Ball Valve vs Control Valve

On this page

Valves play a crucial role in various industries, from oil and gas to pharmaceuticals, by controlling the flow and pressure of fluids and gases within a system. Among the myriad of valve types, ball valves and control valves are two of the most commonly used. Each serves distinct purposes and offers unique advantages and disadvantages. This article delves into the characteristics of these valves, their applications, and how to select the right one for your business needs.

Control valves are designed to regulate the flow, pressure, temperature, or liquid level in a process system. These valves achieve precise control through a variable opening that can be adjusted by actuators, which respond to signals from a control system. Control valves are essential in processes where accuracy and reliability are critical, such as in chemical processing, power generation, and water treatment.

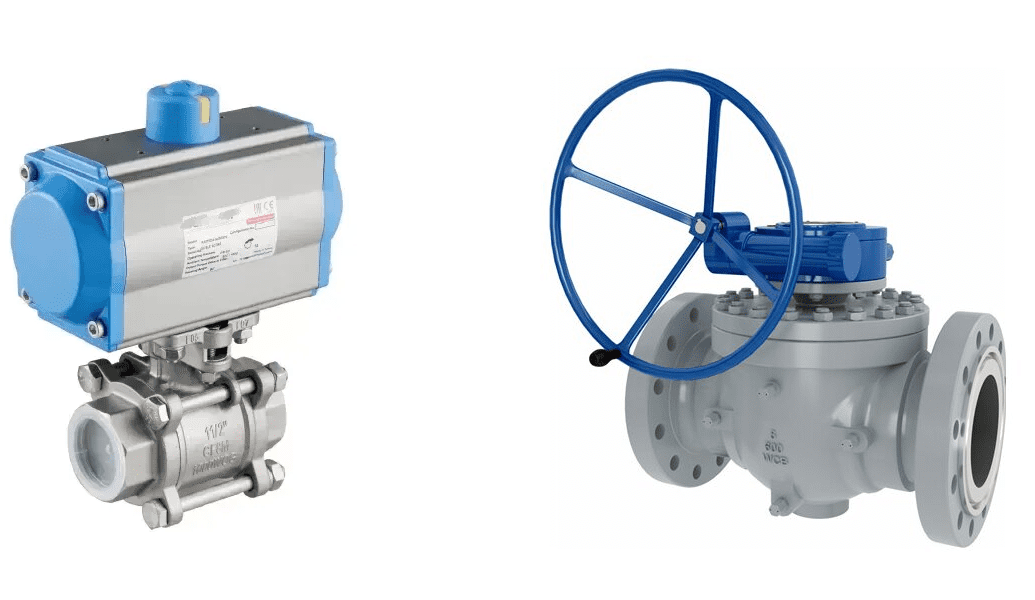

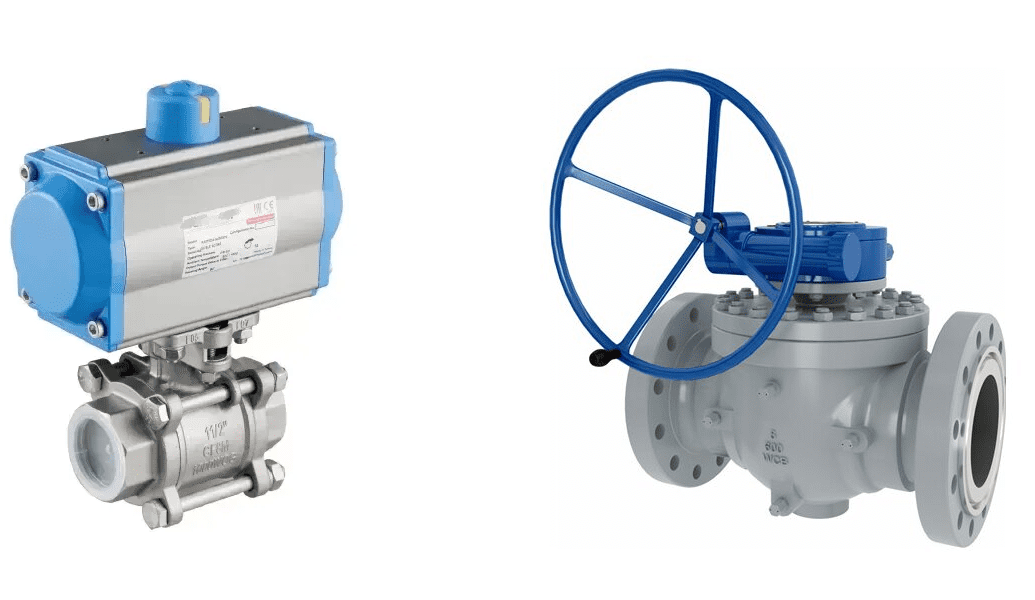

Control valves come in various types, including globe valves, butterfly valves, and ball valves configured for control purposes. Each type has its own unique advantages, such as the linear flow characteristics of globe valves, which make them ideal for throttling applications. Control valves are often equipped with positioners and advanced control systems to enhance their precision and responsiveness. Ball valves, on the other hand, are primarily used for on/off control of fluid flow. They operate by rotating a spherical disc (the ball) with a hole through its center. When the hole aligns with the flow path, the valve is open; when it is perpendicular, the valve is closed. This simple yet effective mechanism provides quick and reliable shut-off capabilities.

Ball valves are known for their durability, ease of operation, and tight sealing, making them suitable for a wide range of applications, including water and gas pipelines, oil and petrochemical industries, and HVAC systems. They are available in different designs, such as floating ball, trunnion-mounted ball, and multi-port configurations, each catering to specific operational needs. The primary difference between control valves and ball valves lies in their functionality. Control valves are designed for precise regulation of flow and pressure, making them indispensable in systems requiring fine-tuned control. They can modulate the flow rate to maintain desired process conditions, which is essential in complex and sensitive operations.

Conversely, ball valves are mainly used for isolation and on/off control. They are not typically used for flow modulation due to their relatively coarse control capabilities. However, ball valves excel in applications where quick shut-off and reliable sealing are necessary.

Another key difference is the construction and mechanism. Control valves often feature more complex designs with actuators and positioners, whereas ball valves have a simpler mechanism with fewer moving parts, leading to lower maintenance requirements. Ball valves are widely used in various industries due to their robustness and versatility. Some common applications include: Ball valves are used for isolation and shut-off in pipelines and processing systems due to their ability to handle high pressures and temperatures. They are used in systems requiring tight sealing and quick operation to control water flow and prevent leaks.

Chemical and Petrochemical Industries

Ball valves are employed in processes that require handling aggressive chemicals and ensuring reliable isolation. In heating, ventilation, and air conditioning systems, ball valves are used for controlling the flow of water and refrigerants. Control valves are essential in processes where precise control over fluid dynamics is required. Some of their key applications include: Control valves regulate the flow of reactants and products, ensuring optimal reaction conditions and product quality. They are used to control steam and water flow in power plants, contributing to efficient and safe operation. Control valves maintain accurate control over process conditions, which is crucial for producing consistent and high-quality pharmaceutical products. In this industry, control valves manage the flow of ingredients and process fluids, ensuring consistent product quality and safety. Selecting the right valve for your business depends on several factors, including the nature of your process, operating conditions, and specific requirements. Here are some key considerations: Determine whether you need precise control (control valve) or simple on/off operation (ball valve). Consider the type of fluid (liquid, gas, slurry), its temperature, pressure, and corrosiveness.

Operating Environment

Evaluate the environmental conditions, such as temperature extremes, humidity, and exposure to corrosive substances. Assess the maintenance requirements and choose a valve that aligns with your maintenance capabilities and schedule. Balance the initial cost of the valve with its expected lifespan, maintenance costs, and operational efficiency. Both ball valves and control valves play integral roles in industrial processes, each offering unique advantages depending on the application. Understanding the differences between these valves and their specific uses will help you make informed decisions to optimize your system’s performance and reliability. By carefully evaluating your process requirements and operating conditions, you can select the right valve to ensure efficiency, safety, and cost-effectiveness in your operations.

Control valves are designed to regulate the flow, pressure, temperature, or liquid level in a process system. These valves achieve precise control through a variable opening that can be adjusted by actuators, which respond to signals from a control system. Control valves are essential in processes where accuracy and reliability are critical, such as in chemical processing, power generation, and water treatment.

Control valves come in various types, including globe valves, butterfly valves, and ball valves configured for control purposes. Each type has its own unique advantages, such as the linear flow characteristics of globe valves, which make them ideal for throttling applications. Control valves are often equipped with positioners and advanced control systems to enhance their precision and responsiveness. Ball valves, on the other hand, are primarily used for on/off control of fluid flow. They operate by rotating a spherical disc (the ball) with a hole through its center. When the hole aligns with the flow path, the valve is open; when it is perpendicular, the valve is closed. This simple yet effective mechanism provides quick and reliable shut-off capabilities.

Ball valves are known for their durability, ease of operation, and tight sealing, making them suitable for a wide range of applications, including water and gas pipelines, oil and petrochemical industries, and HVAC systems. They are available in different designs, such as floating ball, trunnion-mounted ball, and multi-port configurations, each catering to specific operational needs. The primary difference between control valves and ball valves lies in their functionality. Control valves are designed for precise regulation of flow and pressure, making them indispensable in systems requiring fine-tuned control. They can modulate the flow rate to maintain desired process conditions, which is essential in complex and sensitive operations.

Conversely, ball valves are mainly used for isolation and on/off control. They are not typically used for flow modulation due to their relatively coarse control capabilities. However, ball valves excel in applications where quick shut-off and reliable sealing are necessary.

Another key difference is the construction and mechanism. Control valves often feature more complex designs with actuators and positioners, whereas ball valves have a simpler mechanism with fewer moving parts, leading to lower maintenance requirements. Ball valves are widely used in various industries due to their robustness and versatility. Some common applications include: Ball valves are used for isolation and shut-off in pipelines and processing systems due to their ability to handle high pressures and temperatures. They are used in systems requiring tight sealing and quick operation to control water flow and prevent leaks.

Chemical and Petrochemical Industries

Ball valves are employed in processes that require handling aggressive chemicals and ensuring reliable isolation. In heating, ventilation, and air conditioning systems, ball valves are used for controlling the flow of water and refrigerants. Control valves are essential in processes where precise control over fluid dynamics is required. Some of their key applications include: Control valves regulate the flow of reactants and products, ensuring optimal reaction conditions and product quality. They are used to control steam and water flow in power plants, contributing to efficient and safe operation. Control valves maintain accurate control over process conditions, which is crucial for producing consistent and high-quality pharmaceutical products. In this industry, control valves manage the flow of ingredients and process fluids, ensuring consistent product quality and safety. Selecting the right valve for your business depends on several factors, including the nature of your process, operating conditions, and specific requirements. Here are some key considerations: Determine whether you need precise control (control valve) or simple on/off operation (ball valve). Consider the type of fluid (liquid, gas, slurry), its temperature, pressure, and corrosiveness.

Operating Environment

Evaluate the environmental conditions, such as temperature extremes, humidity, and exposure to corrosive substances. Assess the maintenance requirements and choose a valve that aligns with your maintenance capabilities and schedule. Balance the initial cost of the valve with its expected lifespan, maintenance costs, and operational efficiency. Both ball valves and control valves play integral roles in industrial processes, each offering unique advantages depending on the application. Understanding the differences between these valves and their specific uses will help you make informed decisions to optimize your system’s performance and reliability. By carefully evaluating your process requirements and operating conditions, you can select the right valve to ensure efficiency, safety, and cost-effectiveness in your operations.