Pneumatic Globe Control Valves are essential components in various industrial systems, offering precise control over the flow rate, speed, and pressure of fluids. These valves are equipped with pneumatic actuators, which utilize feedback and control signals to adjust the valve's position, allowing for optimal fluid regulation. This article delves into the working principles, components, and key considerations when selecting and maintaining a Pneumatic Globe Control Valve.

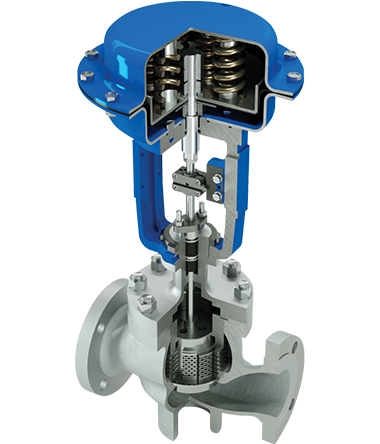

The globe valve body serves as the central component of the valve, directly interacting with the pressurized fluid within the system. It is where the valve’s internals, including the valve stem, disc, and seat, are housed. Typically, globe valve bodies are designed as two-port valves, where the inlet and outlet are positioned either directly opposite one another or at a 90° angle, as seen in angle globe valves.

Globe valves are known for their ability to handle challenging conditions, such as high-pressure, high-temperature, and corrosive or viscous fluids. When installed on horizontal pipelines, globe valves can accumulate residual fluids in the valve body if left unused for an extended period, leading to potential clogging or corrosion. To mitigate this issue, angle or oblique globe valves can be used, ensuring proper drainage of fluids when the valve is not in operation.

The materials used in constructing the globe valve body are critical to its performance and durability. Commonly used materials include heat-resistant alloys such as cast iron, stainless steel, and carbon steel, which provide resistance to the harsh operating conditions typically encountered in industries like chemical processing, oil and gas, and power generation.

Pneumatic actuators are integral to the operation of Pneumatic Globe Control Valves, providing the mechanical force needed to open and close the valve. There are two primary types of pneumatic actuators: piston actuators and diaphragm actuators. Unlike actuators for other types of valves, such as ball valves or butterfly valves, which employ rotary motion, pneumatic actuators for globe valves use a sliding motion to move the valve's internal components.

In piston-type actuators, compressed air is used to force the piston up or down, driving the valve stem to adjust the position of the valve's internal parts. Diaphragm actuators, on the other hand, use the pressure differential between the pneumatic supply and the diaphragm to achieve a similar motion. Both types of actuators provide precise control over the valve's position, ensuring that fluid flow, pressure, and temperature can be accurately regulated.

The Pneumatic Globe Control Valve operates based on the principles of fluid dynamics and pneumatic control. When the actuator receives a control signal, typically from a process controller or a supervisory control system, it activates the valve’s internal mechanism, moving the valve’s spool or plug up and down. This motion regulates the flow of fluid through the valve, either increasing or decreasing the flow rate, pressure, or temperature based on the desired setpoint.

The actuator uses compressed air as the power source, which is controlled by a series of feedback mechanisms that allow for precise adjustments. As the actuator adjusts the valve’s position, sensors or transmitters continuously monitor the process variables, such as flow rate or pressure, and send this information back to the control system. This feedback loop ensures that the valve maintains the correct position, delivering highly accurate control over the fluid system.

Selecting the correct Pneumatic Globe Control Valve for a given application is crucial to ensuring optimal performance and efficiency. Several factors must be considered when making this decision:

The material of the valve body plays a significant role in its durability and resistance to the fluid being controlled. Stainless steel is ideal for corrosive and high-temperature media, offering exceptional resistance to corrosion and erosion. For general-purpose applications, cast iron may be more suitable due to its cost-effectiveness and reliability in less demanding environments.

Pneumatic actuators come in two primary configurations: single-acting and double-acting. Single-acting actuators are designed for emergency shut-off scenarios where rapid closure of the valve is required. Double-acting actuators, on the other hand, are better suited for applications that require frequent opening and closing of the valve, as they provide more consistent and reliable operation over time.

The specific requirements of the application should guide the selection of the valve. Key parameters include the desired flow range, operating temperature, and pressure ratings. These factors determine the valve’s capacity to handle the system’s operating conditions and ensure reliable performance.

Proper installation and regular maintenance are essential to ensure that Pneumatic Globe Control Valves operate efficiently and last for their expected lifespan.

Centering the Valve: It is essential to ensure that the valve is properly centered within the pipeline to prevent misalignment, which can lead to leakage and improper sealing. Misalignment can also cause unnecessary wear on the valve components, reducing its lifespan.

Flow Direction: Always ensure that the flow direction of the fluid corresponds with the markings on the valve body. Incorrect installation can lead to poor performance and potential damage to the valve.

Regular maintenance helps prevent the buildup of debris or corrosion within the valve, ensuring smooth operation:

Cleaning: Periodically clean the valve spool and seat to remove any deposits or contaminants that could obstruct the valve’s movement. Accumulated debris can cause the valve to become stuck, resulting in unreliable performance.

Lubrication: Lubricate the moving parts of the actuator to reduce friction and wear. This helps extend the lifespan of the valve and actuator.

Like any mechanical system, Pneumatic Globe Control Valves may encounter issues during operation. Common problems include:

Actuator Failure: If the actuator fails to operate correctly, the first step is to check the pneumatic air supply. Ensure that the air pressure is within the required range and that the signal connections are properly configured. A drop in air pressure or an issue with the signal connection can prevent the actuator from functioning as intended.

Leaking Valve: If the valve is leaking, inspect the valve seat and seal for signs of wear or damage. A worn-out seal may need to be replaced to restore proper sealing performance.

Pneumatic Globe Control Valves are versatile and reliable components used across a wide range of industries to regulate fluid flow, pressure, and temperature. By understanding the key components and working principles, as well as considering factors like valve material, actuator type, and operational parameters, companies can make informed decisions about valve selection and maintenance. Regular installation checks and proactive maintenance practices ensure the longevity and optimal performance of these critical control valves, making them an indispensable part of modern industrial systems.