option for businesses looking to optimize their budgets without compromising on quality.

Wafer style control valves are typically lighter than traditional valves, which offers both economic and practical benefits. The reduced weight means lower shipping costs and less physical strain during installation. Additionally, the lightweight nature allows for easier handling and support, especially in larger installations where multiple valves are used.

Despite their smaller size, wafer style control valves boast impressive capacity. Their efficient design maximizes flow while maintaining a compact footprint, making them suitable for applications with space constraints. This combination of capacity and compactness allows engineers to design systems that utilize available space effectively without sacrificing performance.

Maintenance is a crucial factor in the longevity and efficiency of control valves. The ‘T’ slot design of wafer style control valves simplifies maintenance tasks. Operators can quickly reverse functions or replace components without the need for extensive disassembly. This ease of access saves valuable time and resources, contributing to the overall efficiency of the operation.

The operational principle of wafer style control valves is relatively straightforward. The valve consists of a disc that slides within the valve body to regulate fluid flow. When the valve is closed, the disc blocks the flow path, preventing any fluid from passing through. As the valve is opened, the disc slides away from the flow path, allowing fluid to pass through.

The sliding gate mechanism is the heart of the wafer style control valve's functionality. This design allows for smooth and precise adjustments to the flow rate. Operators can control the position of the disc via an actuator, which can be manual or automated, depending on the application.

Wafer style control valves are widely used across various industries due to their versatility and reliability. Common applications include:

Used to control the flow of water through treatment systems, ensuring optimal filtration and chemical dosing.

Wafer style control valves are uniquely designed to be mounted between flanges in piping systems, eliminating the need for bulky end connections. Their flat, compact body allows for installation in tight spaces where traditional valves might not fit. The sliding gate design enables precise flow control, making these valves ideal for a variety of applications, from water treatment to oil and gas processing.

One of the primary benefits of wafer style control valves is their ability to minimize air consumption. This efficiency translates to lower operational costs, making them a cost-effective solution for various industrial processes. Their design allows for optimal flow control while using less energy, leading to significant savings over time.

The wafer body design simplifies the installation process. These valves can be easily sandwiched between flanges, which reduces installation time and labor costs. This straightforward installation method is especially beneficial in facilities with limited space or where downtime needs to be minimized.

Wafer style control valves offer interchangeable flow coefficients (Cv), allowing for greater flexibility in system design. Operators can easily adjust the Cv to meet specific flow requirements, making these valves versatile for different applications. This adaptability enhances their usability across various systems without the need for additional equipment or modifications.

The sliding gate design of these valves ensures precise control over fluid flow. By adjusting the position of the gate, operators can achieve the desired flow rate, pressure, and velocity. This feature is crucial in applications where exact flow measurements are necessary for optimal performance.

Maintenance is a critical aspect of valve management, and wafer style control valves excel in this area. Their design incorporates a ‘T’ slot connection into the disc, allowing for quick and easy reversal of functions. This feature enables operators to perform routine maintenance with minimal disruption to the system, ensuring continued reliability and performance.

The wafer style body design of these valves offers a significant pricing advantage in the marketplace. Their compact structure not only reduces manufacturing costs but also translates into lower prices for end-users. This competitive pricing makes wafer style control valves an appealing option for businesses looking to optimize their budgets without compromising on quality.

Wafer style control valves are typically lighter than traditional valves, which offers both economic and practical benefits. The reduced weight means lower shipping costs and less physical strain during installation. Additionally, the lightweight nature allows for easier handling and support, especially in larger installations where multiple valves are used.

Despite their smaller size, wafer style control valves boast impressive capacity. Their efficient design maximizes flow while maintaining a compact footprint, making them suitable for applications with space constraints. This combination of capacity and compactness allows engineers to design systems that utilize available space effectively without sacrificing performance.

Maintenance is a crucial factor in the longevity and efficiency of control valves. The ‘T’ slot design of wafer style control valves simplifies maintenance tasks. Operators can quickly reverse functions or replace components without the need for extensive disassembly. This ease of access saves valuable time and resources, contributing to the overall efficiency of the operation.

The operational principle of wafer style control valves is relatively straightforward. The valve consists of a disc that slides within the valve body to regulate fluid flow. When the valve is closed, the disc blocks the flow path, preventing any fluid from passing through. As the valve is opened, the disc slides away from the flow path, allowing fluid to pass through.

The sliding gate mechanism is the heart of the wafer style control valve's functionality. This design allows for smooth and precise adjustments to the flow rate. Operators can control the position of the disc via an actuator, which can be manual or automated, depending on the application.

Wafer style control valves are widely used across various industries due to their versatility and reliability. Common applications include:

Used to control the flow of water through treatment systems, ensuring optimal filtration and chemical dosing.

Oil and Gas: Essential for regulating the flow of hydrocarbons in pipelines and processing plants. Employed in heating, ventilation, and air conditioning systems to maintain desired temperatures and airflow. Utilized to control fluid flow in processing and packaging applications, ensuring safety and compliance with industry standards. Wafer style control valves are an excellent choice for industries seeking efficient and reliable flow control solutions. With advantages such as reduced air consumption, easy installation, interchangeable Cv's, and low maintenance requirements, these valves offer significant benefits over traditional valve designs. Their compact, lightweight construction provides additional cost savings and flexibility in various applications. As industries continue to prioritize efficiency and performance, wafer style control valves are poised to play a critical role in enhancing operational effectiveness across the board.

Wafer style control valves are uniquely designed to be mounted between flanges in piping systems, eliminating the need for bulky end connections. Their flat, compact body allows for installation in tight spaces where traditional valves might not fit. The sliding gate design enables precise flow control, making these valves ideal for a variety of applications, from water treatment to oil and gas processing.

One of the primary benefits of wafer style control valves is their ability to minimize air consumption. This efficiency translates to lower operational costs, making them a cost-effective solution for various industrial processes. Their design allows for optimal flow control while using less energy, leading to significant savings over time.

The wafer body design simplifies the installation process. These valves can be easily sandwiched between flanges, which reduces installation time and labor costs. This straightforward installation method is especially beneficial in facilities with limited space or where downtime needs to be minimized.

Wafer style control valves offer interchangeable flow coefficients (Cv), allowing for greater flexibility in system design. Operators can easily adjust the Cv to meet specific flow requirements, making these valves versatile for different applications. This adaptability enhances their usability across various systems without the need for additional equipment or modifications.

The sliding gate design of these valves ensures precise control over fluid flow. By adjusting the position of the gate, operators can achieve the desired flow rate, pressure, and velocity. This feature is crucial in applications where exact flow measurements are necessary for optimal performance.

Maintenance is a critical aspect of valve management, and wafer style control valves excel in this area. Their design incorporates a ‘T’ slot connection into the disc, allowing for quick and easy reversal of functions. This feature enables operators to perform routine maintenance with minimal disruption to the system, ensuring continued reliability and performance.

The wafer style body design of these valves offers a significant pricing advantage in the marketplace. Their compact structure not only reduces manufacturing costs but also translates into lower prices for end-users. This competitive pricing makes wafer style control valves an appealing option for businesses looking to optimize their budgets without compromising on quality.

Wafer style control valves are typically lighter than traditional valves, which offers both economic and practical benefits. The reduced weight means lower shipping costs and less physical strain during installation. Additionally, the lightweight nature allows for easier handling and support, especially in larger installations where multiple valves are used.

Despite their smaller size, wafer style control valves boast impressive capacity. Their efficient design maximizes flow while maintaining a compact footprint, making them suitable for applications with space constraints. This combination of capacity and compactness allows engineers to design systems that utilize available space effectively without sacrificing performance.

Maintenance is a crucial factor in the longevity and efficiency of control valves. The ‘T’ slot design of wafer style control valves simplifies maintenance tasks. Operators can quickly reverse functions or replace components without the need for extensive disassembly. This ease of access saves valuable time and resources, contributing to the overall efficiency of the operation.

The operational principle of wafer style control valves is relatively straightforward. The valve consists of a disc that slides within the valve body to regulate fluid flow. When the valve is closed, the disc blocks the flow path, preventing any fluid from passing through. As the valve is opened, the disc slides away from the flow path, allowing fluid to pass through.

The sliding gate mechanism is the heart of the wafer style control valve's functionality. This design allows for smooth and precise adjustments to the flow rate. Operators can control the position of the disc via an actuator, which can be manual or automated, depending on the application.

Wafer style control valves are widely used across various industries due to their versatility and reliability. Common applications include:

Used to control the flow of water through treatment systems, ensuring optimal filtration and chemical dosing.

Wafer style control valves are uniquely designed to be mounted between flanges in piping systems, eliminating the need for bulky end connections. Their flat, compact body allows for installation in tight spaces where traditional valves might not fit. The sliding gate design enables precise flow control, making these valves ideal for a variety of applications, from water treatment to oil and gas processing.

One of the primary benefits of wafer style control valves is their ability to minimize air consumption. This efficiency translates to lower operational costs, making them a cost-effective solution for various industrial processes. Their design allows for optimal flow control while using less energy, leading to significant savings over time.

The wafer body design simplifies the installation process. These valves can be easily sandwiched between flanges, which reduces installation time and labor costs. This straightforward installation method is especially beneficial in facilities with limited space or where downtime needs to be minimized.

Wafer style control valves offer interchangeable flow coefficients (Cv), allowing for greater flexibility in system design. Operators can easily adjust the Cv to meet specific flow requirements, making these valves versatile for different applications. This adaptability enhances their usability across various systems without the need for additional equipment or modifications.

The sliding gate design of these valves ensures precise control over fluid flow. By adjusting the position of the gate, operators can achieve the desired flow rate, pressure, and velocity. This feature is crucial in applications where exact flow measurements are necessary for optimal performance.

Maintenance is a critical aspect of valve management, and wafer style control valves excel in this area. Their design incorporates a ‘T’ slot connection into the disc, allowing for quick and easy reversal of functions. This feature enables operators to perform routine maintenance with minimal disruption to the system, ensuring continued reliability and performance.

The wafer style body design of these valves offers a significant pricing advantage in the marketplace. Their compact structure not only reduces manufacturing costs but also translates into lower prices for end-users. This competitive pricing makes wafer style control valves an appealing option for businesses looking to optimize their budgets without compromising on quality.

Wafer style control valves are typically lighter than traditional valves, which offers both economic and practical benefits. The reduced weight means lower shipping costs and less physical strain during installation. Additionally, the lightweight nature allows for easier handling and support, especially in larger installations where multiple valves are used.

Despite their smaller size, wafer style control valves boast impressive capacity. Their efficient design maximizes flow while maintaining a compact footprint, making them suitable for applications with space constraints. This combination of capacity and compactness allows engineers to design systems that utilize available space effectively without sacrificing performance.

Maintenance is a crucial factor in the longevity and efficiency of control valves. The ‘T’ slot design of wafer style control valves simplifies maintenance tasks. Operators can quickly reverse functions or replace components without the need for extensive disassembly. This ease of access saves valuable time and resources, contributing to the overall efficiency of the operation.

The operational principle of wafer style control valves is relatively straightforward. The valve consists of a disc that slides within the valve body to regulate fluid flow. When the valve is closed, the disc blocks the flow path, preventing any fluid from passing through. As the valve is opened, the disc slides away from the flow path, allowing fluid to pass through.

The sliding gate mechanism is the heart of the wafer style control valve's functionality. This design allows for smooth and precise adjustments to the flow rate. Operators can control the position of the disc via an actuator, which can be manual or automated, depending on the application.

Wafer style control valves are widely used across various industries due to their versatility and reliability. Common applications include:

Used to control the flow of water through treatment systems, ensuring optimal filtration and chemical dosing.Oil and Gas: Essential for regulating the flow of hydrocarbons in pipelines and processing plants. Employed in heating, ventilation, and air conditioning systems to maintain desired temperatures and airflow. Utilized to control fluid flow in processing and packaging applications, ensuring safety and compliance with industry standards. Wafer style control valves are an excellent choice for industries seeking efficient and reliable flow control solutions. With advantages such as reduced air consumption, easy installation, interchangeable Cv's, and low maintenance requirements, these valves offer significant benefits over traditional valve designs. Their compact, lightweight construction provides additional cost savings and flexibility in various applications. As industries continue to prioritize efficiency and performance, wafer style control valves are poised to play a critical role in enhancing operational effectiveness across the board.