What is Eccentric Rotary Control Valve?

On this page

In the world of industrial automation and control systems, valves play a crucial role in regulating the flow of fluids and gases. Among various types of valves, the eccentric rotary control valve stands out for its unique design and functionality. This article delves into the details of eccentric rotary control valves, exploring their structure, features, and working principles.

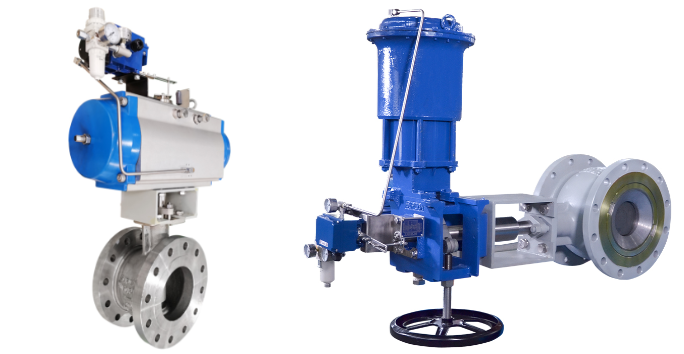

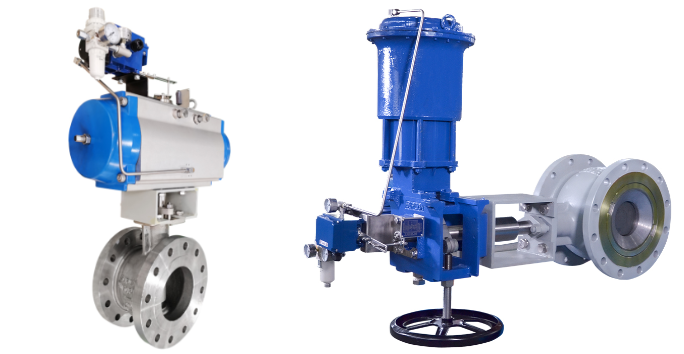

An eccentric rotary control valve is a type of rotary valve used to control the flow of fluids by varying the size of the flow passage. Unlike conventional rotary valves, which rotate around a central axis, eccentric rotary control valves have an off-center or eccentric rotation axis. This design allows for more precise control over the flow and reduces wear and tear, making them ideal for demanding industrial applications. The structure of an eccentric rotary control valve is characterized by its unique design elements that differentiate it from other types of valves. Key components include: The main casing that houses the internal components of the valve. It is typically made from robust materials such as stainless steel or carbon steel to withstand harsh industrial environments. The shaft that rotates to open or close the valve. In an eccentric rotary control valve, this shaft is offset from the center, providing the eccentric rotation. Attached to the rotary shaft, the disk is the component that comes into contact with the fluid flow. The shape and design of the disk play a crucial role in controlling the flow rate. The mechanism that drives the rotation of the shaft and disk. Actuators can be electric, pneumatic, or hydraulic, depending on the specific application and control requirements. The surface against which the disk seals when the valve is closed. The seat is designed to provide a tight seal, preventing any leakage when the valve is in the closed position. These components ensure smooth operation and prevent leaks around the rotary shaft. Eccentric rotary control valves offer several features that make them advantageous for various industrial applications: The eccentric rotation allows for finer adjustments to the flow rate, providing better control over the process. The off-center rotation minimizes friction between the disk and seat, reducing wear and extending the valve's lifespan. The design ensures a tight seal when the valve is closed, preventing leaks and enhancing operational safety. These valves can handle a wide range of fluids, including liquids, gases, and slurries, making them suitable for diverse applications. The eccentric design reduces the torque required to operate the valve, making it more energy-efficient and easier to control. Eccentric rotary control valves are typically more compact than other types of control valves, saving space and simplifying installation. The working principle of an eccentric rotary control valve revolves around its off-center rotary motion. When the actuator receives a signal to open or close the valve, it rotates the shaft. Because the shaft is eccentric, this rotation causes the disk to move in a non-linear path, gradually increasing or decreasing the flow passage.

Here’s a step-by-step breakdown of the working principle: The actuator receives a control signal from the process control system, indicating the desired position of the valve (open, closed, or somewhere in between). The actuator rotates the eccentric shaft according to the control signal. The amount of rotation determines the position of the disk relative to the flow passage. As the shaft rotates, the disk moves in a way that either opens or restricts the flow passage. The eccentric design ensures that the disk moves away from the seat more gradually, providing finer control over the flow rate. The position of the disk relative to the flow passage determines the flow rate. When fully open, the disk allows maximum flow. As the disk moves toward the closed position, the flow rate decreases until the disk fully contacts the seat, providing a tight shut-off. In many applications, the valve is part of a feedback loop where sensors monitor the flow rate, pressure, or other process variables. The control system adjusts the valve position based on real-time data to maintain optimal process conditions. Eccentric rotary control valves are a vital component in many industrial control systems, offering precise flow regulation, reduced wear, and reliable performance. Their unique design and features make them suitable for a wide range of applications, ensuring efficient and safe operation in demanding environments. Understanding their structure, features, and working principles helps in selecting the right valve for specific industrial needs and ensures optimal performance and longevity.

An eccentric rotary control valve is a type of rotary valve used to control the flow of fluids by varying the size of the flow passage. Unlike conventional rotary valves, which rotate around a central axis, eccentric rotary control valves have an off-center or eccentric rotation axis. This design allows for more precise control over the flow and reduces wear and tear, making them ideal for demanding industrial applications. The structure of an eccentric rotary control valve is characterized by its unique design elements that differentiate it from other types of valves. Key components include: The main casing that houses the internal components of the valve. It is typically made from robust materials such as stainless steel or carbon steel to withstand harsh industrial environments. The shaft that rotates to open or close the valve. In an eccentric rotary control valve, this shaft is offset from the center, providing the eccentric rotation. Attached to the rotary shaft, the disk is the component that comes into contact with the fluid flow. The shape and design of the disk play a crucial role in controlling the flow rate. The mechanism that drives the rotation of the shaft and disk. Actuators can be electric, pneumatic, or hydraulic, depending on the specific application and control requirements. The surface against which the disk seals when the valve is closed. The seat is designed to provide a tight seal, preventing any leakage when the valve is in the closed position. These components ensure smooth operation and prevent leaks around the rotary shaft. Eccentric rotary control valves offer several features that make them advantageous for various industrial applications: The eccentric rotation allows for finer adjustments to the flow rate, providing better control over the process. The off-center rotation minimizes friction between the disk and seat, reducing wear and extending the valve's lifespan. The design ensures a tight seal when the valve is closed, preventing leaks and enhancing operational safety. These valves can handle a wide range of fluids, including liquids, gases, and slurries, making them suitable for diverse applications. The eccentric design reduces the torque required to operate the valve, making it more energy-efficient and easier to control. Eccentric rotary control valves are typically more compact than other types of control valves, saving space and simplifying installation. The working principle of an eccentric rotary control valve revolves around its off-center rotary motion. When the actuator receives a signal to open or close the valve, it rotates the shaft. Because the shaft is eccentric, this rotation causes the disk to move in a non-linear path, gradually increasing or decreasing the flow passage.

Here’s a step-by-step breakdown of the working principle: The actuator receives a control signal from the process control system, indicating the desired position of the valve (open, closed, or somewhere in between). The actuator rotates the eccentric shaft according to the control signal. The amount of rotation determines the position of the disk relative to the flow passage. As the shaft rotates, the disk moves in a way that either opens or restricts the flow passage. The eccentric design ensures that the disk moves away from the seat more gradually, providing finer control over the flow rate. The position of the disk relative to the flow passage determines the flow rate. When fully open, the disk allows maximum flow. As the disk moves toward the closed position, the flow rate decreases until the disk fully contacts the seat, providing a tight shut-off. In many applications, the valve is part of a feedback loop where sensors monitor the flow rate, pressure, or other process variables. The control system adjusts the valve position based on real-time data to maintain optimal process conditions. Eccentric rotary control valves are a vital component in many industrial control systems, offering precise flow regulation, reduced wear, and reliable performance. Their unique design and features make them suitable for a wide range of applications, ensuring efficient and safe operation in demanding environments. Understanding their structure, features, and working principles helps in selecting the right valve for specific industrial needs and ensures optimal performance and longevity.