The pneumatic diaphragm single-seat control valve is a vital component in industrial automation systems, designed to regulate fluid flow efficiently and precisely. Powered by compressed air, the valve uses a diaphragm to transfer force to the stem, which controls the movement of a globe valve. This mechanism ensures seamless control of fluid mediums within pipelines, making it indispensable for industries requiring reliable and accurate flow management.

Typically, these valves are equipped with essential accessories such as valve positioners, converters, and solenoid valves. These accessories enhance the valve’s functionality, enabling either on-off control or proportional regulation based on signals from an industrial automation control system. This adaptability allows the valve to meet diverse operational needs.

Pneumatic diaphragm single-seat control valves offer a host of features that make them a preferred choice for industrial applications:

The valve's small size and reduced weight simplify installation and minimize space requirements, particularly in compact system configurations.

Engineered for superior performance, these valves handle high-capacity operations efficiently, ensuring optimal system throughput.

Designed to meet general regulating valve standards set by the International Electrotechnical Commission (IEC), these valves ensure compatibility and reliability in diverse industrial settings.

Suitable for various fluid mediums and process conditions, the valve's versatility makes it an ideal solution for production process systems in multiple industries.

Featuring a pneumatic multi-spring diaphragm actuator, these valves are lightweight, easy to install, and straightforward to calibrate. The advanced actuator ensures smooth operation and precise control.

The valve body incorporates a low-flow resistance channel based on fluid mechanics principles, increasing the rated flow coefficient by 30%. This design enables smoother fluid movement and enhances system efficiency.

As industrial automation continues to evolve, the role of control valves, particularly pneumatic diaphragm valves, has become increasingly critical. Serving as the final actuators in automatic control systems, these valves directly influence the quality, efficiency, and safety of production processes. Their widespread adoption stems from key attributes such as:

The straightforward construction of pneumatic diaphragm valves makes them easy to use and maintain, reducing operational downtime.

Unlike other control valves, pneumatic diaphragm valves operate safely under various conditions, minimizing risks during operation.

From simple fluid control to complex industrial processes, these valves are versatile enough to handle numerous applications effectively.

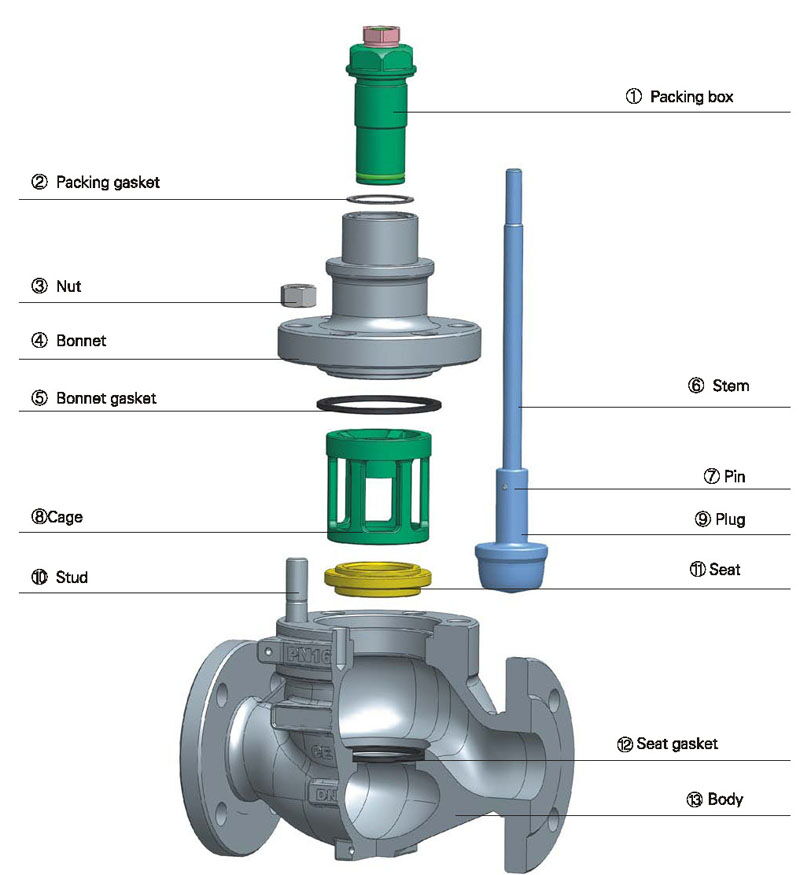

The top-guided single-seat design of these valves brings several advantages:

With fewer components, these valves are easier to maintain, ensuring long-term reliability and reducing the likelihood of mechanical failure.

Whether you’re managing high-pressure pipelines in the oil and gas sector, controlling sensitive fluids in chemical processing, or optimizing HVAC systems, these valves provide a robust solution that meets the demands of today’s complex industrial environments. With their compact design, superior flow characteristics, and intrinsic safety features, pneumatic diaphragm single-seat control valves continue to set the standard for excellence in flow management.