Advantages and Applications of Electric Ball Control Valves

On this page

Electric ball Control valves have emerged as a critical component in modern industrial systems due to their numerous advantages and wide range of applications. These valves are highly efficient, reliable, and versatile, making them suitable for various industries. This article delves into the key advantages and applications of Electric ball Control valves, highlighting why they are favored in many industrial settings.

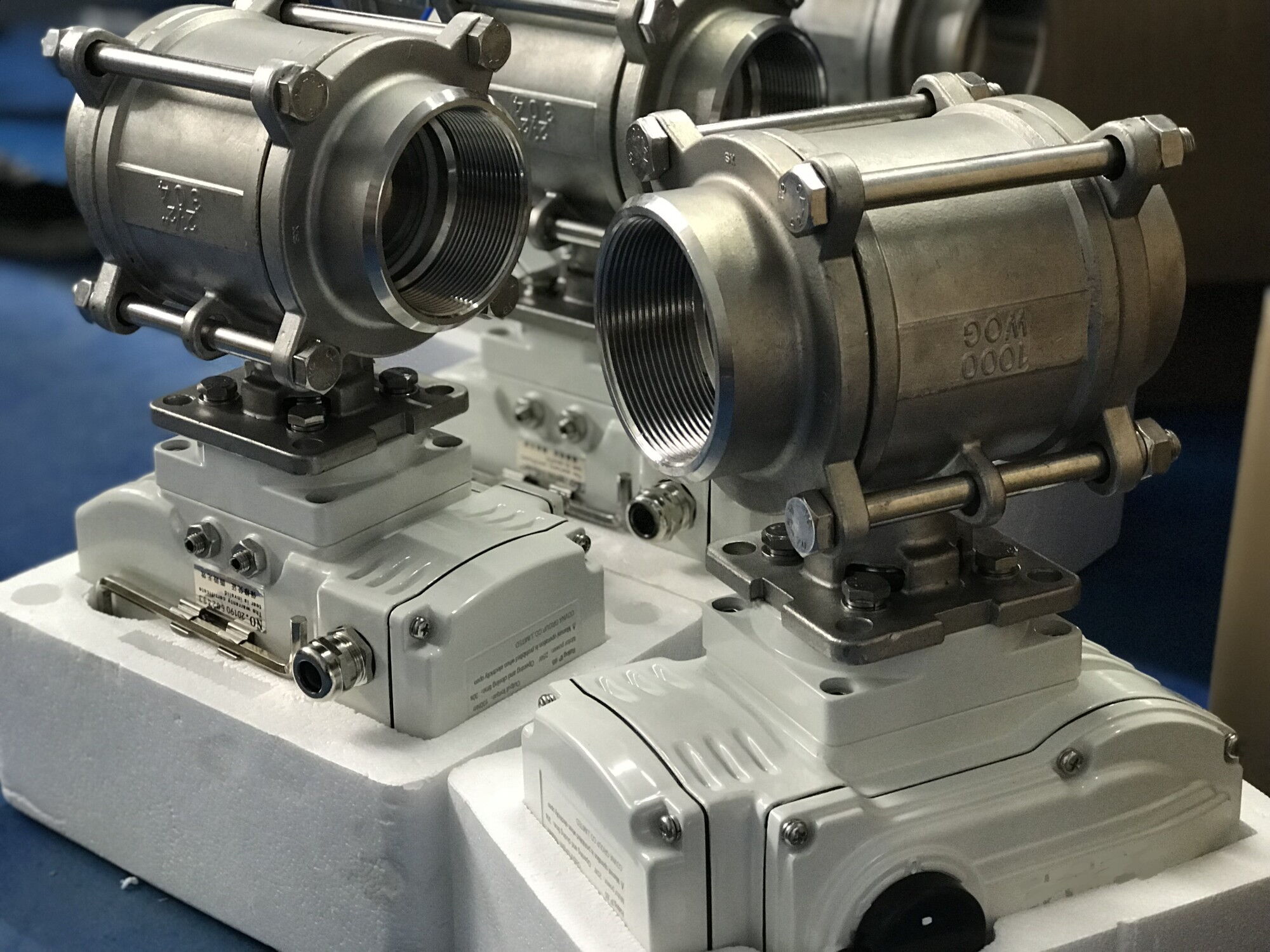

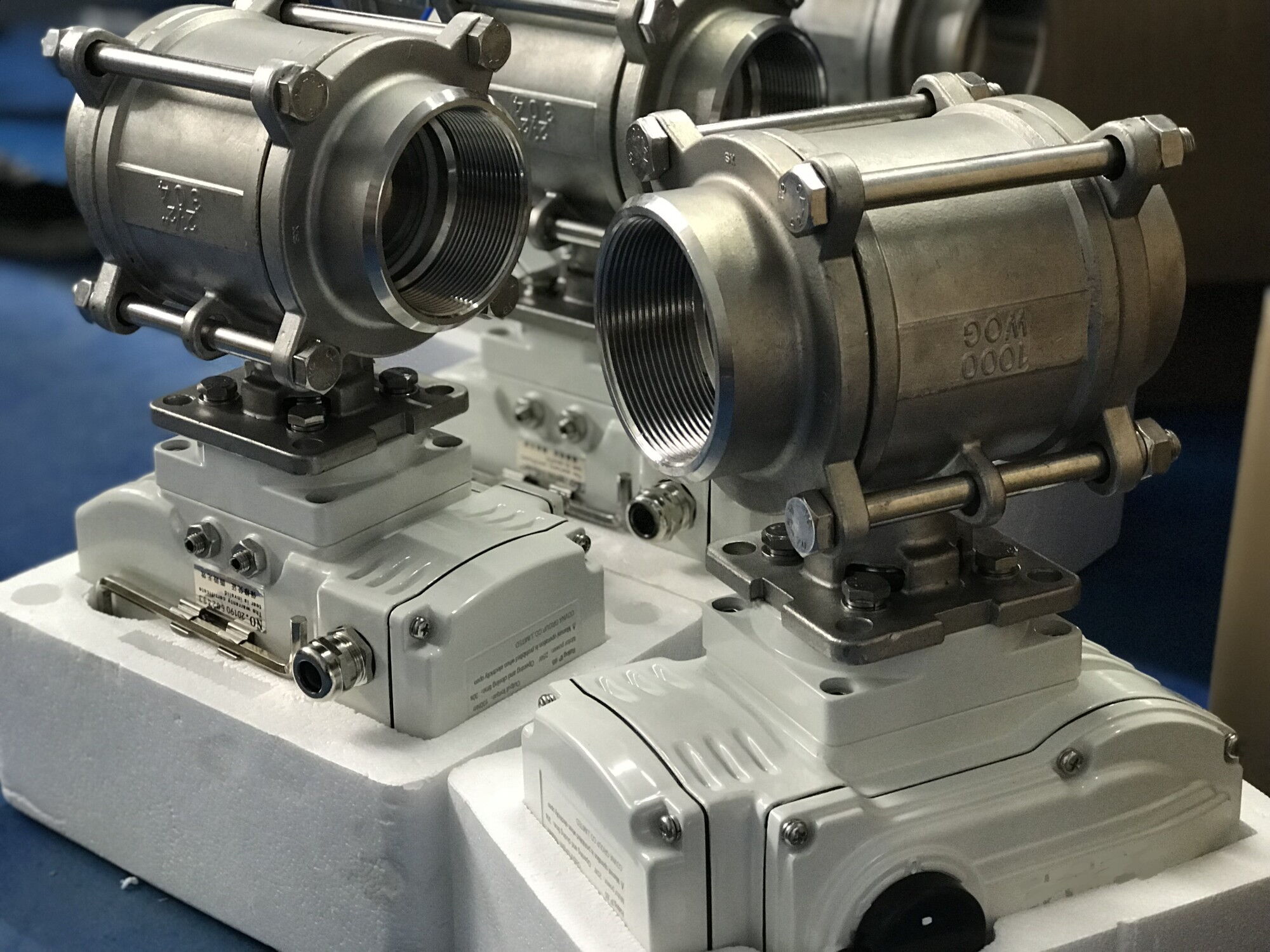

Electric Ball Control Valves

Electric ball Control valves offer precise control over the flow of liquids and gases. The electric actuator can accurately position the ball within the valve, allowing for fine adjustments to the flow rate. This precision is crucial in processes where exact flow control is necessary, such as in chemical dosing or water treatment.

One of the most significant advantages of Electric ball Control valves is their ability to be automated and operated remotely. This feature allows for integration into automated systems, enabling centralized control and monitoring. In large industrial plants, this capability reduces the need for manual intervention, enhancing operational efficiency and safety.

Electric ball Control valves are known for their robust construction and long service life. The materials used in these valves, such as stainless steel, brass, and high-grade plastics, are resistant to corrosion and wear. This durability ensures reliable performance over extended periods, even in harsh environments.

Compared to other types of valves, Electric ball Control valves are energy-efficient. The electric actuators consume power only when changing positions, unlike pneumatic or hydraulic systems that may require a continuous energy supply. This efficiency can lead to significant energy savings in industrial operations.

Electric ball Control valves provide quick and reliable operation, with fast opening and closing times. This responsiveness is essential in applications where quick shutoff or precise flow adjustments are required to maintain process stability and safety.

The design of Electric ball Control valves minimizes the need for regular maintenance. The sealed nature of the valve body and the absence of sliding parts reduce wear and tear, resulting in lower maintenance costs and less downtime.

In water and wastewater treatment plants, Electric ball Control valves are used to control the flow of water, chemicals, and sludge. Their precise control capabilities ensure the accurate dosing of treatment chemicals and the efficient management of water flow through various treatment stages.

The oil and gas industry relies on Electric ball Control valves for controlling the flow of crude oil, natural gas, and refined products. These valves are used in pipelines, storage facilities, and processing plants, where their reliability and durability are critical for safe and efficient operations.

Electric ball Control valves are widely used in chemical processing industries to handle a variety of chemicals, including corrosive and hazardous substances. The precise control offered by these valves ensures safe and efficient chemical reactions and mixing processes.

Heating, ventilation, and air conditioning (HVAC) systems use Electric ball Control valves to regulate the flow of heating and cooling fluids. These valves help maintain optimal temperatures and improve the energy efficiency of HVAC systems in commercial and industrial buildings.

In the food and beverage industry, Electric ball Control valves are essential for controlling the flow of ingredients, water, and cleaning agents. Their hygienic design and reliable operation are crucial for maintaining product quality and safety.

Pharmaceutical manufacturing processes require precise control over the flow of various liquids and gases. Electric ball Control valves provide the accuracy and reliability needed to ensure consistent product quality and compliance with regulatory standards.

In power generation plants, Electric ball Control valves are used to control the flow of steam, water, and other fluids. Their ability to withstand high temperatures and pressures makes them suitable for use in boilers, turbines, and cooling systems.

Electric ball Control valves offer numerous advantages, including precision control, automation capabilities, durability, energy efficiency, and low maintenance. These benefits make them indispensable in a wide range of applications across various industries, from water treatment and chemical processing to oil and gas and HVAC systems. As technology advances, Electric ball Control valves are expected to become even more integral to modern industrial operations, providing enhanced performance and reliability.