What Is an Explosion-Proof Electric Wafer Type Butterfly Valve?

On this page

Explosion-proof electric wafer type butterfly valves are engineered to safely control fluid flow in environments with a high risk of explosion due to the presence of flammable gases or vapors. These specialized valves are designed with robust features and stringent safety measures to prevent ignition and mitigate explosion risks.

Explosion-proof electric wafer type butterfly valves are crucial in industries where safety and reliability are paramount. Their design integrates both mechanical robustness and electrical safety, ensuring they perform effectively in hazardous environments. These valves are a key component in maintaining operational integrity while safeguarding against potential dangers.

Enhanced Safety: The primary advantage of explosion-proof electric wafer type butterfly valves is their ability to operate safely in explosive atmospheres. They are constructed to meet rigorous safety standards that prevent sparks or electrical faults that could lead to an explosion. This makes them indispensable in industries such as petrochemicals, mining, and pharmaceuticals.

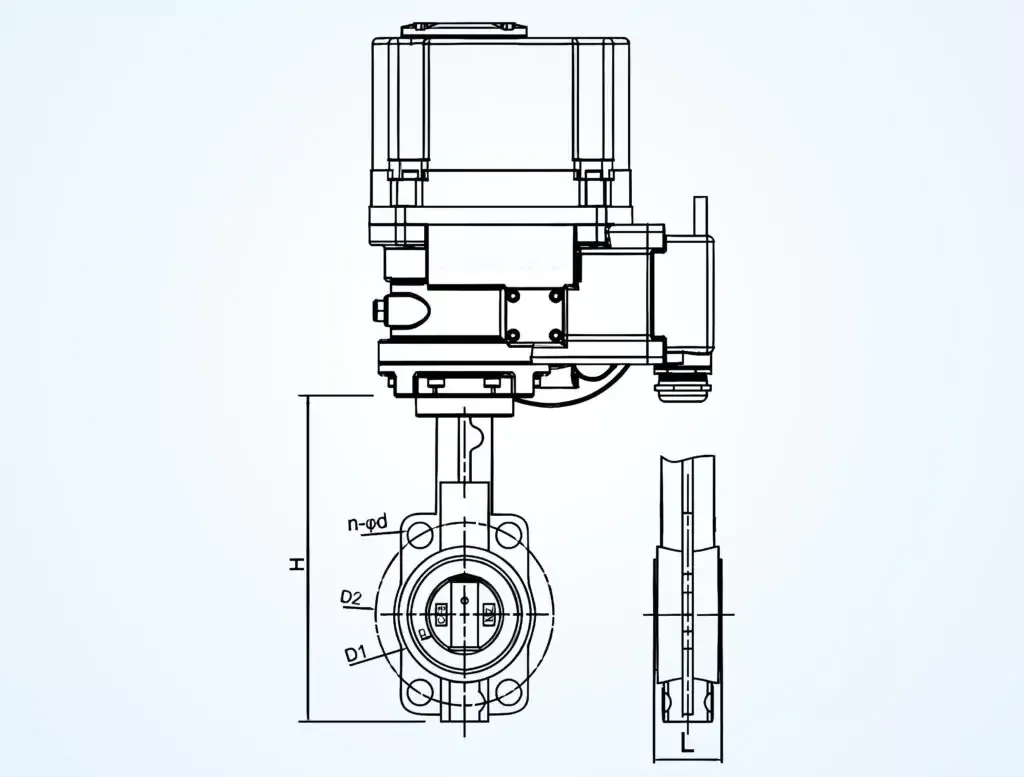

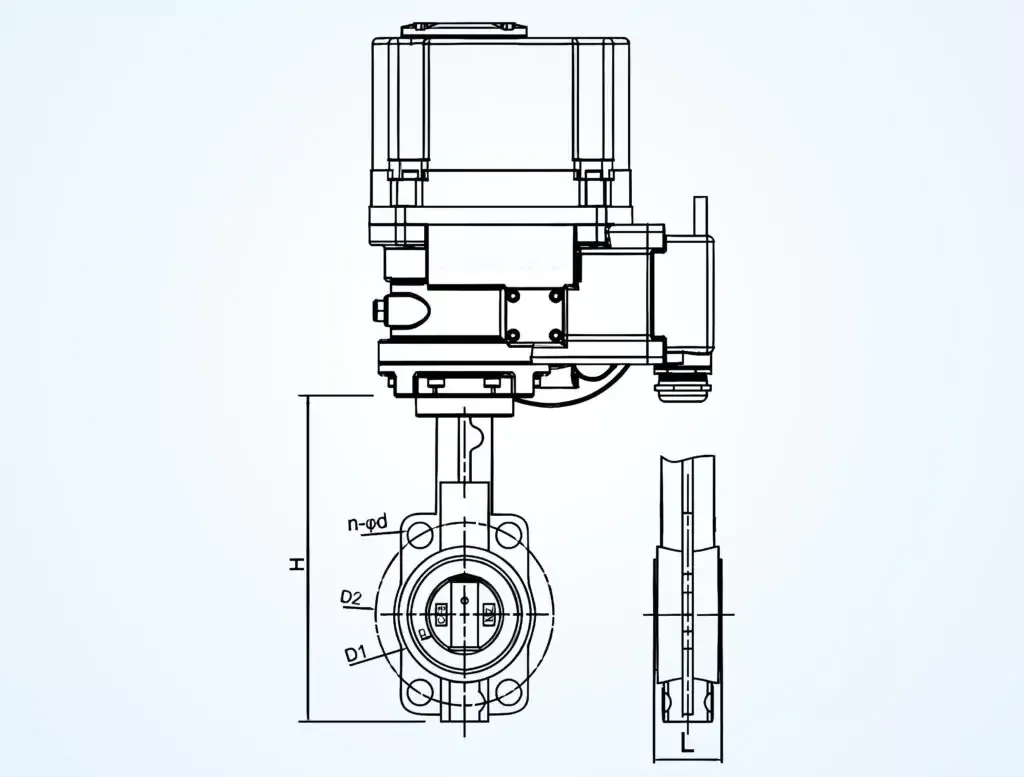

These valves are designed to be lightweight and compact. Their wafer type construction allows them to fit into tight spaces where traditional valve designs might be impractical. This compactness also reduces the overall weight of the system, which is beneficial in applications with weight constraints.

The wafer design simplifies installation by allowing the valve to be easily sandwiched between flanges, reducing the need for additional fittings or adapters. Maintenance is also straightforward due to the valve's modular design, which can often be serviced or replaced without extensive disassembly.

Electric actuation provides precise control over the valve's operation. This allows for accurate modulation of fluid flow, enhancing process control and operational efficiency. The electric actuator can be integrated with control systems for automated operations, further improving reliability and reducing the need for manual intervention.

Constructed from high-quality materials, these valves are built to withstand harsh conditions and provide long-term service. Their robust design ensures they remain functional and reliable even in challenging environments.

Petrochemical Industry: In the petrochemical sector, these valves are used in processes where flammable gases and vapors are present. Their explosion-proof design ensures safe operation in refineries and chemical plants, where the risk of explosion is significant.

Mining environments often involve the handling of explosive materials and gases. Explosion-proof electric wafer type butterfly valves are used to control fluid flow in mining equipment and infrastructure, ensuring safety and operational efficiency.

The pharmaceutical industry also benefits from these valves, particularly in processes where explosive or reactive substances are handled. The explosion-proof feature ensures that operations are carried out safely without the risk of ignition.

In oil and gas operations, where the presence of flammable substances is a constant concern, these valves play a critical role in maintaining safety. They are used in pipelines, storage tanks, and other equipment to control the flow of fluids and gases safely.

Various industrial processes involve the handling of hazardous materials that could potentially cause explosions. The explosion-proof electric wafer type butterfly valves provide a reliable solution for controlling flow in such environments, ensuring that operations proceed without incident.

Explosion-proof electric wafer type butterfly valves represent a vital advancement in valve technology, offering enhanced safety and reliability for operations in hazardous environments. Their compact design, robust construction, and precise control capabilities make them an ideal choice for industries where the risk of explosion is a significant concern. By integrating stringent safety measures with advanced electric actuation, these valves ensure both operational efficiency and protection against potential dangers, reinforcing their indispensable role in modern industrial processes.

Enhanced Safety: The primary advantage of explosion-proof electric wafer type butterfly valves is their ability to operate safely in explosive atmospheres. They are constructed to meet rigorous safety standards that prevent sparks or electrical faults that could lead to an explosion. This makes them indispensable in industries such as petrochemicals, mining, and pharmaceuticals.

These valves are designed to be lightweight and compact. Their wafer type construction allows them to fit into tight spaces where traditional valve designs might be impractical. This compactness also reduces the overall weight of the system, which is beneficial in applications with weight constraints.

The wafer design simplifies installation by allowing the valve to be easily sandwiched between flanges, reducing the need for additional fittings or adapters. Maintenance is also straightforward due to the valve's modular design, which can often be serviced or replaced without extensive disassembly.

Electric actuation provides precise control over the valve's operation. This allows for accurate modulation of fluid flow, enhancing process control and operational efficiency. The electric actuator can be integrated with control systems for automated operations, further improving reliability and reducing the need for manual intervention.

Constructed from high-quality materials, these valves are built to withstand harsh conditions and provide long-term service. Their robust design ensures they remain functional and reliable even in challenging environments.

Petrochemical Industry: In the petrochemical sector, these valves are used in processes where flammable gases and vapors are present. Their explosion-proof design ensures safe operation in refineries and chemical plants, where the risk of explosion is significant.

Mining environments often involve the handling of explosive materials and gases. Explosion-proof electric wafer type butterfly valves are used to control fluid flow in mining equipment and infrastructure, ensuring safety and operational efficiency.

The pharmaceutical industry also benefits from these valves, particularly in processes where explosive or reactive substances are handled. The explosion-proof feature ensures that operations are carried out safely without the risk of ignition.

In oil and gas operations, where the presence of flammable substances is a constant concern, these valves play a critical role in maintaining safety. They are used in pipelines, storage tanks, and other equipment to control the flow of fluids and gases safely.

Various industrial processes involve the handling of hazardous materials that could potentially cause explosions. The explosion-proof electric wafer type butterfly valves provide a reliable solution for controlling flow in such environments, ensuring that operations proceed without incident.

Explosion-proof electric wafer type butterfly valves represent a vital advancement in valve technology, offering enhanced safety and reliability for operations in hazardous environments. Their compact design, robust construction, and precise control capabilities make them an ideal choice for industries where the risk of explosion is a significant concern. By integrating stringent safety measures with advanced electric actuation, these valves ensure both operational efficiency and protection against potential dangers, reinforcing their indispensable role in modern industrial processes.

As industries continue to prioritize safety and efficiency, explosion-proof electric wafer type butterfly valves will remain a crucial component in safeguarding operations and maintaining the integrity of hazardous environments.

Explosion-proof electric wafer type butterfly valves are crucial in industries where safety and reliability are paramount. Their design integrates both mechanical robustness and electrical safety, ensuring they perform effectively in hazardous environments. These valves are a key component in maintaining operational integrity while safeguarding against potential dangers.

Enhanced Safety: The primary advantage of explosion-proof electric wafer type butterfly valves is their ability to operate safely in explosive atmospheres. They are constructed to meet rigorous safety standards that prevent sparks or electrical faults that could lead to an explosion. This makes them indispensable in industries such as petrochemicals, mining, and pharmaceuticals.

These valves are designed to be lightweight and compact. Their wafer type construction allows them to fit into tight spaces where traditional valve designs might be impractical. This compactness also reduces the overall weight of the system, which is beneficial in applications with weight constraints.

The wafer design simplifies installation by allowing the valve to be easily sandwiched between flanges, reducing the need for additional fittings or adapters. Maintenance is also straightforward due to the valve's modular design, which can often be serviced or replaced without extensive disassembly.

Electric actuation provides precise control over the valve's operation. This allows for accurate modulation of fluid flow, enhancing process control and operational efficiency. The electric actuator can be integrated with control systems for automated operations, further improving reliability and reducing the need for manual intervention.

Constructed from high-quality materials, these valves are built to withstand harsh conditions and provide long-term service. Their robust design ensures they remain functional and reliable even in challenging environments.

Petrochemical Industry: In the petrochemical sector, these valves are used in processes where flammable gases and vapors are present. Their explosion-proof design ensures safe operation in refineries and chemical plants, where the risk of explosion is significant.

Mining environments often involve the handling of explosive materials and gases. Explosion-proof electric wafer type butterfly valves are used to control fluid flow in mining equipment and infrastructure, ensuring safety and operational efficiency.

The pharmaceutical industry also benefits from these valves, particularly in processes where explosive or reactive substances are handled. The explosion-proof feature ensures that operations are carried out safely without the risk of ignition.

In oil and gas operations, where the presence of flammable substances is a constant concern, these valves play a critical role in maintaining safety. They are used in pipelines, storage tanks, and other equipment to control the flow of fluids and gases safely.

Various industrial processes involve the handling of hazardous materials that could potentially cause explosions. The explosion-proof electric wafer type butterfly valves provide a reliable solution for controlling flow in such environments, ensuring that operations proceed without incident.

Explosion-proof electric wafer type butterfly valves represent a vital advancement in valve technology, offering enhanced safety and reliability for operations in hazardous environments. Their compact design, robust construction, and precise control capabilities make them an ideal choice for industries where the risk of explosion is a significant concern. By integrating stringent safety measures with advanced electric actuation, these valves ensure both operational efficiency and protection against potential dangers, reinforcing their indispensable role in modern industrial processes.

Enhanced Safety: The primary advantage of explosion-proof electric wafer type butterfly valves is their ability to operate safely in explosive atmospheres. They are constructed to meet rigorous safety standards that prevent sparks or electrical faults that could lead to an explosion. This makes them indispensable in industries such as petrochemicals, mining, and pharmaceuticals.

These valves are designed to be lightweight and compact. Their wafer type construction allows them to fit into tight spaces where traditional valve designs might be impractical. This compactness also reduces the overall weight of the system, which is beneficial in applications with weight constraints.

The wafer design simplifies installation by allowing the valve to be easily sandwiched between flanges, reducing the need for additional fittings or adapters. Maintenance is also straightforward due to the valve's modular design, which can often be serviced or replaced without extensive disassembly.

Electric actuation provides precise control over the valve's operation. This allows for accurate modulation of fluid flow, enhancing process control and operational efficiency. The electric actuator can be integrated with control systems for automated operations, further improving reliability and reducing the need for manual intervention.

Constructed from high-quality materials, these valves are built to withstand harsh conditions and provide long-term service. Their robust design ensures they remain functional and reliable even in challenging environments.

Petrochemical Industry: In the petrochemical sector, these valves are used in processes where flammable gases and vapors are present. Their explosion-proof design ensures safe operation in refineries and chemical plants, where the risk of explosion is significant.

Mining environments often involve the handling of explosive materials and gases. Explosion-proof electric wafer type butterfly valves are used to control fluid flow in mining equipment and infrastructure, ensuring safety and operational efficiency.

The pharmaceutical industry also benefits from these valves, particularly in processes where explosive or reactive substances are handled. The explosion-proof feature ensures that operations are carried out safely without the risk of ignition.

In oil and gas operations, where the presence of flammable substances is a constant concern, these valves play a critical role in maintaining safety. They are used in pipelines, storage tanks, and other equipment to control the flow of fluids and gases safely.

Various industrial processes involve the handling of hazardous materials that could potentially cause explosions. The explosion-proof electric wafer type butterfly valves provide a reliable solution for controlling flow in such environments, ensuring that operations proceed without incident.

Explosion-proof electric wafer type butterfly valves represent a vital advancement in valve technology, offering enhanced safety and reliability for operations in hazardous environments. Their compact design, robust construction, and precise control capabilities make them an ideal choice for industries where the risk of explosion is a significant concern. By integrating stringent safety measures with advanced electric actuation, these valves ensure both operational efficiency and protection against potential dangers, reinforcing their indispensable role in modern industrial processes.As industries continue to prioritize safety and efficiency, explosion-proof electric wafer type butterfly valves will remain a crucial component in safeguarding operations and maintaining the integrity of hazardous environments.