In the realm of industrial valves, precision and efficiency are paramount. Among the array of valve types available, two commonly utilized options stand out: V-port ball control valves and globe control valves. Both serve critical roles in regulating fluid flow within various industries, yet they possess distinct characteristics that cater to specific applications.

V-port ball control valves feature a unique V-shaped port within the ball, designed to offer precise control over flow rates and fluid media. This innovative design allows for accurate modulation of flow, making V-port ball valves ideal for applications that require fine-tuned control. They are especially beneficial in industries such as chemical processing and food manufacturing. The V-port design enhances flow capacity and reduces turbulence, leading to increased efficiency and minimized energy consumption.

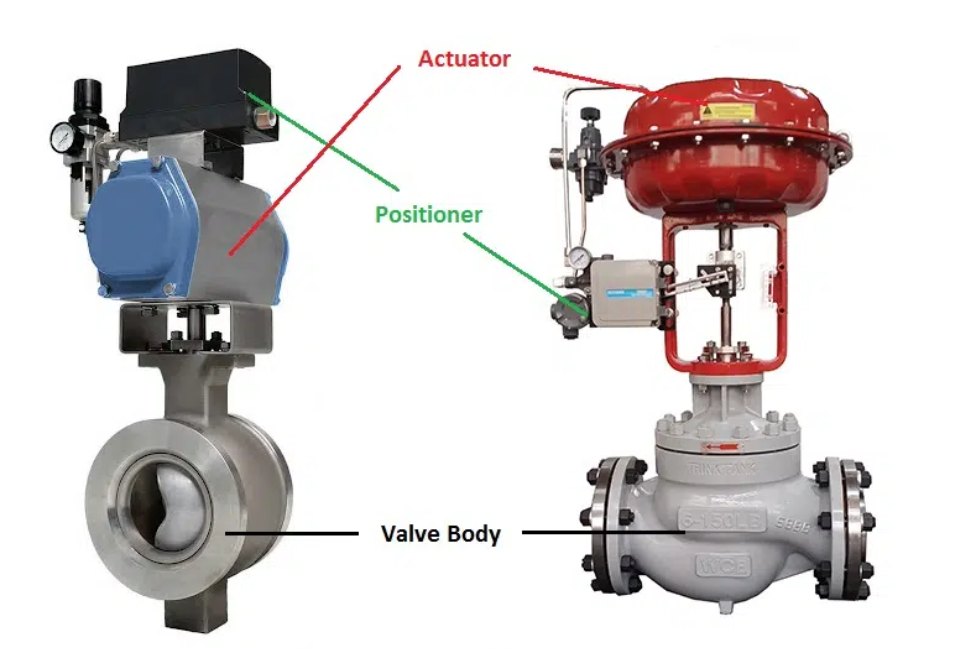

V-Port Ball Valve (rotary) vs Globe Contro Valve (linear)

Globe control valves, on the other hand, are known for their versatility and reliability across a broad range of operating conditions. With a globe-shaped body and a linear motion mechanism, these valves excel at regulating flow rates and pressure within pipelines. They are commonly used in industries like oil and gas, power generation, and water treatment, where robustness and durability are essential. Globe valves' design ensures dependable performance and durability in diverse environments.

The primary distinction between V-port ball control valves and globe control valves lies in their internal mechanisms and flow characteristics. V-port ball valves use a rotating ball with a V-shaped port to modulate flow, offering precise control over flow rates. In contrast, globe valves employ a linear motion mechanism, where a disc moves perpendicularly to the flow direction to regulate fluid passage. This difference affects flow capacity, pressure drop, and control accuracy, influencing their suitability for various applications.

V-port ball control valves are particularly suited for applications requiring precise flow control and high rangeability, such as chemical processing, pharmaceutical manufacturing, and wastewater treatment. Their ability to provide accurate modulation of flow rates makes them ideal for processes that demand strict adherence to specific parameters.

Conversely, globe control valves are valued for their versatility in handling high-pressure, high-temperature, and abrasive fluids. Their robust construction and linear motion mechanism make them suitable for use in oil refineries, power plants, petrochemical facilities, and HVAC systems, where they play a critical role in regulating fluid flow and maintaining system efficiency.

Both V-port ball control valves and globe control valves require careful consideration during installation and maintenance. Factors such as piping configuration, valve sizing, and actuation requirements must be addressed to ensure optimal performance and longevity. Routine maintenance and periodic inspections are also recommended to detect and resolve potential issues promptly.

While V-port ball control valves and globe control valves serve similar functions as fluid flow regulators, they possess distinct characteristics that cater to specific industry requirements and operational conditions. Understanding these differences is crucial for selecting the most suitable valve type for a given application, ensuring efficient and reliable operation across diverse industrial settings.