Electric Ball Valve vs. Solenoid Valve: A Comprehensive Comparison

On this page

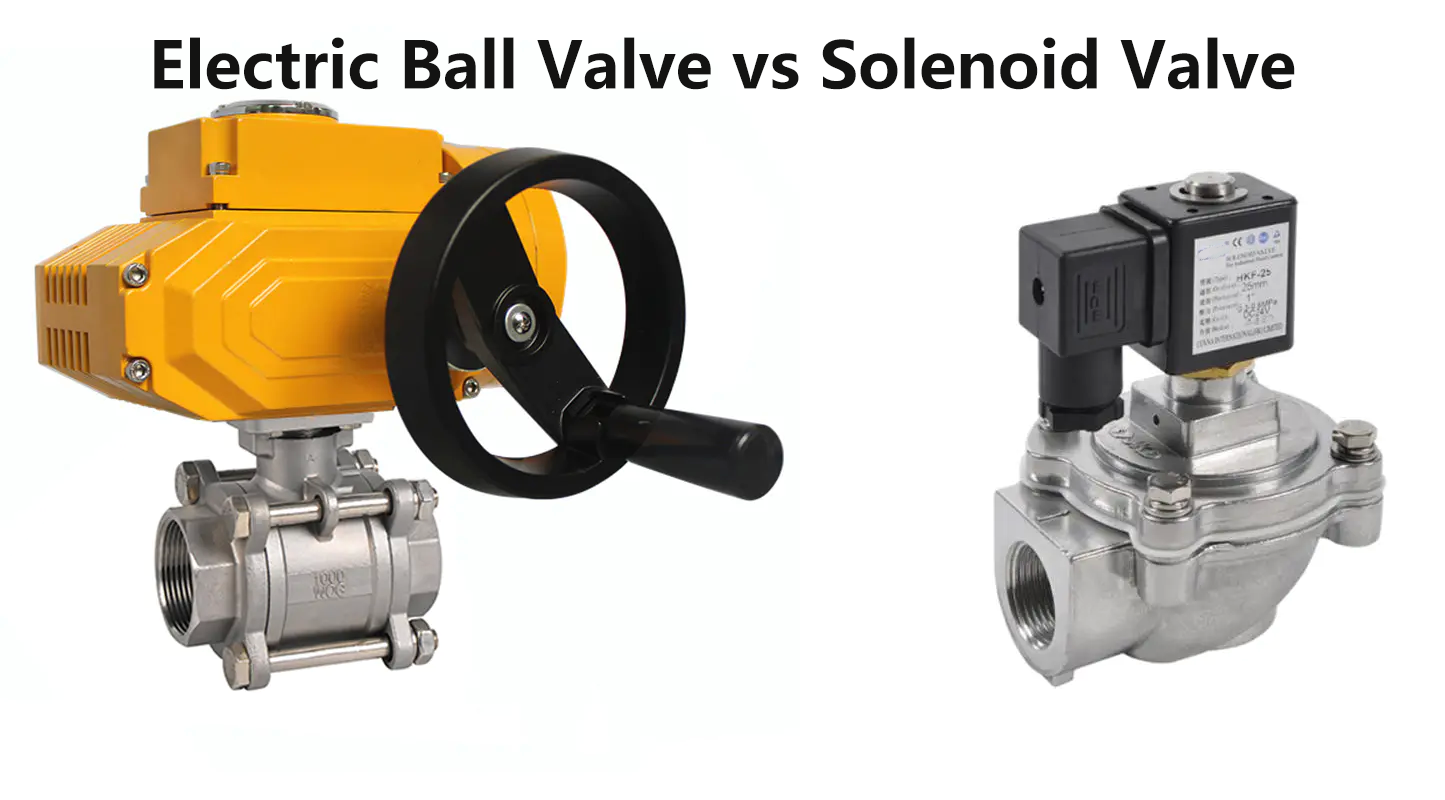

In the realm of fluid control systems, selecting the right valve type is crucial for optimizing performance, reliability, and efficiency. Among the many options available, electric ball valves and solenoid valves stand out as two of the most widely used types. Each valve type offers unique advantages and is suited for specific applications. This article delves into the key differences between electric ball control valves and solenoid valves, providing a comprehensive comparison to help you make an informed decision for your specific needs.

Electric ball valves operate using an electric actuator that rotates a ball with a hole through its center to control fluid flow. When the ball is rotated so that the hole aligns with the flow direction, the valve is open; when the ball is rotated 90 degrees, the valve is closed. This mechanism allows for precise control over the flow of liquids or gases.

In contrast, solenoid valves use an electromagnetic solenoid coil to move a plunger, which opens or closes the valve. When an electrical current passes through the coil, it generates a magnetic field that pulls the plunger, thus opening the valve. Releasing the current allows the plunger to return to its original position, closing the valve. Solenoid valves offer quick switching capabilities but are generally limited to on/off control. Electric ball valves are highly versatile and can be used in a wide range of applications, from industrial automation and water treatment to HVAC systems and oil and gas operations. Their ability to provide precise flow control makes them ideal for processes requiring variable flow rates and specific control parameters.

Solenoid valves, on the other hand, are best suited for applications requiring rapid switching and simple on/off control. They are commonly used in irrigation systems, pneumatic controls, and small-scale fluid dispensing systems. However, their limited flow control capabilities make them less suitable for applications requiring precise modulation. Electric ball valves are known for their durability and long service life. The robust construction of the valve and actuator components allows them to withstand harsh environments, high pressures, and corrosive fluids. Additionally, electric ball valves typically require less frequent maintenance compared to solenoid valves, making them a cost-effective choice for long-term use.

Solenoid valves, while reliable, may require more frequent maintenance due to the potential for wear and tear on the solenoid coil and plunger components. They are also more susceptible to issues such as coil burnout and plunger sticking, particularly in demanding or dirty environments. Energy consumption is a critical consideration in valve selection, especially for systems operating continuously. Electric ball valves, despite their initial higher energy usage during actuation, generally consume less energy overall. This is because they only use power when changing states, whereas they do not require continuous power to maintain their position.

Solenoid valves, however, typically consume more energy because they require a constant electrical current to remain in an open or closed position. This continuous power draw can add up over time, particularly in systems where valves remain in one position for extended periods. Electric ball valves offer superior control and integration capabilities in automated systems. They can be easily integrated with various control systems, including programmable logic controllers (PLCs) and building management systems (BMS), providing precise and responsive control over fluid flow. The ability to modulate flow rates makes electric ball valves ideal for complex processes requiring fine-tuned adjustments.

Solenoid valves, while capable of rapid response times, are limited to binary on/off control. This limitation restricts their use in applications requiring nuanced flow adjustments. However, their simplicity makes them easy to install and control in basic automation setups. Choosing between an electric ball valve and a solenoid valve depends largely on the specific requirements of your application. Electric ball valves excel in scenarios requiring precise flow control, durability, and energy efficiency, making them suitable for a wide range of industrial and commercial applications. Solenoid valves, with their rapid switching capabilities and straightforward design, are ideal for applications needing quick, on/off control.

By understanding the key differences and advantages of each valve type, you can make a well-informed decision that optimizes the performance and efficiency of your fluid control system. Whether you prioritize precision, durability, or simplicity, selecting the right valve is essential for achieving optimal results in your specific application.