Why Choose a Butterfly Valve for Flow Control?

On this page

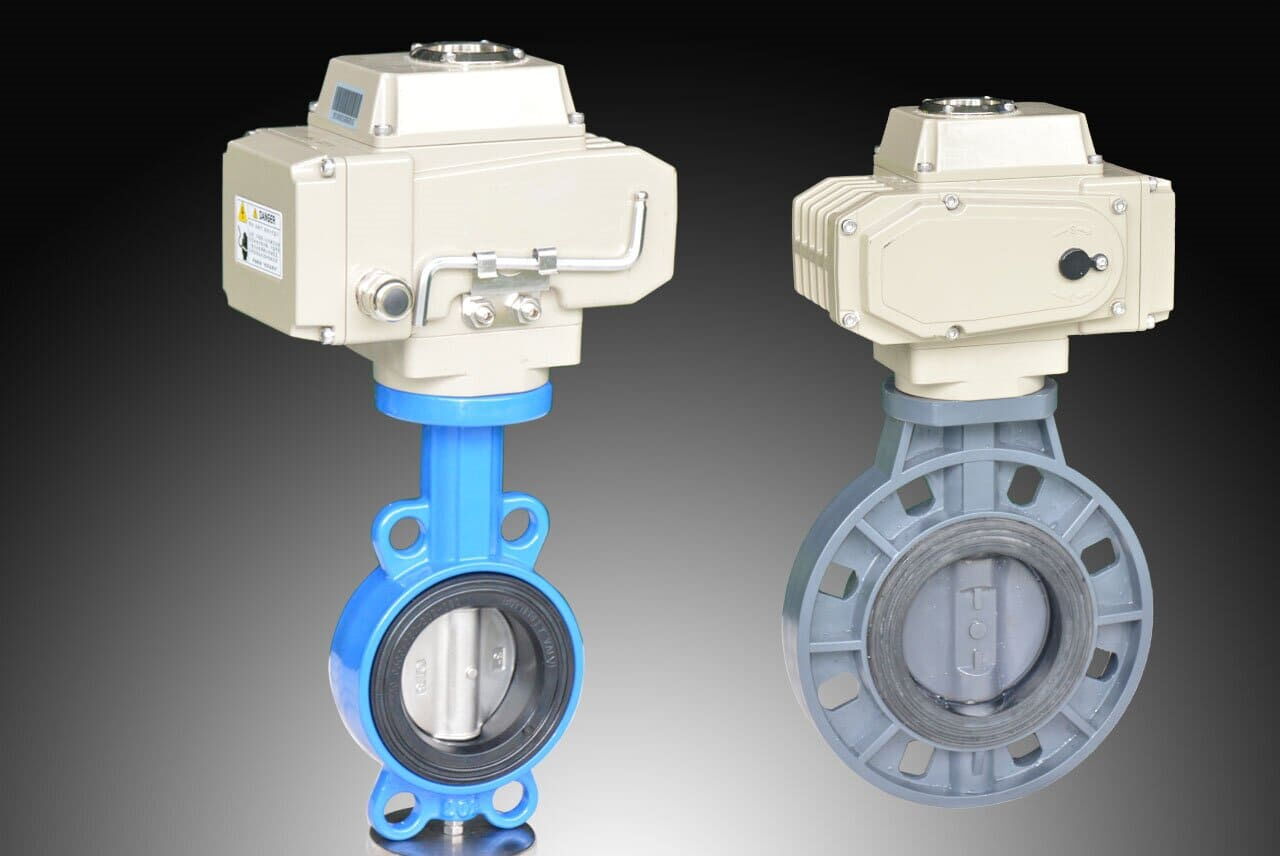

In industrial applications, selecting the right valve for flow control is crucial. Among the wide variety of valves available, butterfly valves stand out as a versatile, efficient, and cost-effective option. Whether for regulating fluid flow or ensuring complete shutoff, butterfly valves offer significant advantages in numerous industries. This article explores the key reasons why butterfly valves are a top choice for flow control applications.

Butterfly valves are designed for simplicity and efficiency, providing several advantages over other valve types. Their structure, cost-effectiveness, and performance make them ideal for a range of uses, from water treatment plants to chemical processing facilities.

One of the most notable features of butterfly valves is their compact and lightweight design. Unlike gate or globe valves, butterfly valves require less space and are easier to install due to their streamlined profile. This space-saving attribute makes them an excellent choice for applications where minimizing footprint is essential, such as in tight piping systems or portable equipment.

Butterfly valves are designed for simplicity and efficiency, providing several advantages over other valve types. Their structure, cost-effectiveness, and performance make them ideal for a range of uses, from water treatment plants to chemical processing facilities.

One of the most notable features of butterfly valves is their compact and lightweight design. Unlike gate or globe valves, butterfly valves require less space and are easier to install due to their streamlined profile. This space-saving attribute makes them an excellent choice for applications where minimizing footprint is essential, such as in tight piping systems or portable equipment.

The lightweight nature of butterfly valves also reduces the need for extensive support structures, lowering installation and maintenance costs. This benefit is especially valuable in larger valve sizes, where the reduced weight can significantly impact the overall system design and budget. When compared to other types of flow control valves, butterfly valves are highly cost-effective. Their straightforward design and fewer components result in lower production costs, which in turn reduces the initial purchase price. In addition, butterfly valves require less maintenance due to their robust and simple construction, which helps reduce long-term operational expenses.

Furthermore, because butterfly valves have fewer moving parts, the likelihood of mechanical failure is minimized, lowering the need for repairs or replacements. This aspect contributes to a lower total cost of ownership, making butterfly valves an attractive choice for budget-conscious operations. Butterfly valves excel at providing high-performance flow regulation. Their design allows for precise control over the flow rate of various fluids, including water, gas, and chemicals. The valve’s quick response time and ability to modulate flow efficiently make it an excellent option for systems that require dynamic flow control.

In addition, butterfly valves exhibit low flow resistance, meaning they create minimal pressure drop when open. This characteristic helps maintain energy efficiency across the system, reducing the overall energy required to operate the valve. For industries aiming to optimize flow while conserving energy, butterfly valves offer a highly effective solution. Durability and reliability are crucial factors when selecting a valve for long-term operation, and butterfly valves deliver on both fronts. Built with high-quality materials such as stainless steel, cast iron, or resilient polymers, butterfly valves can withstand harsh operating conditions, including high temperatures, pressures, and corrosive environments.

The valve's double offset (also known as double eccentric) design is a key feature that enhances its durability. This design reduces friction and wear between the disc and seat during operation, extending the valve's service life. As a result, butterfly valves are ideal for applications that demand frequent cycling or where reliability is paramount.

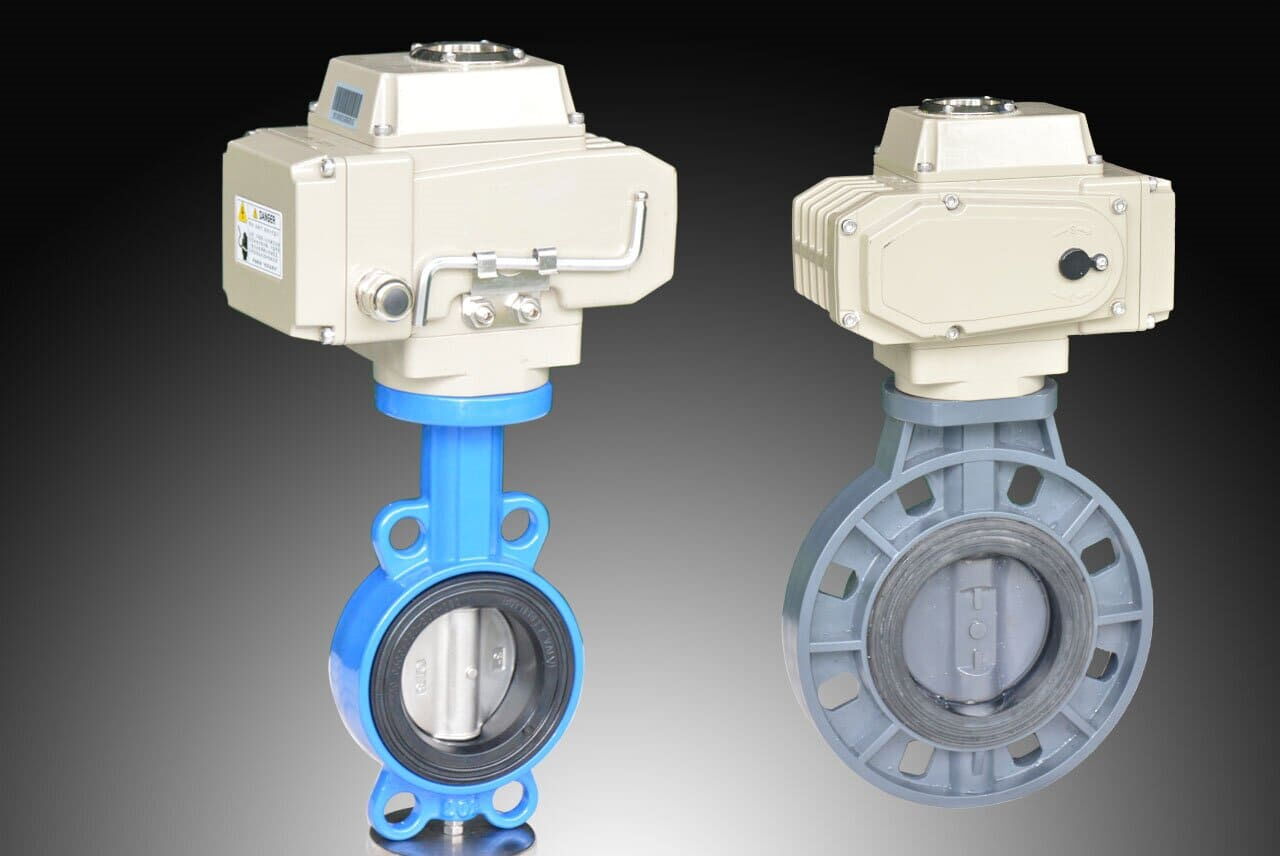

Additionally, butterfly valves are available in both soft-seated and metal-seated configurations, offering versatility in different working conditions. Whether used in high-temperature processes or applications that require tight sealing, butterfly valves are built to last. Butterfly valves offer remarkable versatility across various applications and industries. They can be used for both on/off functions and flow regulation, making them suitable for a wide range of fluid types, including liquids, gases, and slurries. This versatility makes butterfly valves a practical choice for sectors like oil and gas, water treatment, HVAC, and food processing.

From an environmental standpoint, butterfly valves contribute to sustainability by reducing the energy required for operation. Their low flow resistance and efficient design help conserve energy, resulting in lower greenhouse gas emissions over time. Furthermore, many butterfly valves are designed to minimize leakage, reducing the risk of environmental contamination. A common question in the valve industry is whether butterfly valves can effectively serve as control valves. The answer is yes, but with certain caveats. Butterfly valves are primarily designed for on/off applications; however, they can be adapted for flow control when equipped with an appropriate actuator or manual operator.

When used as control valves, butterfly valves can modulate flow rates accurately, making them suitable for systems that require throttling. The double offset design also plays a role here, allowing for smooth modulation with minimal wear and tear. However, for highly precise flow control or systems requiring extremely tight tolerances, other valve types like globe valves may be more suitable.

In applications where precision is not the primary concern, butterfly valves perform exceptionally well as control valves. Their cost-effectiveness, compact design, and quick response make them a popular choice for industries looking to balance performance with budget considerations. Butterfly valves are a smart choice for flow control due to their compact design, cost-efficiency, high performance, durability, and versatility. Their ability to regulate fluid flow while providing long-lasting reliability makes them an ideal solution for a wide range of industries. In addition, their environmentally friendly attributes make them a sustainable option in an increasingly energy-conscious world. While butterfly valves may not always be the first choice for precision control, they remain a highly effective and affordable solution for general flow control applications.

For industries looking for a valve that offers both performance and value, butterfly valves stand out as one of the best options available.

Butterfly valves are designed for simplicity and efficiency, providing several advantages over other valve types. Their structure, cost-effectiveness, and performance make them ideal for a range of uses, from water treatment plants to chemical processing facilities.

One of the most notable features of butterfly valves is their compact and lightweight design. Unlike gate or globe valves, butterfly valves require less space and are easier to install due to their streamlined profile. This space-saving attribute makes them an excellent choice for applications where minimizing footprint is essential, such as in tight piping systems or portable equipment.

Butterfly valves are designed for simplicity and efficiency, providing several advantages over other valve types. Their structure, cost-effectiveness, and performance make them ideal for a range of uses, from water treatment plants to chemical processing facilities.

One of the most notable features of butterfly valves is their compact and lightweight design. Unlike gate or globe valves, butterfly valves require less space and are easier to install due to their streamlined profile. This space-saving attribute makes them an excellent choice for applications where minimizing footprint is essential, such as in tight piping systems or portable equipment.The lightweight nature of butterfly valves also reduces the need for extensive support structures, lowering installation and maintenance costs. This benefit is especially valuable in larger valve sizes, where the reduced weight can significantly impact the overall system design and budget. When compared to other types of flow control valves, butterfly valves are highly cost-effective. Their straightforward design and fewer components result in lower production costs, which in turn reduces the initial purchase price. In addition, butterfly valves require less maintenance due to their robust and simple construction, which helps reduce long-term operational expenses.

Furthermore, because butterfly valves have fewer moving parts, the likelihood of mechanical failure is minimized, lowering the need for repairs or replacements. This aspect contributes to a lower total cost of ownership, making butterfly valves an attractive choice for budget-conscious operations. Butterfly valves excel at providing high-performance flow regulation. Their design allows for precise control over the flow rate of various fluids, including water, gas, and chemicals. The valve’s quick response time and ability to modulate flow efficiently make it an excellent option for systems that require dynamic flow control.

In addition, butterfly valves exhibit low flow resistance, meaning they create minimal pressure drop when open. This characteristic helps maintain energy efficiency across the system, reducing the overall energy required to operate the valve. For industries aiming to optimize flow while conserving energy, butterfly valves offer a highly effective solution. Durability and reliability are crucial factors when selecting a valve for long-term operation, and butterfly valves deliver on both fronts. Built with high-quality materials such as stainless steel, cast iron, or resilient polymers, butterfly valves can withstand harsh operating conditions, including high temperatures, pressures, and corrosive environments.

The valve's double offset (also known as double eccentric) design is a key feature that enhances its durability. This design reduces friction and wear between the disc and seat during operation, extending the valve's service life. As a result, butterfly valves are ideal for applications that demand frequent cycling or where reliability is paramount.

Additionally, butterfly valves are available in both soft-seated and metal-seated configurations, offering versatility in different working conditions. Whether used in high-temperature processes or applications that require tight sealing, butterfly valves are built to last. Butterfly valves offer remarkable versatility across various applications and industries. They can be used for both on/off functions and flow regulation, making them suitable for a wide range of fluid types, including liquids, gases, and slurries. This versatility makes butterfly valves a practical choice for sectors like oil and gas, water treatment, HVAC, and food processing.

From an environmental standpoint, butterfly valves contribute to sustainability by reducing the energy required for operation. Their low flow resistance and efficient design help conserve energy, resulting in lower greenhouse gas emissions over time. Furthermore, many butterfly valves are designed to minimize leakage, reducing the risk of environmental contamination. A common question in the valve industry is whether butterfly valves can effectively serve as control valves. The answer is yes, but with certain caveats. Butterfly valves are primarily designed for on/off applications; however, they can be adapted for flow control when equipped with an appropriate actuator or manual operator.

When used as control valves, butterfly valves can modulate flow rates accurately, making them suitable for systems that require throttling. The double offset design also plays a role here, allowing for smooth modulation with minimal wear and tear. However, for highly precise flow control or systems requiring extremely tight tolerances, other valve types like globe valves may be more suitable.

In applications where precision is not the primary concern, butterfly valves perform exceptionally well as control valves. Their cost-effectiveness, compact design, and quick response make them a popular choice for industries looking to balance performance with budget considerations. Butterfly valves are a smart choice for flow control due to their compact design, cost-efficiency, high performance, durability, and versatility. Their ability to regulate fluid flow while providing long-lasting reliability makes them an ideal solution for a wide range of industries. In addition, their environmentally friendly attributes make them a sustainable option in an increasingly energy-conscious world. While butterfly valves may not always be the first choice for precision control, they remain a highly effective and affordable solution for general flow control applications.

For industries looking for a valve that offers both performance and value, butterfly valves stand out as one of the best options available.