In modern industrial fluid control systems, valves play a crucial role in regulating flow, ensuring safety, and maintaining operational efficiency. Among the wide variety of valve types available today, pneumatic PTFE lined butterfly valves have gained significant attention for their ability to handle corrosive media, provide reliable sealing, and deliver automated performance. These valves combine the advantages of butterfly valve design, pneumatic actuation, and polytetrafluoroethylene (PTFE) lining technology to create a solution suited for demanding chemical, pharmaceutical, water treatment, and process industries.

As industries increasingly require corrosion resistance, automation compatibility, and long service life, pneumatic PTFE lined butterfly valves have become a preferred choice for engineers and plant operators seeking dependable and cost-effective flow control solutions. This article explores their design principles, components, working mechanism, benefits, applications, selection criteria, maintenance requirements, and future industry outlook.

Butterfly valves are quarter-turn rotary valves designed to regulate or isolate fluid flow. They consist of a circular disc mounted on a rotating shaft. When the disc is turned parallel to the flow, fluid passes freely; when rotated perpendicular, flow is restricted or stopped. Their simple structure, lightweight design, and fast operation make butterfly valves widely used in industrial pipelines.

Compared to gate or globe valves, butterfly valves require less space, operate more quickly, and offer lower installation costs. They are particularly suitable for large-diameter pipelines and applications where rapid shut-off or modulation is necessary. However, standard butterfly valves may not always withstand highly corrosive or chemically aggressive fluids. This limitation led to the development of lined butterfly valves, which incorporate protective materials such as PTFE to improve chemical resistance.

A pneumatic PTFE lined butterfly valve is an automated valve that uses compressed air to actuate the valve and PTFE lining to protect internal components from corrosion. It integrates three primary technologies:

- Butterfly Valve Structure – Provides compact, efficient flow control.

- Pneumatic Actuator – Enables automatic operation through air pressure.

- PTFE Lining – Offers chemical resistance and superior sealing performance.

This combination makes the valve suitable for aggressive chemical environments where manual operation would be impractical or hazardous. Pneumatic actuation also allows integration with control systems, enabling remote operation, automation, and precise flow regulation.

Understanding the construction of pneumatic PTFE lined butterfly valves helps illustrate why they perform well in demanding environments.

The body is typically made from ductile iron, carbon steel, or stainless steel, depending on application requirements. The interior is fully lined with PTFE, forming a protective barrier between the process fluid and the metal body.

PTFE is a fluoropolymer known for its exceptional chemical resistance, low friction coefficient, and high temperature tolerance. The lining prevents corrosive fluids from contacting metal surfaces, significantly extending valve service life.

The disc controls flow and is often coated or encapsulated with PTFE or other corrosion-resistant materials. In high-performance designs, the disc may be precision-machined to improve sealing and reduce torque requirements.

The shaft connects the actuator to the disc and transmits rotational motion. It is typically constructed from stainless steel or other corrosion-resistant alloys.

The seat provides sealing when the valve is closed. In lined butterfly valves, the seat is often integrated with the PTFE liner, creating a leak-tight seal and reducing the number of separate components.

The actuator converts compressed air into mechanical motion. Common types include double-acting and spring-return actuators. Double-acting actuators use air pressure for both opening and closing, while spring-return actuators use air pressure in one direction and a spring for fail-safe operation.

Advanced valves may include positioners, limit switches, solenoid valves, and air filters to enhance automation and control accuracy.

The operating principle of a pneumatic PTFE lined butterfly valve is straightforward yet efficient. Compressed air is supplied to the actuator through a control signal. The actuator then rotates the valve stem, which turns the disc inside the valve body. As the disc rotates, it either allows fluid to pass or blocks the flow.

When the disc is parallel to the pipeline, flow resistance is minimal. When rotated perpendicular, the disc seals against the seat, stopping flow completely. Because the valve requires only a quarter-turn rotation, it operates quickly and efficiently, making it suitable for automated processes where speed and reliability are critical.

These valves offer numerous advantages that make them attractive across industries:

The PTFE lining protects internal metal surfaces from aggressive chemicals, acids, alkalis, and solvents. This makes the valve ideal for corrosive service environments.

The integrated lining and seat design provides excellent sealing performance, minimizing leakage and ensuring safe operation.

Pneumatic actuation allows remote control, integration with control systems, and automated process regulation, reducing manual labor and improving operational safety.

Quarter-turn design enables rapid opening and closing, making the valve suitable for emergency shut-off applications.

Compared to other valve types, butterfly valves are lighter and require less installation space, reducing structural support requirements.

The simple design and corrosion-resistant lining reduce wear and extend maintenance intervals.

These valves often provide a lower total cost of ownership compared to more complex valve types, especially in corrosive environments.

Pneumatic PTFE lined butterfly valves are widely used in industries where corrosive media, automation, and reliability are key requirements.

Chemical plants handle aggressive substances such as acids, alkalis, and solvents. PTFE lining ensures compatibility with these fluids while preventing corrosion.

Cleanliness and contamination prevention are critical in pharmaceutical production. PTFE’s non-reactive properties help maintain product purity.

In wastewater treatment and desalination plants, valves must withstand chemicals used for purification and disinfection. Lined butterfly valves provide reliable performance in these conditions.

PTFE is non-toxic and chemically inert, making it suitable for certain hygienic applications when designed according to sanitary standards.

Pulp processing involves abrasive and corrosive chemicals. Lined valves resist degradation and maintain performance.

Slurries and chemical reagents used in mineral processing require valves that resist corrosion and wear.

When selecting valves for corrosive or automated systems, engineers often compare pneumatic PTFE lined butterfly valves with alternatives such as ball valves, gate valves, and globe valves.

Compared to ball valves, butterfly valves are lighter and more economical for large diameters. Ball valves may provide tighter shut-off in certain applications, but lined butterfly valves often offer sufficient sealing with lower weight and cost.

Compared to gate valves, butterfly valves operate faster and require less space. Gate valves are typically better for full open or full close service, whereas butterfly valves can also be used for throttling.

Compared to globe valves, butterfly valves provide lower pressure drop and faster actuation, though globe valves may offer finer flow control in precise regulation systems.

Choosing the right pneumatic PTFE lined butterfly valve requires careful evaluation of operating conditions and system requirements.

Chemical composition, temperature, pressure, and viscosity must be compatible with PTFE lining and valve materials.

Ensure the valve is rated for the system’s maximum operating conditions.

Select between double-acting and spring-return actuators depending on fail-safe requirements.

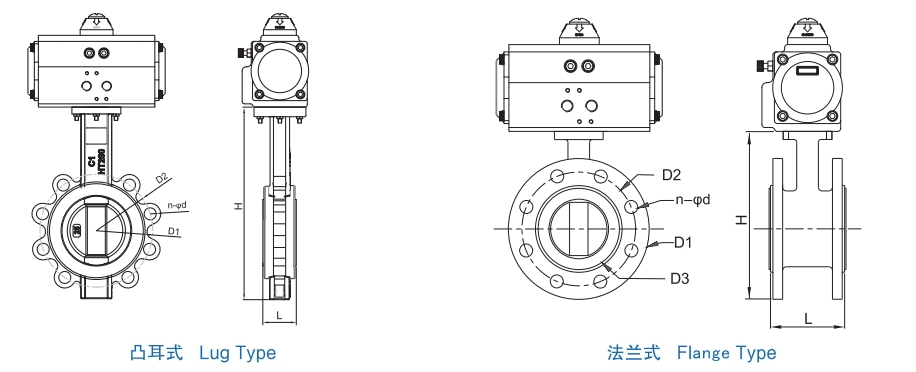

Flanged, wafer, or lug-style connections must match pipeline specifications.

If precise modulation is needed, a positioner may be required for accurate valve positioning.

Compliance with international standards such as API, ISO, or DIN ensures reliability and safety.

Proper installation is essential for optimal performance and longevity. The valve should be installed in a clean pipeline free of debris to prevent damage to the PTFE lining. Alignment must be accurate to avoid stress on the valve body. Adequate support should be provided for large-diameter valves to prevent pipeline strain.

Air supply lines must be clean, dry, and filtered to ensure smooth actuator operation. Incorrect air pressure or contaminated air can lead to actuator malfunction or reduced lifespan.

Although pneumatic PTFE lined butterfly valves require minimal maintenance, periodic inspection is recommended to ensure reliable operation. Maintenance practices typically include:

- Checking actuator performance and air supply pressure

- Inspecting seals and gaskets for wear

- Verifying proper disc movement

- Cleaning external surfaces to prevent contamination

If leakage occurs, the seat or lining may need replacement. Slow operation may indicate insufficient air pressure or actuator wear. Preventive maintenance programs can significantly extend valve life and reduce unexpected downtime.

Safety is a critical factor in industrial valve operation. Pneumatic PTFE lined butterfly valves offer several safety advantages, including remote operation, which keeps personnel away from hazardous environments. Spring-return actuators can be configured for fail-open or fail-closed operation in emergencies.

Proper training for operators and maintenance staff is essential. Valves should always be installed and serviced according to manufacturer guidelines to prevent accidents and equipment damage.

Recent technological developments have further improved the performance of pneumatic PTFE lined butterfly valves. Innovations include:

- Enhanced PTFE formulations for higher temperature resistance

- Precision-machined discs for improved sealing

- Smart positioners with digital control interfaces

- Lightweight actuator materials for faster response

- Anti-static designs for hazardous environments

Digital monitoring systems now allow real-time valve performance tracking, predictive maintenance, and integration with industrial automation platforms. These advancements are driving adoption in smart manufacturing and Industry 4.0 environments.

From an environmental standpoint, corrosion-resistant valves reduce the risk of leaks and chemical spills, protecting workers and ecosystems. Their long lifespan also reduces material waste and replacement frequency.

Economically, automated valves improve process efficiency, reduce manual labor, and minimize downtime. Although initial investment may be higher than manual valves, the long-term savings often justify the cost.

Global demand for pneumatic PTFE lined butterfly valves continues to grow as industries modernize infrastructure and prioritize automation. The expansion of chemical manufacturing, water treatment facilities, and renewable energy projects has increased the need for corrosion-resistant flow control solutions.

Manufacturers are focusing on producing valves with higher performance standards, improved durability, and compliance with international regulations. Customization is also becoming more common, allowing clients to specify materials, actuator types, and control features tailored to their processes.

Emerging markets in Asia, the Middle East, and South America are expected to drive future growth, supported by industrial expansion and infrastructure investment. Meanwhile, developed regions are upgrading existing facilities with advanced automated valves to improve efficiency and safety.

Pneumatic PTFE lined butterfly valves represent a sophisticated solution for modern industrial flow control. By combining the simplicity of butterfly valve design, the automation capability of pneumatic actuators, and the corrosion resistance of PTFE lining, these valves deliver reliable performance in challenging environments.

Their advantages—such as quick operation, chemical resistance, low maintenance, and cost efficiency—make them suitable for a wide range of industries, including chemical processing, water treatment, pharmaceuticals, and mining. With ongoing technological advancements and growing global demand for automated and corrosion-resistant equipment, pneumatic PTFE lined butterfly valves are poised to remain a vital component of industrial systems for years to come.

For engineers, plant managers, and procurement specialists, understanding the design, benefits, and selection criteria of these valves is essential to ensuring safe, efficient, and long-lasting fluid control operations.