In the world of industrial process control, achieving reliable valve performance hinges on more than just selecting the right control valve body or actuator. A frequently overlooked yet critical component in valve integrity and efficiency is the valve packing. While it may seem like a minor detail, the correct choice and installation of valve packing is essential to maintaining sealing performance, preventing fugitive emissions, and ensuring long-term operational safety.

Before diving into the criteria for selecting control valve packing, it's important to first understand what valve packing is, how it functions within different types of valves, and why it matters.

Control valves are typically categorized into two basic designs: sliding stem and rotary. A sliding stem valve includes a rod, or stem, that moves up and down through the valve body to regulate flow. A rotary valve, in contrast, utilizes a rotating shaft to control the position of a disc, ball, or plug. In both cases, the valve stem or shaft must pass through the valve body — creating a potential leak path.

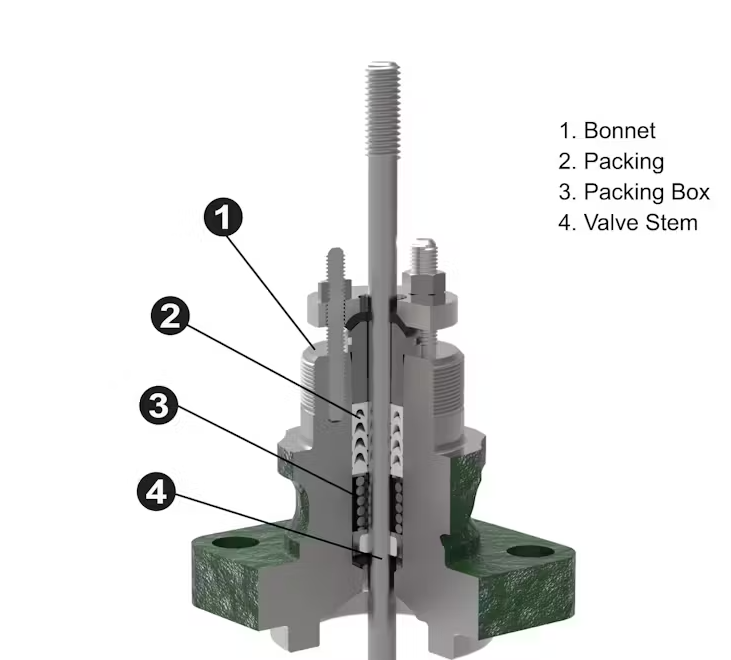

This is where valve packing comes into play. Packing is the sealing system located around the stem or shaft at the point where it exits the valve body. It prevents process media — whether it be gas, liquid, or vapor — from escaping to the environment while allowing the valve to operate with minimal friction and wear.

The sealing mechanism typically consists of stacked rings made of flexible materials such as PTFE (polytetrafluoroethylene) or graphite. These rings are compressed using a combination of a packing follower, packing flange, and bolts to create a tight seal against the valve stem or shaft. When correctly selected and maintained, packing can offer years of reliable, leak-free operation.

Different process conditions require different packing materials. The right choice depends on temperature, pressure, media type, environmental regulations, and maintenance needs. Below, we explore the most common types of packing materials used in industrial control valves.

PTFE — often known by the brand name Teflon — is a synthetic fluoropolymer with unique physical properties that make it a popular choice in many industrial applications. It is best known for its extremely low friction coefficient, high chemical resistance, and non-reactivity.

Chemical Inertness: PTFE is resistant to almost all chemicals, including strong acids, bases, and solvents. This makes it ideal for chemical plants and industries handling aggressive fluids.

Low Friction Operation: Its slippery surface reduces friction between the packing and valve stem, leading to smoother valve motion and reduced wear.

Moderate Temperature Tolerance: PTFE can function well in operating temperatures up to approximately 250°C (482°F), covering a broad range of moderate applications.

Non-Stick Properties: Its ability to resist sticking or bonding to valve stems makes it easier to adjust or remove, aiding in maintenance.

Limited High-Temperature Capability: At temperatures above 250°C, PTFE begins to degrade and may lose its mechanical properties.

Vulnerability to Creep and Cold Flow: Under constant pressure or heat cycling, PTFE can deform permanently over time, potentially compromising the seal.

Not Ideal for High-Pressure Steam Applications: While PTFE is chemically resilient, it may wear quickly in high-pressure or high-temperature steam environments, particularly if abrasive media are present.

Flexible graphite packing is widely used in high-temperature and high-pressure environments where PTFE is unsuitable. It is manufactured from exfoliated graphite flakes, which are pressed into ring shapes or braided into packing sets.

High-Temperature Resistance: Graphite can withstand temperatures up to 450°C (842°F) in oxidizing atmospheres and even higher in inert conditions — ideal for steam and hydrocarbon services.

Excellent Thermal Conductivity: This property helps to dissipate heat more efficiently, reducing stem damage and increasing packing lifespan.

Low Emissions: Graphite is a common choice for control valves in emission-critical services due to its ability to maintain tight seals under thermal cycling and stem movement.

Resilience Under Pressure: Flexible graphite performs well under extreme pressure without losing its sealing capabilities.

Chemical Sensitivity in Oxidizing Environments: Though graphite itself is carbon, it can oxidize at high temperatures in the presence of oxygen, potentially leading to degradation.

Abrasion and Stem Wear: Unlike PTFE, graphite is more abrasive and may cause wear on valve stems over time, especially if not properly coated or lubricated.

Cost: Graphite packing is typically more expensive than PTFE, although the investment is often justified by its superior high-temperature performance and durability.

For ultra-high-temperature or pressure applications, metallic or composite packing systems may be used. These typically incorporate layers of metal wire mesh, foil, or metal-reinforced graphite. Some applications also use metal spring-loaded packing systems, which maintain a consistent preload on the packing to ensure reliable sealing under thermal expansion and cycling.

Refineries and Power Plants: Where superheated steam or hydrocarbon vapors are present at extreme temperatures.

Nuclear Facilities: Where durability and zero-leakage standards are strict.

Severe Service Control Valves: Where vibration, cycling, and extreme thermal variations are common.

Installation Complexity: Metal-based packing requires careful installation and specialized tools. Improper installation can reduce performance or cause damage.

Stem Finish and Hardness: Because metallic materials can be abrasive, valve stems must have a high-quality surface finish and hardness to resist wear.

Choosing the right packing material is only part of the equation. Several other factors must be taken into account to ensure long-term valve performance and safety:

With increasing environmental regulations, particularly in chemical and petrochemical industries, control valve packing is expected to meet strict fugitive emissions standards such as ISO 15848 and API 622. Low-emission packing solutions, often made from flexible graphite or hybrid materials, are designed to minimize leakage to atmosphere.

The condition of the valve stem significantly impacts packing performance. A smoother surface finish reduces wear on packing materials, while a harder stem surface can resist abrasion — especially important when using graphite or metal packing.

Packing sets may come as preformed rings, braided sets, or die-molded shapes. The number of rings and their sequence (sealing rings, lantern rings, wipers) can influence both performance and maintenance requirements.

In high-cycle or critical applications, live-loading systems are used to automatically apply a constant load to the packing via springs or Belleville washers. This compensates for packing wear or thermal cycling, ensuring longer sealing life with less maintenance.

Even the best packing material will fail if not installed or maintained properly. Here are a few key practices:

Use the Correct Torque: Over-tightening can cause excessive friction and stem wear, while under-tightening leads to leaks.

Follow Manufacturer Specifications: Always refer to the valve or packing manufacturer’s guidelines for installation procedures and ring orientation.

Monitor Packing Adjustment: Periodically check and adjust the packing flange bolts to compensate for wear, especially after startup.

Replace When Necessary: Packing is a consumable item. Replace it at appropriate intervals or when signs of leakage or wear appear.

Control valve packing plays a pivotal role in maintaining seal integrity, reducing environmental emissions, and ensuring efficient valve operation. Whether you’re handling corrosive chemicals, high-pressure steam, or sensitive clean-room environments, the choice of packing material must be tailored to your application's specific conditions.

PTFE offers excellent chemical resistance and smooth operation in moderate environments. Graphite excels in high-temperature, high-pressure settings. Metallic or composite packings provide the durability needed in extreme conditions. When combined with best practices for installation and maintenance, proper packing selection can dramatically extend the service life of your control valves and reduce operating costs.

In today's demanding industrial landscape, where performance, compliance, and sustainability are top priorities, valve packing is no longer an afterthought — it’s a strategic decision.