Control valves are essential components in industrial fluid systems, ensuring precise regulation of flow rates, pressure, and direction. Among the various types of control valves, the eccentric plug control valve stands out due to its unique design and superior performance in handling challenging media such as slurries, viscous liquids, and abrasive fluids.

This article explores the working principle, key features, applications, and performance advantages of eccentric plug control valves, providing a comprehensive understanding of their role in modern industrial processes.

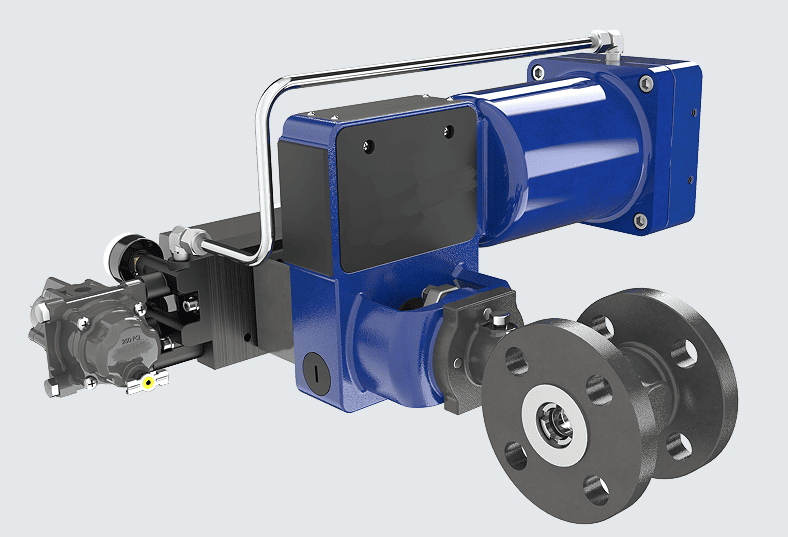

An eccentric plug control valve is a quarter-turn rotary valve designed for precise flow regulation in pipelines. Unlike conventional plug valves, which use a centered plug, this valve features an off-center (eccentric) plug that minimizes friction and wear during operation.

Eccentric Plug: The plug is offset from the valve seat, allowing it to lift away from the seat as it rotates, reducing wear.

Robust Construction: Made from durable materials (e.g., stainless steel, hardened alloys) to withstand harsh conditions.

Tight Shutoff: Provides a secure seal when closed, preventing leakage.

Self-Cleaning Action: The plug’s movement prevents debris buildup on the seat.

This design makes eccentric plug valves ideal for demanding applications, including oil and gas, chemical processing, power generation, and water treatment.

The eccentric plug control valve operates on a simple yet highly effective mechanism that ensures minimal friction, long service life, and precise flow control.

When the valve is closed, the eccentric plug is pressed firmly against the seat, creating a tight seal.

The off-center design ensures uniform sealing force, preventing leaks even under high pressure.

As the valve opens, the plug rotates away from the seat in a quarter-turn (90-degree) motion.

The eccentricity of the plug ensures it disengages from the seat immediately, reducing friction and wear.

This action allows fluid to flow smoothly through the valve body with minimal resistance.

The degree of rotation determines the flow rate—partial turns allow for fine-tuned regulation.

The straight-through flow path minimizes turbulence and pressure drop.

The rotating motion of the plug prevents particle buildup on the seat.

Abrasive-resistant materials enhance durability in slurry and viscous media applications.

Eccentric plug control valves offer several performance advantages over traditional globe or ball valves:

|

Feature |

Description |

|

Tight Shutoff |

Hard-seal variants meet ANSI B16.104 Class IV, while soft-seal versions achieve Class VI for zero leakage. |

|

Low Operating Torque |

The offset plug reduces friction, requiring less force to operate. |

|

Self-Cleaning Action |

Prevents clogging in slurry and high-solid-content applications. |

|

Extended Seat Life |

The inlet flow path is protected from erosion, enhancing durability. |

|

Split Spool Design |

Allows for custom material selection (e.g., corrosion-resistant alloys). |

|

One-Piece Stem Design |

Ensures rigidity and precise positioning for reliable sealing. |

|

Anti-Fly-Out Stem Shoulder |

Prevents stem ejection under high pressure for safety and reliability. |

|

Easy Maintenance |

Simplified design allows for quick disassembly and servicing. |

Due to their robust construction and precise control, these valves are widely used in:

Crude oil, refined petroleum, and natural gas transport

Resistant to high-pressure and corrosive fluids

Acids, alkalis, and abrasive chemical flows

Corrosion-resistant materials ensure long-term reliability

Boiler feedwater, steam control, and cooling systems

Handles high-temperature and high-pressure conditions

Sludge, slurry, and treated water flow regulation

Self-cleaning action prevents clogging in dirty water applications

Eccentric plug control valves outperform traditional globe and ball valves in several ways:

Straight-through flow path reduces turbulence and pressure drop.

Large adjustable ratio for precise flow control.

Extended seat design protects against erosion.

Hardened materials resist wear from abrasive media.

Self-cleaning mechanism minimizes seat damage.

Simple construction allows for easy servicing.

Anti-fly-out stem design prevents mechanical failure.

Leak-proof sealing ensures compliance with industry standards.

Selecting the ideal eccentric plug control valve requires careful evaluation of key factors to ensure reliable performance, durability, and efficiency in your system. Here are the most important considerations:

Choose corrosion-resistant materials (stainless steel, duplex steel, or special alloys) for chemical or acidic media.

For abrasive slurries, opt for hardened coatings or wear-resistant materials to extend valve life.

Verify the valve’s maximum pressure (PN/Class rating) and temperature limits to match your process conditions.

High-pressure applications may require reinforced body designs.

Match the valve size (DN/NPS) to your pipeline diameter to prevent excessive pressure drop or flow restriction.

Consider Cv (flow coefficient) for optimal control efficiency.

Manual valves are cost-effective for simple on/off applications.

Automated actuation (pneumatic, electric, or hydraulic) is ideal for remote control, precision throttling, or high-cycle operations.

Soft-seated valves (PTFE, elastomers) provide bubble-tight shutoff (ANSI Class VI) for critical applications.

Metal-seated valves are better for high-temperature or abrasive services.

Look for easy-access designs for quick maintenance.

Valves with self-cleaning seats reduce clogging in slurry applications.

By carefully evaluating these factors, you can select an eccentric plug valve that delivers long-lasting performance, minimal downtime, and cost-effective operation in your specific industrial process.

Eccentric plug control valves are high-performance solutions for industries requiring reliable, low-maintenance, and precise flow control. Their unique off-center plug design minimizes wear, enhances sealing, and extends service life, making them ideal for oil & gas, chemical processing, power plants, and water treatment systems.

By combining robust construction, self-cleaning action, and tight shutoff capabilities, these valves provide long-term efficiency and cost savings in demanding industrial environments.

For engineers and plant operators, selecting an eccentric plug control valve ensures optimal flow regulation, reduced downtime, and improved system performance.