Pneumatic wafer butterfly valves have become a vital component across numerous industries due to their efficient flow control, innovative design, and ease of use. As one of the most popular types of control valves, they are favored for their lightweight construction, quick operation, and reliability. Their unique structural characteristics and adaptable installation options make them a go-to solution for a wide range of applications, from chemical processing to water treatment facilities.

In this article, we will delve into the structure, key features, industry applications, installation procedures, maintenance tips, and operational insights of pneumatic wafer butterfly valves. By the end, you will have a comprehensive understanding of why these valves are an indispensable choice for modern fluid control systems.

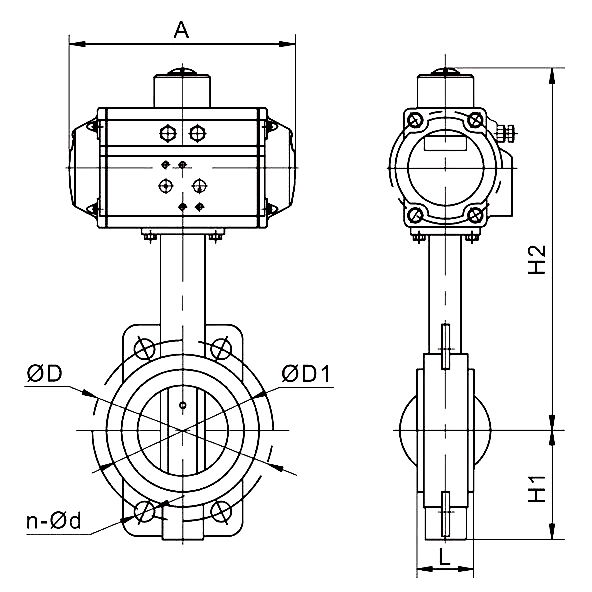

Pneumatic wafer butterfly valves are composed of two main parts: a pneumatic actuator and a butterfly valve body. The term "wafer" refers to the method of installation, where the valve is positioned between two flanges on the pipeline and secured with bolts passing through both the flanges and valve body.

When compressed air enters the pneumatic actuator, it causes the actuator to rotate the valve stem, which in turn rotates the butterfly disc inside the valve body. Depending on the angle of rotation, the valve either allows, throttles, or blocks the flow of fluid through the pipeline.

This efficient mechanical design enables rapid opening and closing, precise flow regulation, and easy automation integration, making pneumatic wafer butterfly valves a cornerstone of modern industrial automation systems.

Pneumatic wafer butterfly valves are loaded with several standout features that make them exceptionally versatile and reliable. Let's explore these features in detail:

The compact and lightweight nature of wafer butterfly valves makes them extremely easy to transport, install, and maintain. Their minimalistic design also reduces the load on piping systems and support structures.

Thanks to the wafer design, these valves can be installed at virtually any position in the pipeline system. They require fewer bolts compared to lug-type valves, resulting in faster installation. Moreover, their simple design enables straightforward maintenance and part replacement.

Pneumatic wafer butterfly valves feature a simple structure, often consisting of just a few key parts: the valve body, disc, stem, seat, and actuator. This simplicity translates to fewer potential failure points, enhancing overall system reliability.

The aerodynamic design of the butterfly disc minimizes resistance, reducing the torque needed to operate the valve. This allows for smaller, more energy-efficient actuators and quicker response times.

Pneumatic wafer butterfly valves operate with a 90-degree rotation from fully closed to fully open. This quick action is ideal for systems requiring fast cycling times and minimizes system downtime during operation or maintenance.

The flow characteristics of wafer butterfly valves approximate a straight-line flow, ensuring minimal pressure loss across the valve when open and excellent throttling capabilities when partially open. Their good control characteristics make them suitable for a variety of flow modulation tasks.

The connection between the butterfly plate (disc) and the valve stem uses a pinless design. This innovation eliminates potential leakage points that could arise with traditional pinned designs, enhancing the valve's integrity and longevity.

The disc's outer circumference adopts a spherical contour, significantly improving the valve's sealing performance. The spherical shape provides a more uniform sealing surface, reducing wear on the seat and prolonging valve service life.

The sealing components of the valve, including the seat and seals, can be replaced individually. This feature extends the overall life of the valve, reduces maintenance costs, and ensures a reliable two-way seal under various operating conditions.

Depending on the operating environment, the butterfly disc can be coated with materials such as nylon or PTFE to enhance chemical resistance, reduce friction, and improve sanitation for food-grade applications.

Besides wafer connections, flange connection designs are also available for specific application needs. Operational modes can include manual handles, electric actuators, or pneumatic actuators, offering tremendous flexibility to meet different automation and control requirements.

The versatility and durability of pneumatic wafer butterfly valves make them a preferred choice across a wide array of industries:

In chemical plants, these valves handle highly corrosive and hazardous fluids, thanks to their robust sealing systems and material options.

Heating, ventilation, and air conditioning (HVAC) systems use pneumatic butterfly valves to regulate air and chilled water flows efficiently, improving energy savings and indoor environmental control.

Pneumatic wafer butterfly valves control flow rates in water treatment facilities, including the distribution of clean water and the management of wastewater.

With appropriate material selections such as PTFE coatings, these valves ensure sanitary, efficient, and contamination-free handling of liquids in food and beverage processing plants.

Pharmaceutical industries use these valves for their hygienic design, ensuring precise control over fluids in production processes under strict sanitary conditions.

In pulp and paper mills, pneumatic wafer butterfly valves regulate the flow of chemicals, water, and slurry, offering long-lasting service in abrasive environments.

To maximize the performance and longevity of pneumatic wafer butterfly valves, careful installation and routine maintenance are essential.

Pipeline Preparation: Ensure that the pipeline flanges are properly aligned before installing the valve. Misalignment can cause undue stress and possible leakage.

Inspection Before Installation: Check that all components of the valve, including the actuator, solenoid valves, and piping connections, are intact, clean, and debris-free.

Correct Valve Positioning: Place the valve in the closed position before connecting it to the pipeline. This step ensures proper alignment and seating.

Align the Actuator: When mounting the actuator onto the valve body, the installation direction (parallel or perpendicular to the valve body) should be carefully considered. Adjust the actuator position slightly if necessary to ensure screw holes are aligned properly before tightening.

Secure Fastening: Use appropriate bolts to fasten the valve and flanges securely, ensuring uniform torque to avoid uneven pressure on the valve body.

Air Pressure Check: During commissioning, the air supply should be maintained at a standard pressure (typically 0.4 to 0.6 MPa).

Manual Operation: Manually operate the solenoid valve during initial testing to observe the opening and closing action of the pneumatic butterfly valve.

Stroke Adjustment: If the valve experiences resistance at the beginning of its opening or closing cycle but functions normally afterward, slight adjustments to the actuator's stroke may be needed. Adjust the stroke adjustment screws at both ends of the cylinder incrementally.

Smooth Operation: The valve must open and close smoothly without binding. The seal should also fully engage to prevent leakage.

Speed Control: Adjustable flow restrictors (often referred to as "X sounders") can fine-tune the opening and closing speed. However, adjustments should be moderate; overly restricted flow can prevent the actuator from moving the valve disc.

Routine Inspection: Regularly check the seals, actuator, and solenoid valve for signs of wear, damage, or contamination.

Lubrication: Lubricate moving parts periodically to maintain smooth operation, especially in harsh operating environments.

Seal Replacement: Replace sealing parts as needed to prevent leakage and maintain optimal performance.

Actuator Maintenance: Inspect pneumatic actuators for leaks or irregular performance. Clean air supply lines and solenoid valves regularly.

Documentation: Maintain detailed service records for each valve installation. Tracking maintenance activities helps anticipate future issues and extends valve service life.

Pneumatic wafer butterfly valves stand out for their efficiency, reliability, and flexibility across various industrial applications. Their innovative design ensures rapid operation, excellent sealing, and easy installation, while their adaptability to different connection types and coatings broadens their usability in demanding environments.

Whether used in chemical processing, water treatment, HVAC systems, or food and beverage industries, pneumatic wafer butterfly valves consistently deliver outstanding performance. Proper installation, routine maintenance, and careful commissioning will ensure they operate flawlessly for years, contributing to safer, more efficient fluid control systems.

Choosing a high-quality pneumatic wafer butterfly valve, along with following best practices in operation and maintenance, is essential for maximizing the return on your investment and achieving optimal system performance.