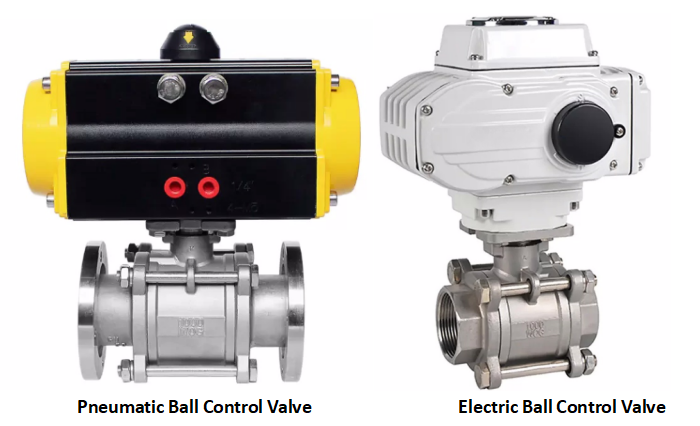

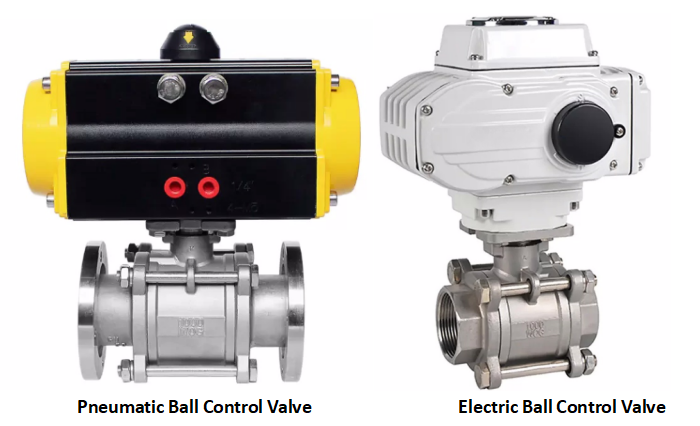

Electric Ball Control Valves vs Pneumatic Ball Control Valves

On this page

In industrial settings, control valves are essential components for regulating fluid flow. Among the various types available, ball control valves are particularly popular due to their reliable performance and versatility. When it comes to actuation methods, electric and pneumatic ball control valves are the most commonly used. This article delves into the key differences between these two types of valves, examining their advantages, disadvantages, and ideal applications.

A ball control valve uses a spherical ball with a hole through its center to control fluid flow. Rotating the ball allows for precise regulation, from full flow to complete shut-off. These valves are valued for their durability, low maintenance requirements, and tight sealing capabilities, making them suitable for various industries, including oil and gas, chemical processing, and water treatment. Electric ball control valves are actuated by an electric motor. This motor rotates the ball within the valve, adjusting the flow based on control signals. Here are some of the primary benefits and drawbacks of electric ball control valves: Electric actuators offer high precision, allowing for fine adjustments to the valve position. This results in accurate control over fluid flow, which is crucial in applications requiring precise regulation. Electric valves can be easily integrated into automated systems and controlled remotely via digital signals. This makes them ideal for modern, automated industrial processes. Once in position, electric actuators consume minimal power, making them energy-efficient compared to continuous air consumption in pneumatic systems. Electric actuators are generally more expensive upfront than pneumatic actuators, both in terms of initial investment and potential maintenance costs. Electric actuators can be slower to respond than pneumatic ones, which may be a drawback in applications requiring rapid valve adjustments. The electronic components can be more complex and may require more sophisticated maintenance compared to simpler pneumatic systems. Pneumatic ball control valves are actuated by compressed air. Air pressure moves the actuator, rotating the ball within the valve to regulate flow. The key benefits and limitations of pneumatic ball control valves are as follows: Pneumatic actuators typically offer quicker response times than electric actuators, making them suitable for applications where rapid adjustments are necessary. Pneumatic systems are generally simpler and more robust, with fewer components that can fail. This results in high reliability and ease of maintenance. Initial costs for pneumatic systems are often lower than electric systems, particularly in facilities that already use compressed air for other processes. Pneumatic systems require a continuous supply of compressed air, which can be less energy-efficient and more costly in the long run compared to the static energy use of electric actuators. The operation of pneumatic actuators can be noisier than electric actuators, which may be a consideration in noise-sensitive environments. While pneumatic actuators are reliable, they may not offer the same level of control precision as electric actuators, which can be a limitation in applications requiring fine adjustments. The decision between electric and pneumatic ball control valves depends on several factors, including the specific requirements of the application, cost considerations, and the existing infrastructure. If the application requires high precision and integration into an automated control system, electric ball control valves are likely the better choice. Their ability to provide fine adjustments and be controlled digitally makes them ideal for complex processes. For applications that prioritize quick response times and robustness, pneumatic ball control valves are preferable. Their simplicity and fast actuation make them suitable for operations where speed and reliability are critical. Existing infrastructure and cost considerations also play a significant role. Facilities with an existing compressed air system may find pneumatic valves more cost-effective, while those with advanced digital control systems might benefit more from electric valves. Both electric and pneumatic ball control valves have their distinct advantages and are suited to different industrial applications. Understanding the specific needs of your operation and the characteristics of each valve type will help in making an informed decision. Whether prioritizing precision, speed, cost, or ease of integration, choosing the right valve will enhance efficiency and reliability in your fluid control system.

A ball control valve uses a spherical ball with a hole through its center to control fluid flow. Rotating the ball allows for precise regulation, from full flow to complete shut-off. These valves are valued for their durability, low maintenance requirements, and tight sealing capabilities, making them suitable for various industries, including oil and gas, chemical processing, and water treatment. Electric ball control valves are actuated by an electric motor. This motor rotates the ball within the valve, adjusting the flow based on control signals. Here are some of the primary benefits and drawbacks of electric ball control valves: Electric actuators offer high precision, allowing for fine adjustments to the valve position. This results in accurate control over fluid flow, which is crucial in applications requiring precise regulation. Electric valves can be easily integrated into automated systems and controlled remotely via digital signals. This makes them ideal for modern, automated industrial processes. Once in position, electric actuators consume minimal power, making them energy-efficient compared to continuous air consumption in pneumatic systems. Electric actuators are generally more expensive upfront than pneumatic actuators, both in terms of initial investment and potential maintenance costs. Electric actuators can be slower to respond than pneumatic ones, which may be a drawback in applications requiring rapid valve adjustments. The electronic components can be more complex and may require more sophisticated maintenance compared to simpler pneumatic systems. Pneumatic ball control valves are actuated by compressed air. Air pressure moves the actuator, rotating the ball within the valve to regulate flow. The key benefits and limitations of pneumatic ball control valves are as follows: Pneumatic actuators typically offer quicker response times than electric actuators, making them suitable for applications where rapid adjustments are necessary. Pneumatic systems are generally simpler and more robust, with fewer components that can fail. This results in high reliability and ease of maintenance. Initial costs for pneumatic systems are often lower than electric systems, particularly in facilities that already use compressed air for other processes. Pneumatic systems require a continuous supply of compressed air, which can be less energy-efficient and more costly in the long run compared to the static energy use of electric actuators. The operation of pneumatic actuators can be noisier than electric actuators, which may be a consideration in noise-sensitive environments. While pneumatic actuators are reliable, they may not offer the same level of control precision as electric actuators, which can be a limitation in applications requiring fine adjustments. The decision between electric and pneumatic ball control valves depends on several factors, including the specific requirements of the application, cost considerations, and the existing infrastructure. If the application requires high precision and integration into an automated control system, electric ball control valves are likely the better choice. Their ability to provide fine adjustments and be controlled digitally makes them ideal for complex processes. For applications that prioritize quick response times and robustness, pneumatic ball control valves are preferable. Their simplicity and fast actuation make them suitable for operations where speed and reliability are critical. Existing infrastructure and cost considerations also play a significant role. Facilities with an existing compressed air system may find pneumatic valves more cost-effective, while those with advanced digital control systems might benefit more from electric valves. Both electric and pneumatic ball control valves have their distinct advantages and are suited to different industrial applications. Understanding the specific needs of your operation and the characteristics of each valve type will help in making an informed decision. Whether prioritizing precision, speed, cost, or ease of integration, choosing the right valve will enhance efficiency and reliability in your fluid control system.