Temperature Control Valves: Types, Functions, and Selection Tips

On this page

In industrial applications where precise temperature regulation is critical, temperature control valves (TCVs) are indispensable components. These specialized valves play a crucial role in maintaining specific temperature ranges for various processes, which helps ensure operational efficiency, product quality, and equipment longevity. Used in everything from compressors and engine cooling systems to cogeneration applications, temperature control valves enable facilities to optimize temperature-sensitive processes. This article provides a comprehensive overview of temperature control valves, covering their purpose, types, and the key considerations for selecting the most suitable valve for any application.

A temperature control valve, often referred to as a temperature regulator, is designed to manage and maintain the temperature of fluids—whether liquids or gases—within a controlled range. Although similar to other control valves, temperature control valves are unique because they specifically focus on managing temperature rather than pressure or flow. In applications like engine jacket water cooling or turbine temperature regulation, TCVs work by adjusting fluid flow to ensure the desired temperature is achieved and maintained.

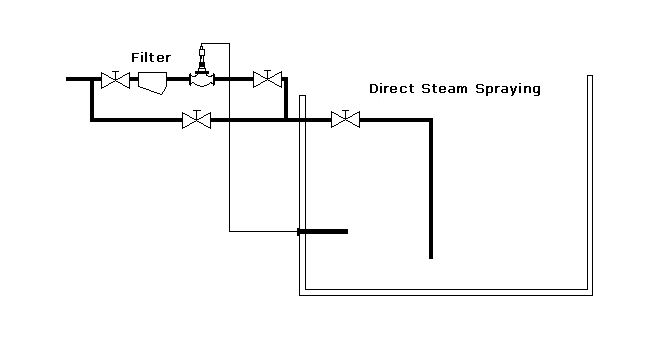

These valves are categorized based on the number of ports they feature. For instance, a valve with two ports is known as a 2-way valve, while a valve with three ports is termed a 3-way valve. Depending on the process requirements, TCVs can be used to either blend fluids at different temperatures or to direct flows in a way that keeps the process temperature stable. This level of control is critical in a wide array of industries, including energy production, chemical processing, and HVAC systems. Temperature control valves come in several designs, each suited for different types of temperature regulation tasks. Below is an overview of the most common types: Direct-acting temperature valves operate based on simple mechanical principles. They respond to changes in temperature without external power sources, making them a reliable and energy-efficient option for many applications. Typically, these valves contain wax or liquid-filled actuators that expand or contract in response to temperature changes, which moves the valve to control fluid flow and maintain the desired temperature.

These valves are categorized based on the number of ports they feature. For instance, a valve with two ports is known as a 2-way valve, while a valve with three ports is termed a 3-way valve. Depending on the process requirements, TCVs can be used to either blend fluids at different temperatures or to direct flows in a way that keeps the process temperature stable. This level of control is critical in a wide array of industries, including energy production, chemical processing, and HVAC systems. Temperature control valves come in several designs, each suited for different types of temperature regulation tasks. Below is an overview of the most common types: Direct-acting temperature valves operate based on simple mechanical principles. They respond to changes in temperature without external power sources, making them a reliable and energy-efficient option for many applications. Typically, these valves contain wax or liquid-filled actuators that expand or contract in response to temperature changes, which moves the valve to control fluid flow and maintain the desired temperature.