Commonly recognized as the final control element, the globe control valve incorporates a pneumatic mechanism that converts the control signal from the transmitter into motion, thereby managing the flow of process fluid. Valves constitute approximately 15 percent of total expenditures on products and machinery in the refining or chemical manufacturing sector. The globe control valve stands out as a prevalent choice for endpoint screening in process control industries.

The globe control valve regulates the flow of moving liquids like air, steam, water, or chemicals, facilitating interaction with loads and maintaining the regulated period variable close to the desired fixed point. Often overlooked, these valves are crucial components of control loops, possibly due to engineers' unfamiliarity with various measurements and engineering disciplines like fluid dynamics, metallurgy, noise reduction, piping, and vessel construction.

Each control loop typically comprises a process status sensor, transmitter, and controller, comparing the received signal to the desired level and sending correction signals to the end-control device—the final component of the loop. Analogous to the hands of a control system, this valve is the essential yet lesser-known element of automatic control devices, sometimes overlooked due to our reliance on systems and computers.

Why are Control Valves Crucial in Process Design?

Control valves play a pivotal role not only in normal operations but also in ensuring safety. Any form of loss, whether it's production loss or its impact on personnel or the environment, is undesirable.

During the design of control valves, meticulous attention must be given to all possible combinations of flow rate, pressure/pressure drop, temperature, and compositions. Engineers often prioritize major process equipment, sometimes overlooking the significance of control valves and control logic. Before making final decisions to modify the system, it's essential to assess control valves whenever any parameter is altered.

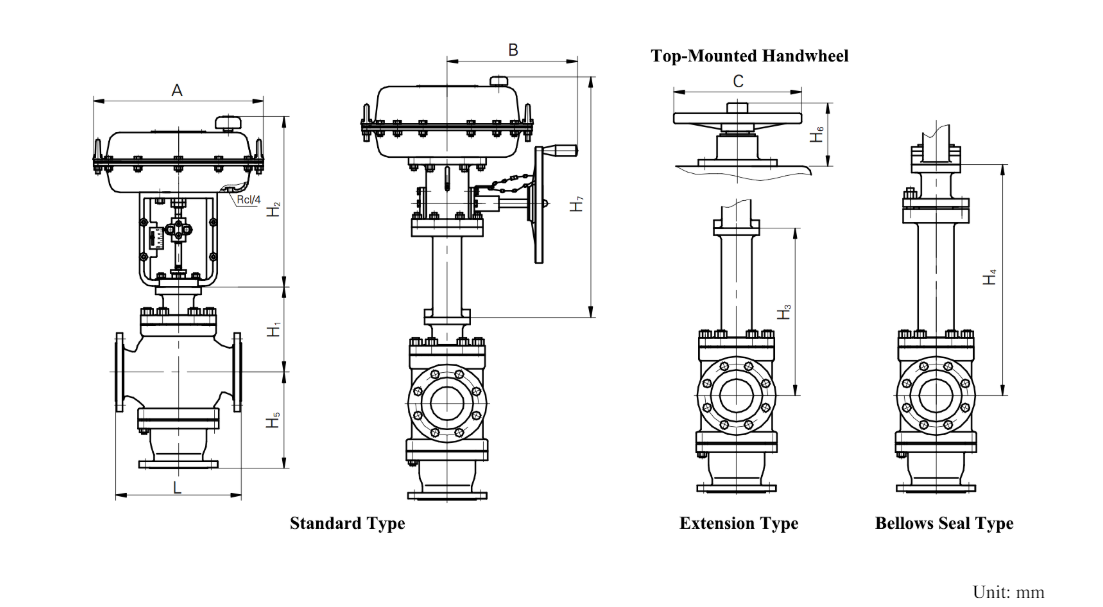

DN20-DN350 External Dimensions for Standard, Extension and Bellows